Patents

Literature

38 results about "Vinylchloride polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastisol compositions comprising vinyl chloride polymers and mixtures of aromatic and aliphatic esters of diols as plasticizers

InactiveUS6933337B2Improve solubilityReduce the temperatureOrganic compound preparationCarboxylic acid esters preparationCarboxylic acidDiol

Mixtures of esters produced by reacting a mixture of aromatic and aliphatic monocarboxylic acids with a diol containing from 2 to 12 carbon atoms are effective plasticizers for plastisols containing dispersion grade polymers of vinyl chloride. The freezing point of the present ester mixtures and their efficacy as plasticizers can be varied by adjusting the type and relative concentration of the aliphatic acid used to prepare the plasticizer. The ester mixtures can also be used as plasticizers for other organic polymers.

Owner:EASTMAN SPECIALITIES HLDG CORP

Phosphate surfactant and method for preparing trifluorochlor oethylene polymer

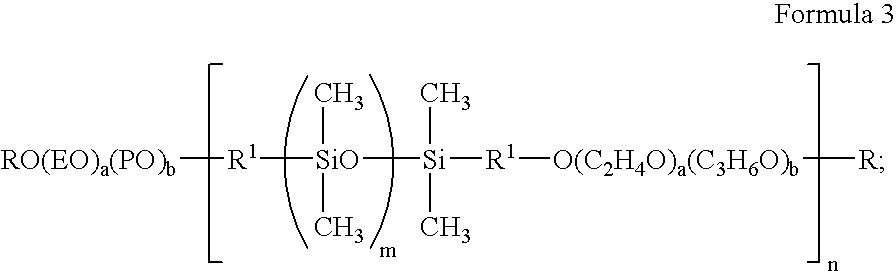

The invention discloses a phosphate surfactant, of which the chemical formula is: H-(CF2)m-CH2-O-(CH2CH2O)n-PO(OM)2, wherein m is equal to 2, 4, 6 or 8, n is equal to 0 or 1, and M is NH4+ or Na+. The invention also discloses a method for preparing trifluorochlor oethylene polymer emulsion or solid with the phosphate surfactant as an emulsifier. The surfactant can be used for emulsion polymerization of fluoride-containing monomer. Used as the emulsifier, the surfactant can achieve a high polymerization rate, good dispersion stability, high yield, excellent copolymerization performance and / or multiple particle sizes (including small particle size). Besides, the method can realize polymerization by only using conventional equipment, is easy and convenient to operate and has a low cost, and does not cause environmental pollution during and after reaction.

Owner:UNIV OF JINAN

Preparation method of vinylidene chloride polymer base mesopore-micropore composite porous charcoal

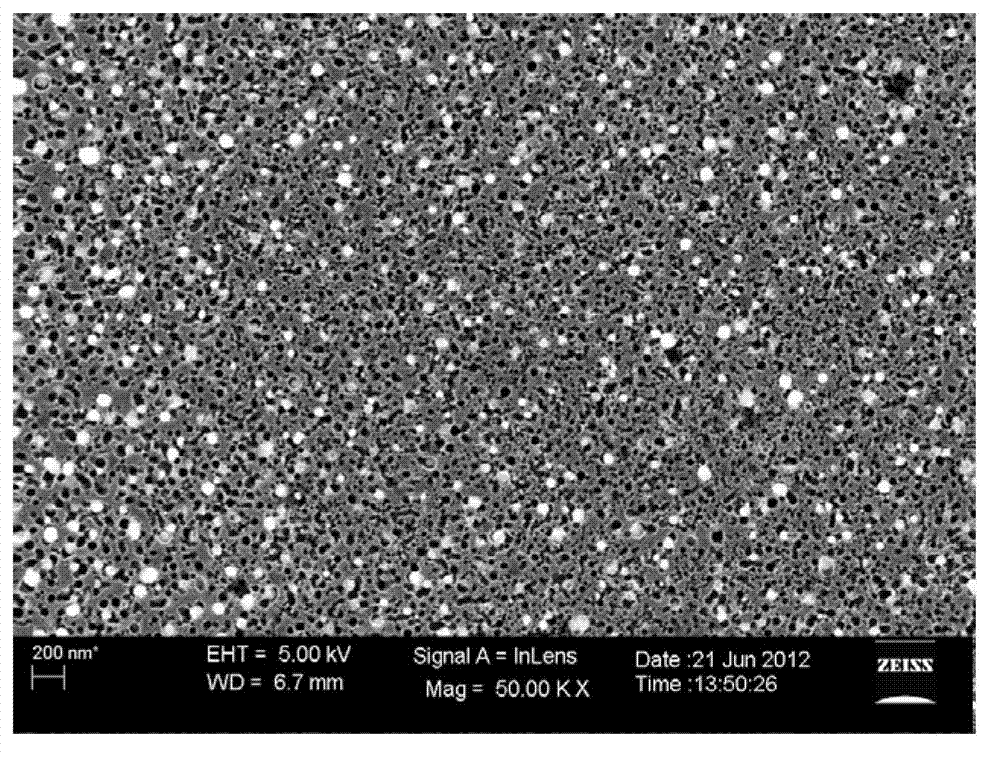

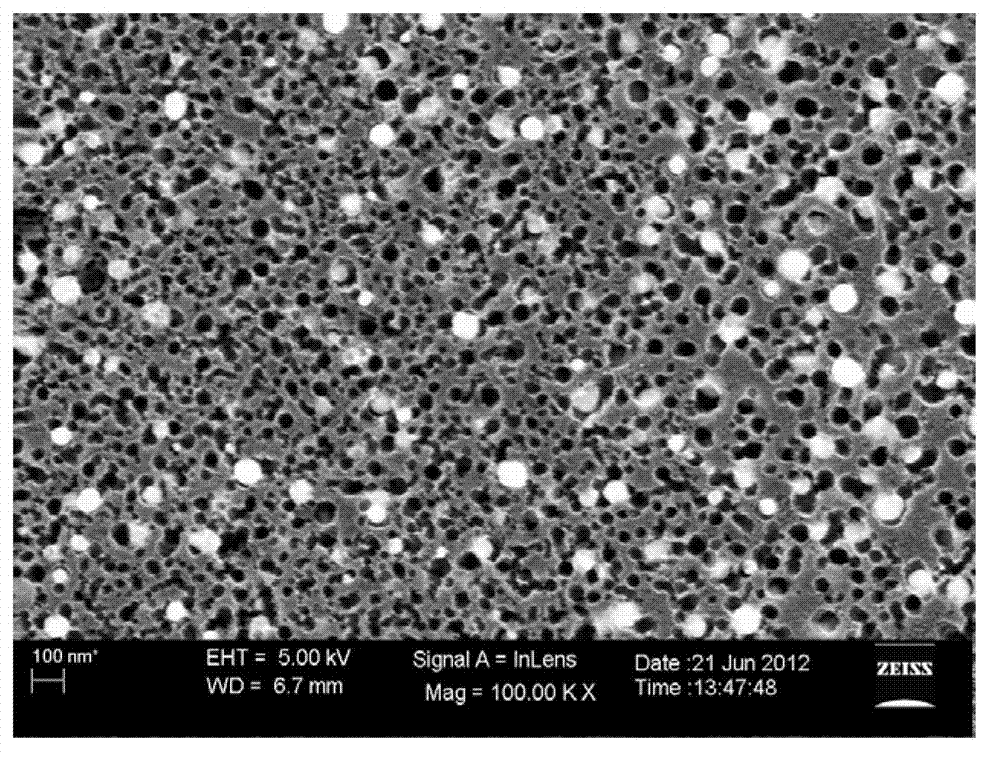

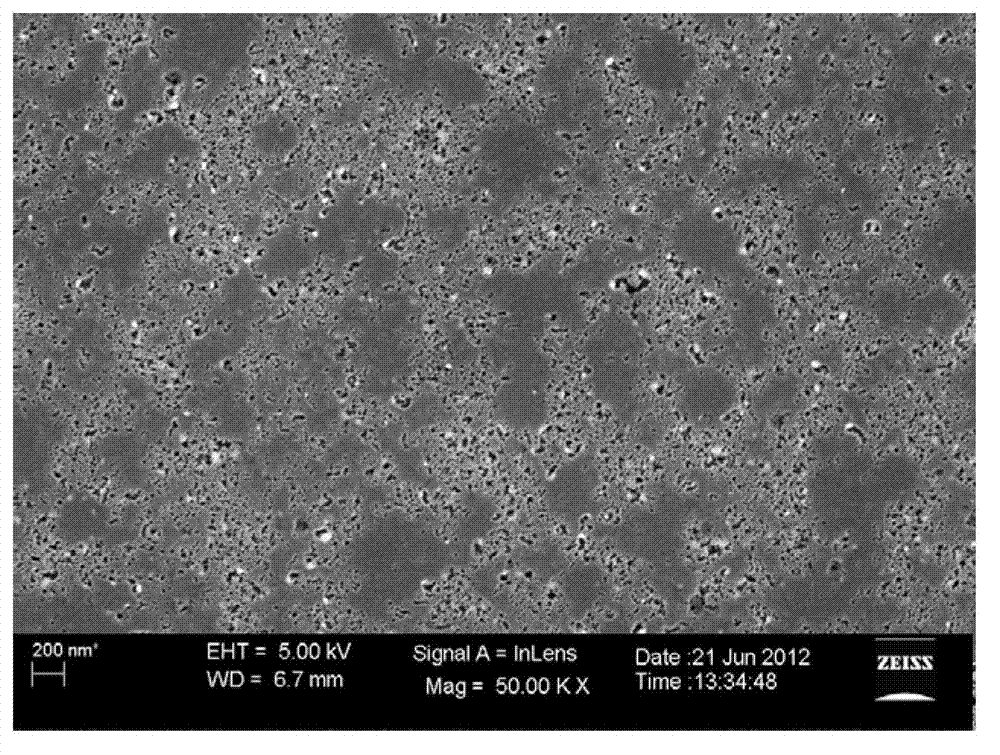

The invention discloses a preparation method of vinylidene chloride polymer base mesopore-micropore composite porous charcoal. The method comprises steps of: (1) adding a polyoxyethylene nonyl phenyl ether emulsifier in a nano silicon oxide aqueous dispersion, heating with stirring to reach adsorption balance and obtaining a modified nano silicon oxide aqueous dispersion; (2) adding the modified nano silicon oxide aqueous dispersion and an initiation system into a reaction kettle, heating, adding a mixture of vinylidene chloride and a second monomer and an anion emulsifier drop by drop, and carrying out in situ emulsion polymerization to obtain vinylidene chloride polymer / nano silicon oxide composite particles; (3) charring the vinylidene chloride polymer / nano silicon oxide composite particles at high temperature to obtain a charcoal / nano silicon oxide compound; (4) etching to remove nano silicon oxide in the charcoal / nano silicon oxide compound to prepare the mesopore-micropore composite porous charcoal. The porous charcoal prepared by the method of the invention has mesopore and micropore structures; the mesopores have narrow aperture distribution, large specific surfacearea and large pore volume. Therefore, the porous charcoal has promising application prospect in fields of new energy, environmental protection and industrial catalysis, etc.

Owner:ZHEJIANG UNIV

Process for producing vinyl chloride polymer

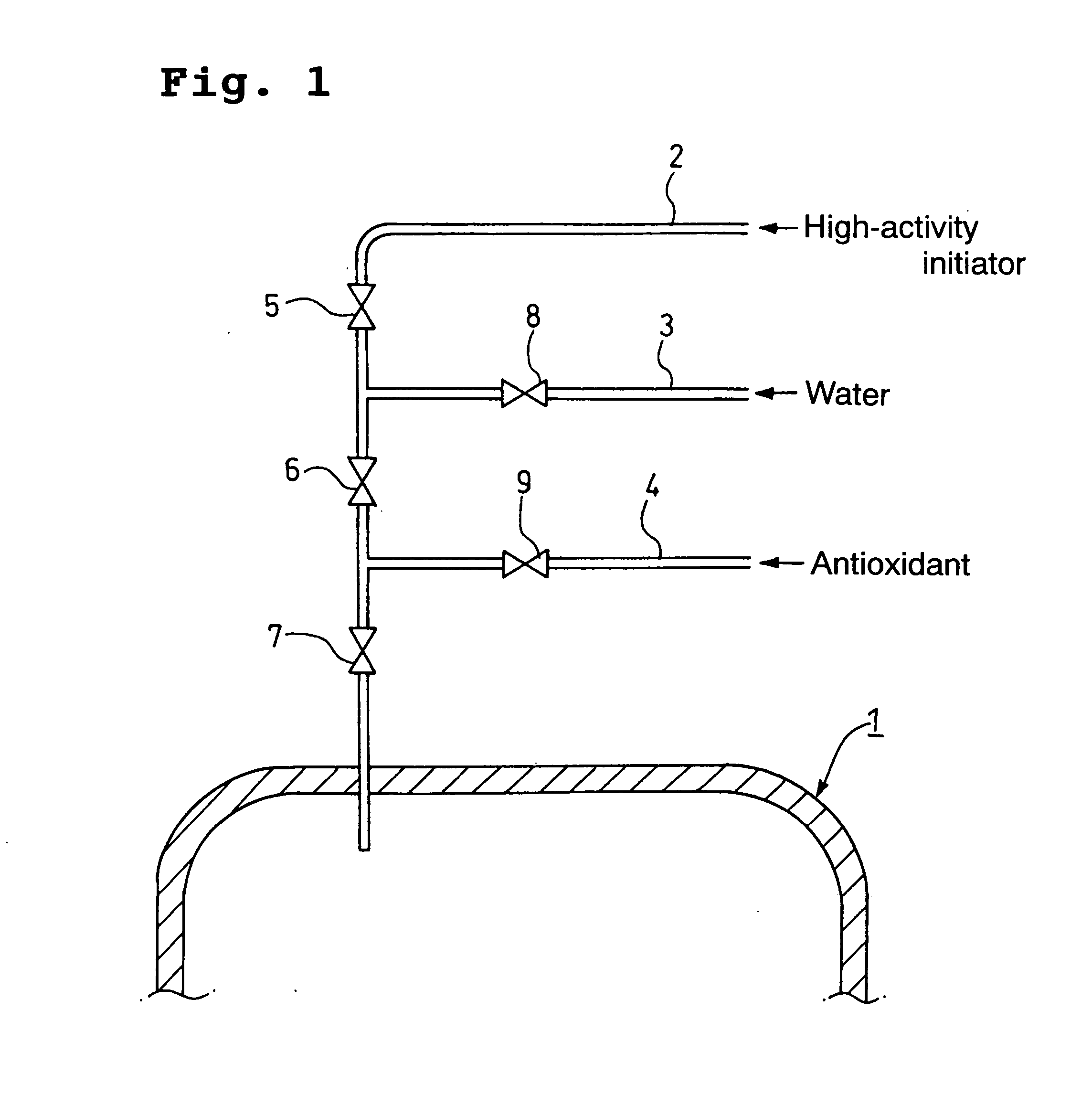

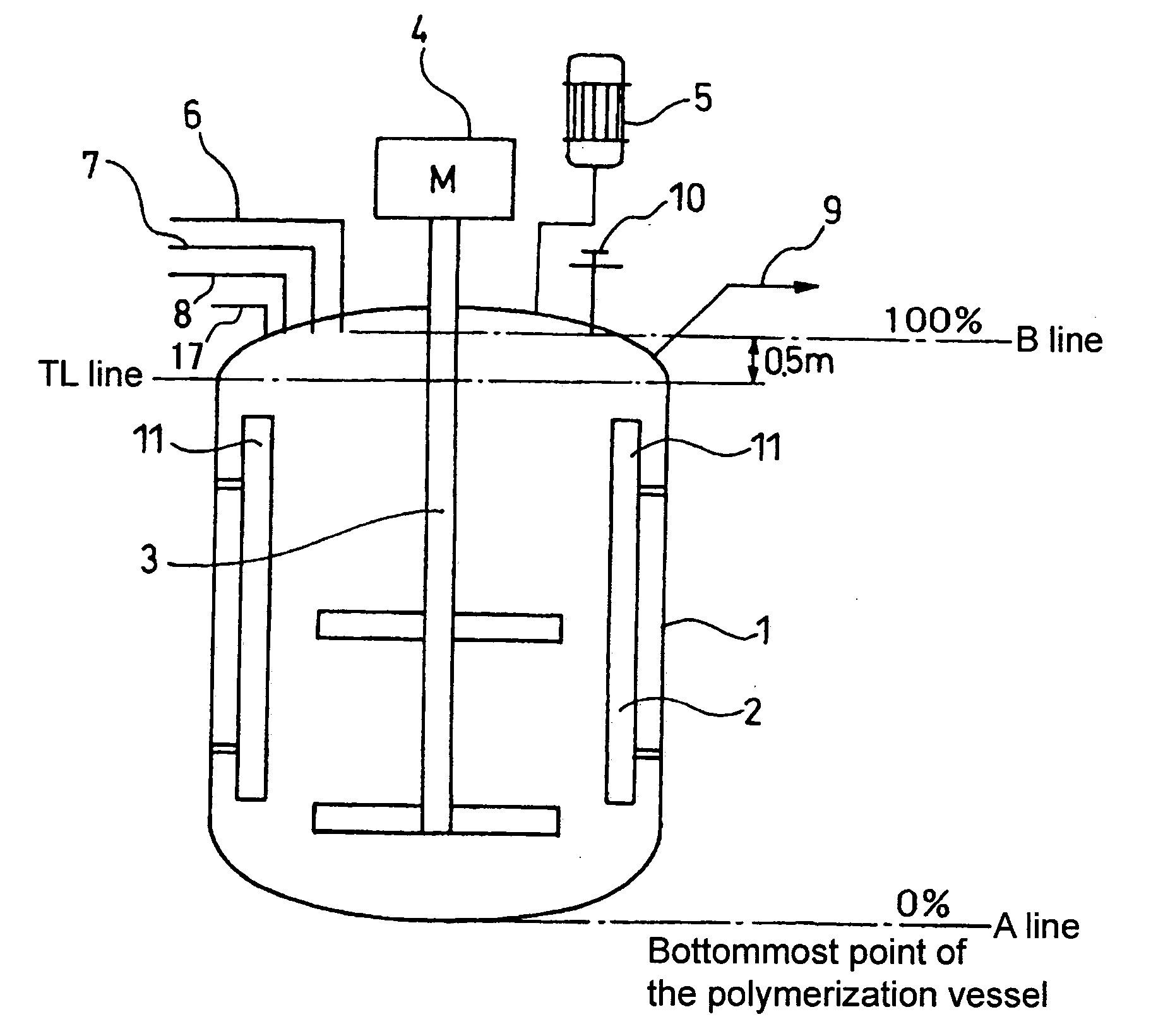

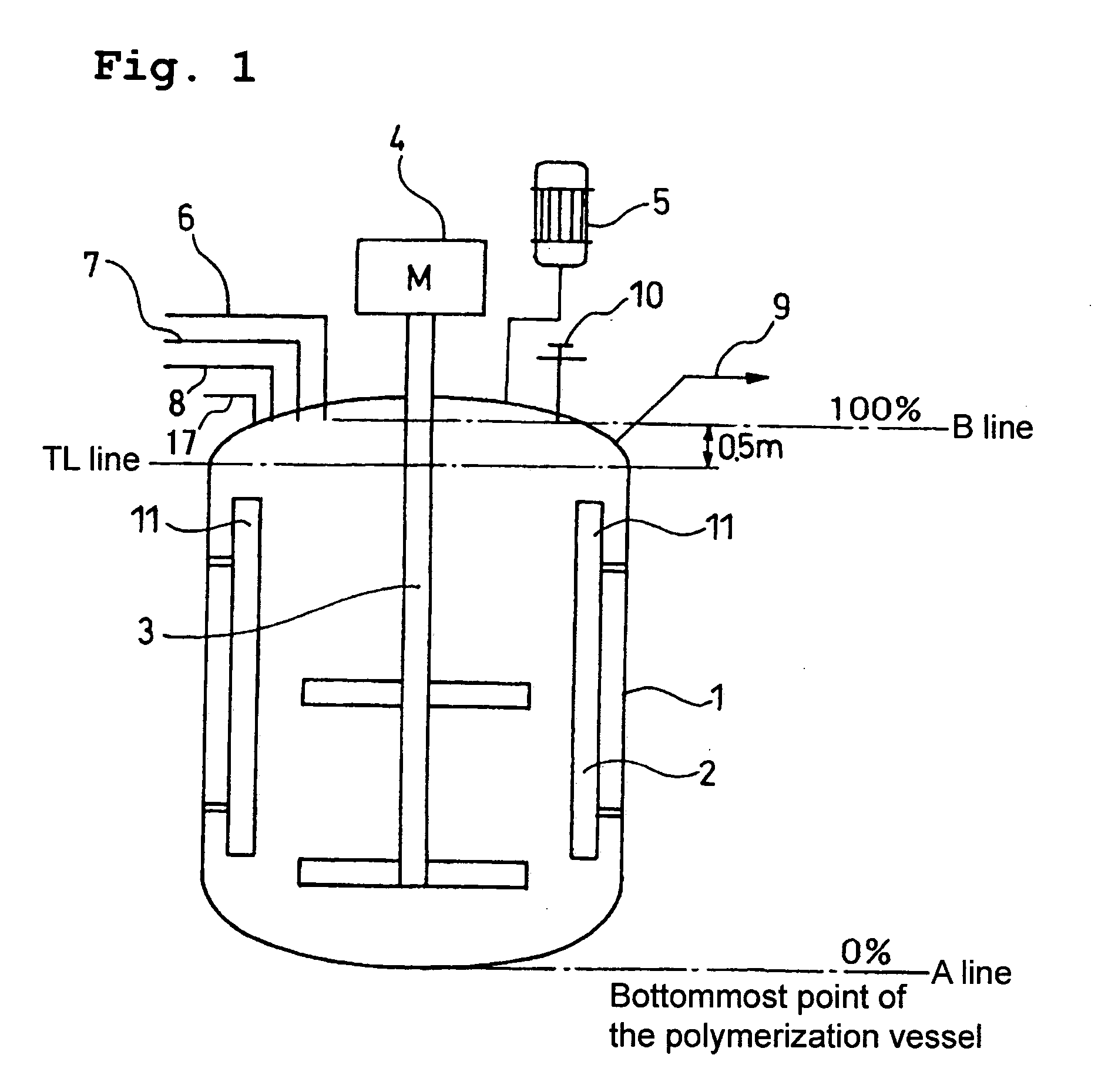

There is provided a process for producing a vinyl chloride-based polymer, in which a suspension polymerization of either vinyl chloride monomer, or a mixture of vinyl chloride monomer and another copolymerizable monomer, is conducted in a polymerization vessel fitted with a reflux condenser, the process including the steps of: (A) adding to the reaction mixture a high-activity, oil-soluble polymerization initiator, with a 10-hour half life temperature of no more than 40° C. at a concentration of 0.1 mol / L in benzene, for a specified time within a period from the commencement of heat removal using the reflux condenser through to completion of the polymerization, and (B) adding an antioxidant either continuously or intermittently to the reaction mixture at least during the period from the commencement of addition of the high-activity, oil-soluble polymerization initiator through to completion of that addition. According to the present invention, the process for producing a vinyl chloride-based polymer by aqueous suspension polymerization in a polymerization vessel fitted with a reflux condenser can be improved, the heat removal capability can be utilized effectively to shorten the polymerization time, and a high quality vinyl chloride-based polymer with an extremely low level of fish eyes can be produced.

Owner:SHIN ETSU CHEM IND CO LTD

Production process for vinyl chloride polymer

ActiveUS20050027088A1Accurately determineAccurate detectionLavatory sanitoryDisinfectionRefluxEthylene Polymers

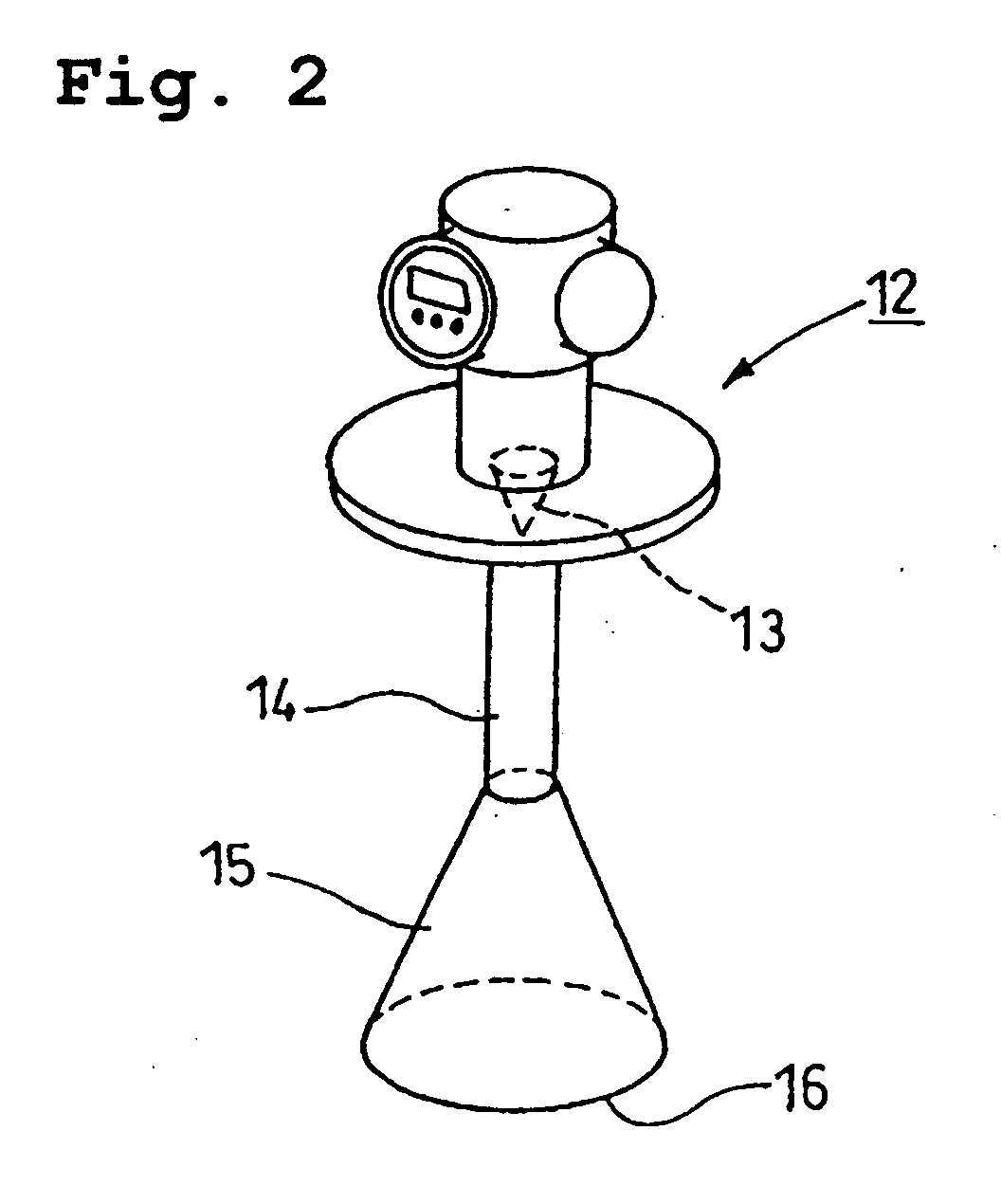

A production process for a vinyl chloride polymer is proposed in which either vinyl chloride, or a monomer mixture comprising vinyl chloride, is polymerized in an aqueous medium inside a polymerization vessel, while heat removal is conducted using a reflux condenser. In this process, the liquid level of the contents inside the polymerization vessel is monitored using an electric wave liquid level gauge, which is disposed on the polymerization vessel and radiates microwaves with a frequency of 4 to 20 GHz. The operating efficiency of the reflux condenser can be improved, and the quantity of heat removed by the reflux condenser can be increased. Furthermore, the time required to complete the process, including the raw material addition step and / or the washing step conducted following completion of the polymerization, can be shortened.

Owner:SHIN ETSU CHEM IND CO LTD

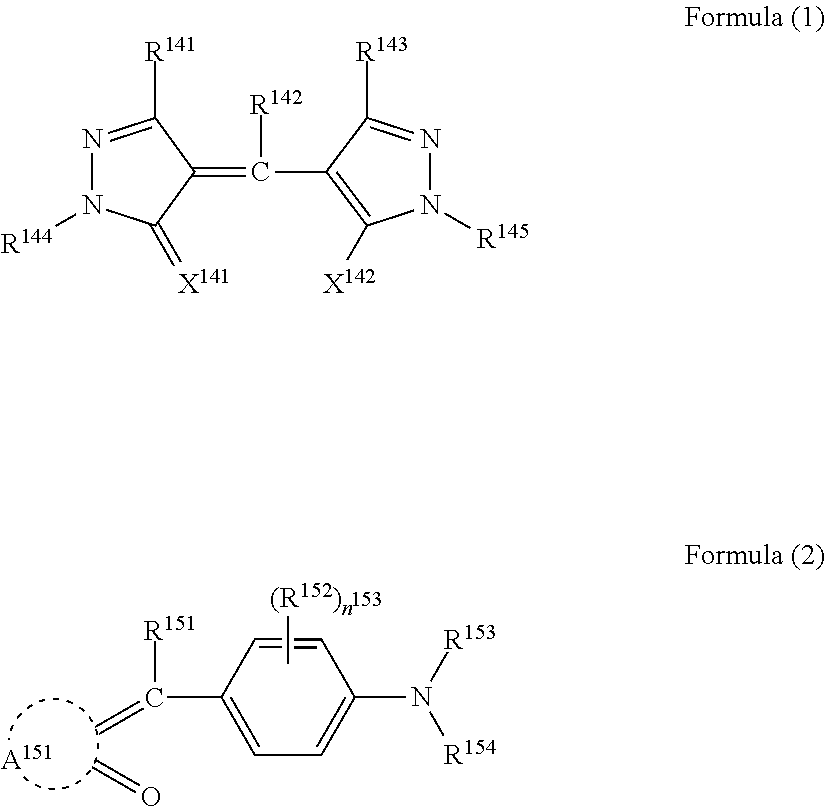

Image-forming method using heat-sensitive transfer system

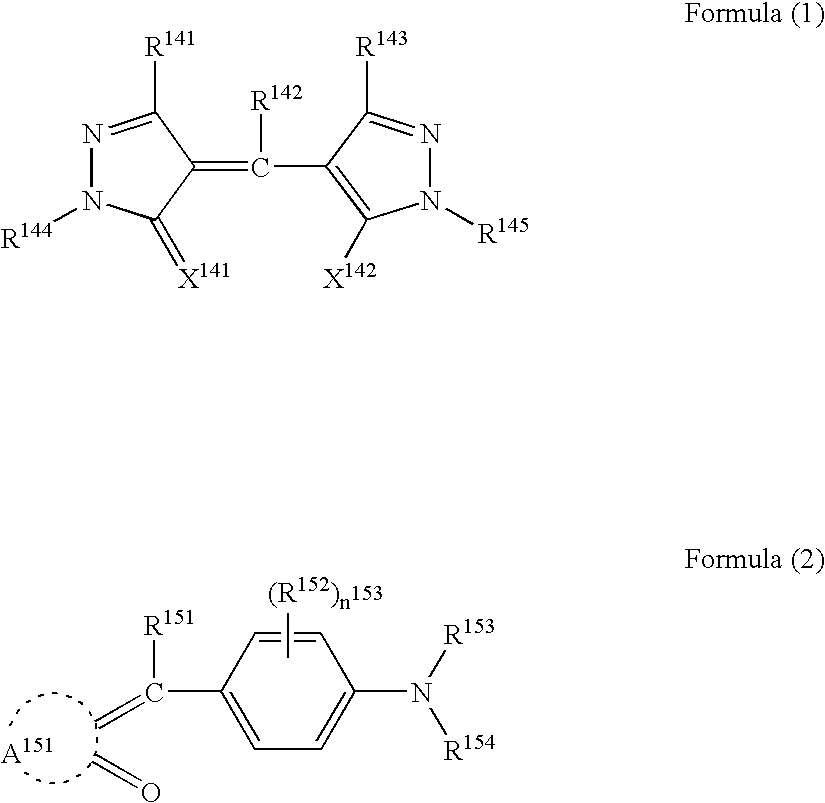

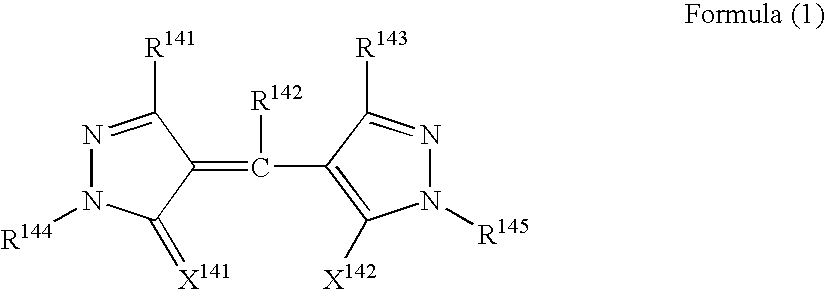

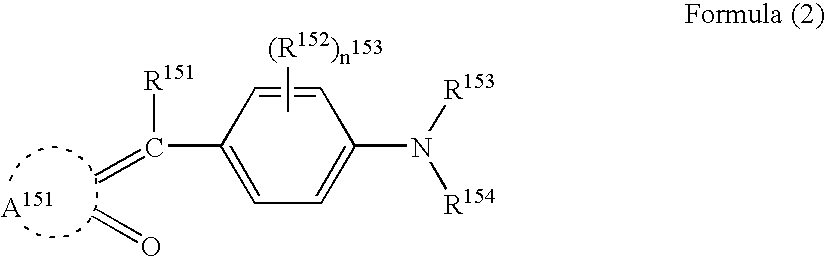

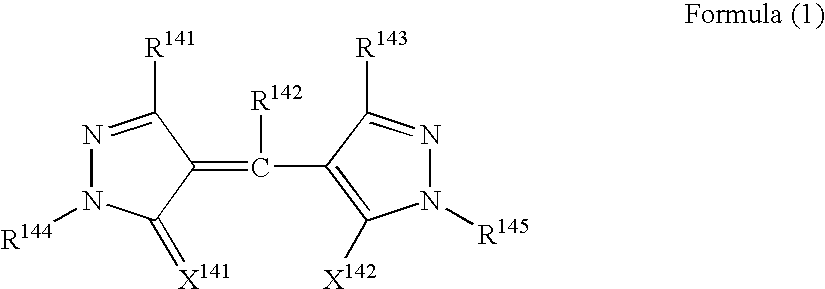

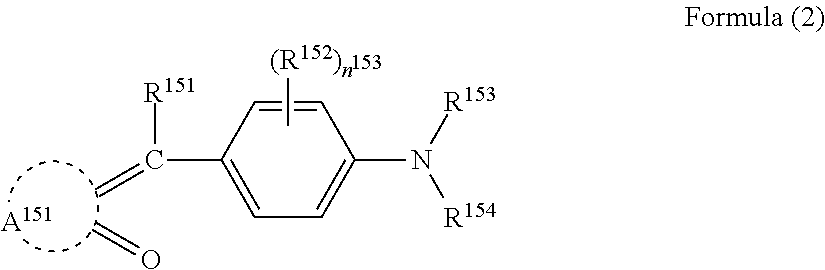

An image-forming method: by superposing a heat-sensitive transfer sheet on a heat-sensitive transfer image-receiving sheet so that a receptor layer can be contacted with a thermal transfer layer; and providing thermal energy in accordance with image signals; in which the heat-sensitive transfer image-receiving sheet comprises the receptor layer containing one of polyester and / or polycarbonate polymers, vinyl chloride polymers and / or a polymer latex; and in which the heat-sensitive transfer sheet comprises the thermal transfer layer containing a dye represented by formula (1) or (2): wherein, X141 represents an oxygen atom, a sulfur atom, or NR146; X142 represents a hydroxyl group, a mercapto group, or NHR147; R141 to R154 each represent a hydrogen atom or a substituent; A151 represents a group of atoms necessary to form a hetero ring together with the two carbon atoms; and n153 represents an integer of 0 to 4.

Owner:FUJIFILM CORP

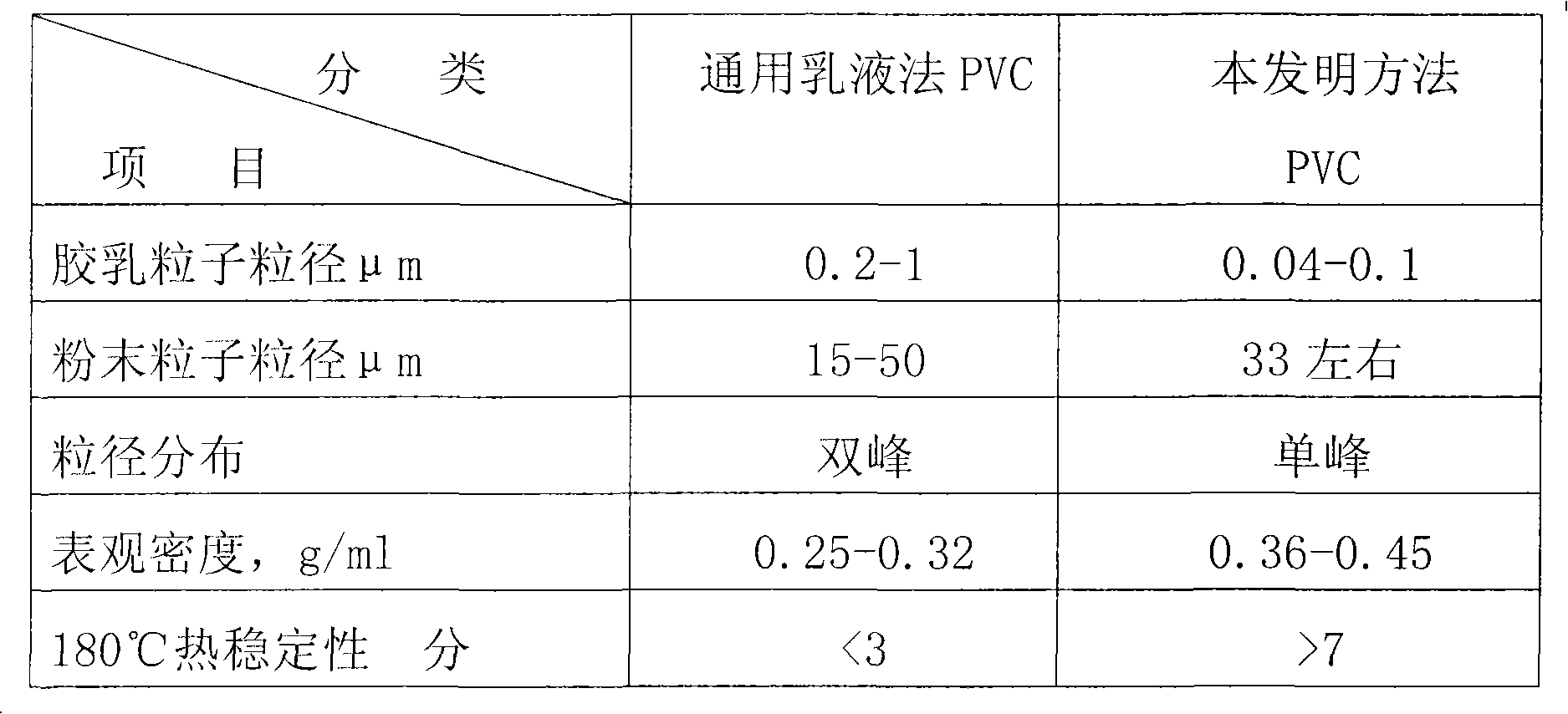

Production method for polyvinyl chloride powder for preparing baffle plate of lead acid storage battery

InactiveCN101851309AProper molecular weightProper Molecular Weight DistributionCell component detailsProcess optimizationEmulsion polymerization

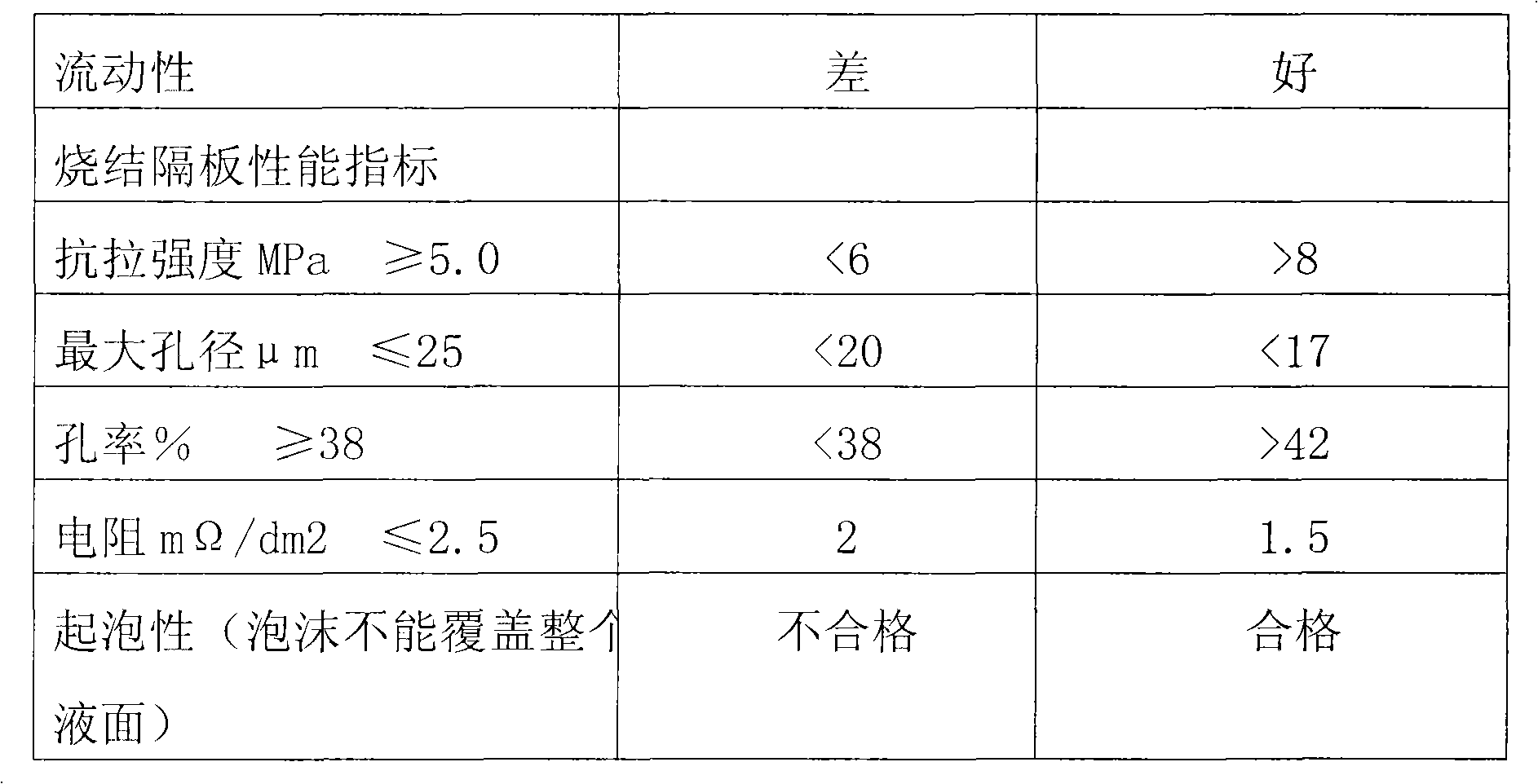

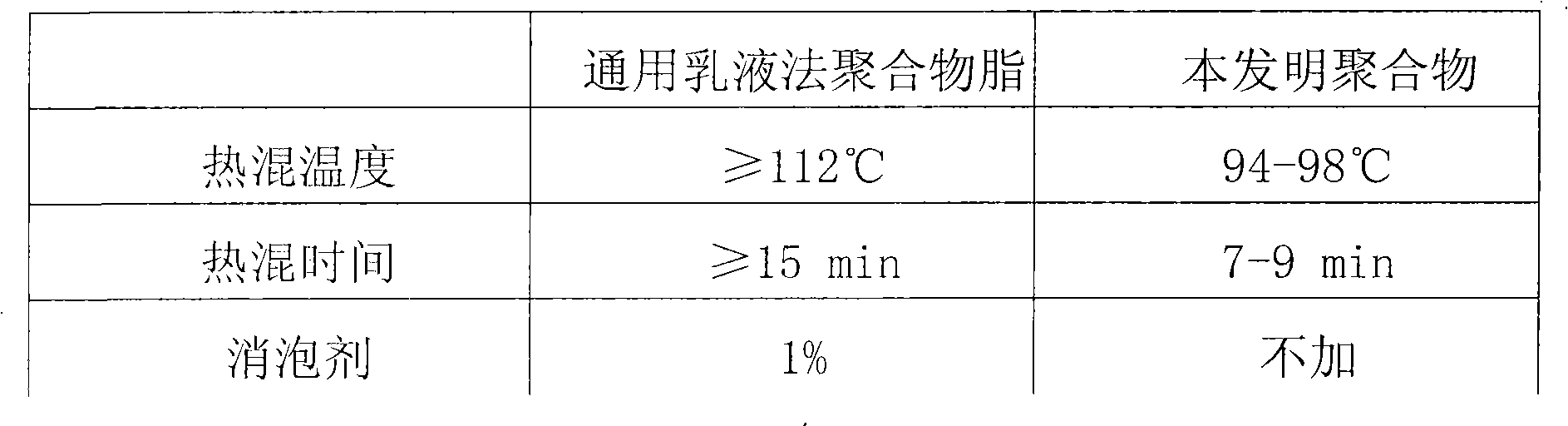

The invention discloses a production method for polyvinyl chloride powder for preparing a baffle plate of a lead acid storage battery, and belongs to the field of the emulsion polymerization method of a vinyl chloride monomer. The method comprises the following steps of: adding the component materials such as the vinyl chloride monomer, an initiator, an emulsifier, a pH regulator, desalted water and the like into a polymerization kettle in proportion and performing polymerization on the materials to produce a latex polymer by using the emulsion polymerization method; adding an after-treating agent to process the latex polymer; and performing spray drying on the mixture to obtain the polyvinyl chloride powder, of which 80 percent has the particle diameter of about 33 mu m so as to ensure that the polymer has proper molecular weight and molecular weight distribution, stable molecular structure, superior powder flowability and high thermal stability. The method solves the problems of the conventional polyvinyl used for producing the baffle plate of the storage battery through the set formula for the materials of the polymerization and process optimization, so the method completely meets the requirement of the standard for producing the polyvinyl chloride powder for the baffle plate of the storage battery and provides the high-quality polyvinyl chloride powder which meets the national standard for the production of the baffle plate of the storage battery.

Owner:武汉祥龙电业股份有限公司

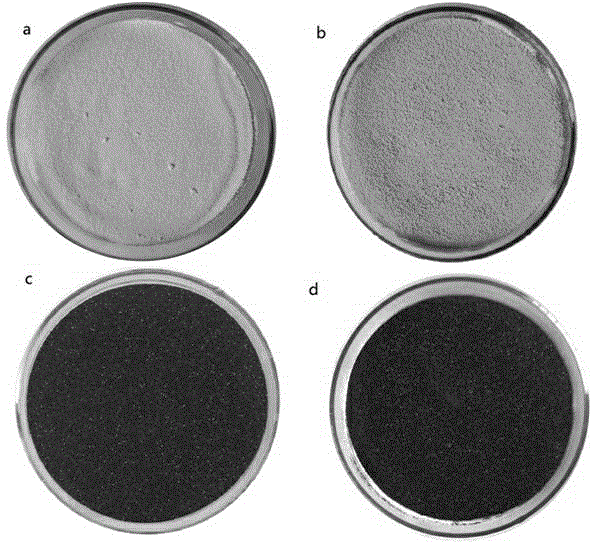

Preparation method of vinyl chloride polymer ionic liquid porous membrane

InactiveCN104607059ANot easy to loseImprove stabilitySemi-permeable membranesPolyvinyl chloridePorous membrane

The invention discloses a preparation method of a vinyl chloride polymer ionic liquid porous membrane. The preparation method comprises the following steps: preparing vinyl chloride polymer ionic liquid (PVC-mimX), and then preparing the vinyl chloride polymer ionic liquid porous membrane by adopting an immersion precipitation phase inversion process. According to the preparation method of the vinyl chloride polymer ionic liquid porous membrane, the process is simple, raw materials are easily available, the reaction time is short, the reaction condition is mild, no expense instrument is required, the industrial implementation can be realized easily, the prepared vinyl chloride polymer ionic liquid porous membrane has the good antifouling property, good physical properties of a polyvinyl chloride membrane are kept, and the vinyl chloride polymer ionic liquid porous membrane has good stability and has the high-efficiency separation characteristic.

Owner:FUZHOU UNIV

Rigid polyvinyl chloride polymer compositions having improved impact properties

Rigid polyvinyl chloride compositions are disclosed that are suitable for use in applications such as window profiles, door frames, siding, fences, gutters, pipes, electrical junction boxes, automobile interiors and exteriors, appliances, office equipment or medical devices. The disclosed compositions include polyvinyl chloride polymers or copolymers having incorporated therein 2,2,4-trimethyl-1,3-pentanediol diisobutyrate in amounts so as to improve the impact properties of the compositions. Processes for making such compositions are also disclosed.

Owner:EASTMAN CHEM CO

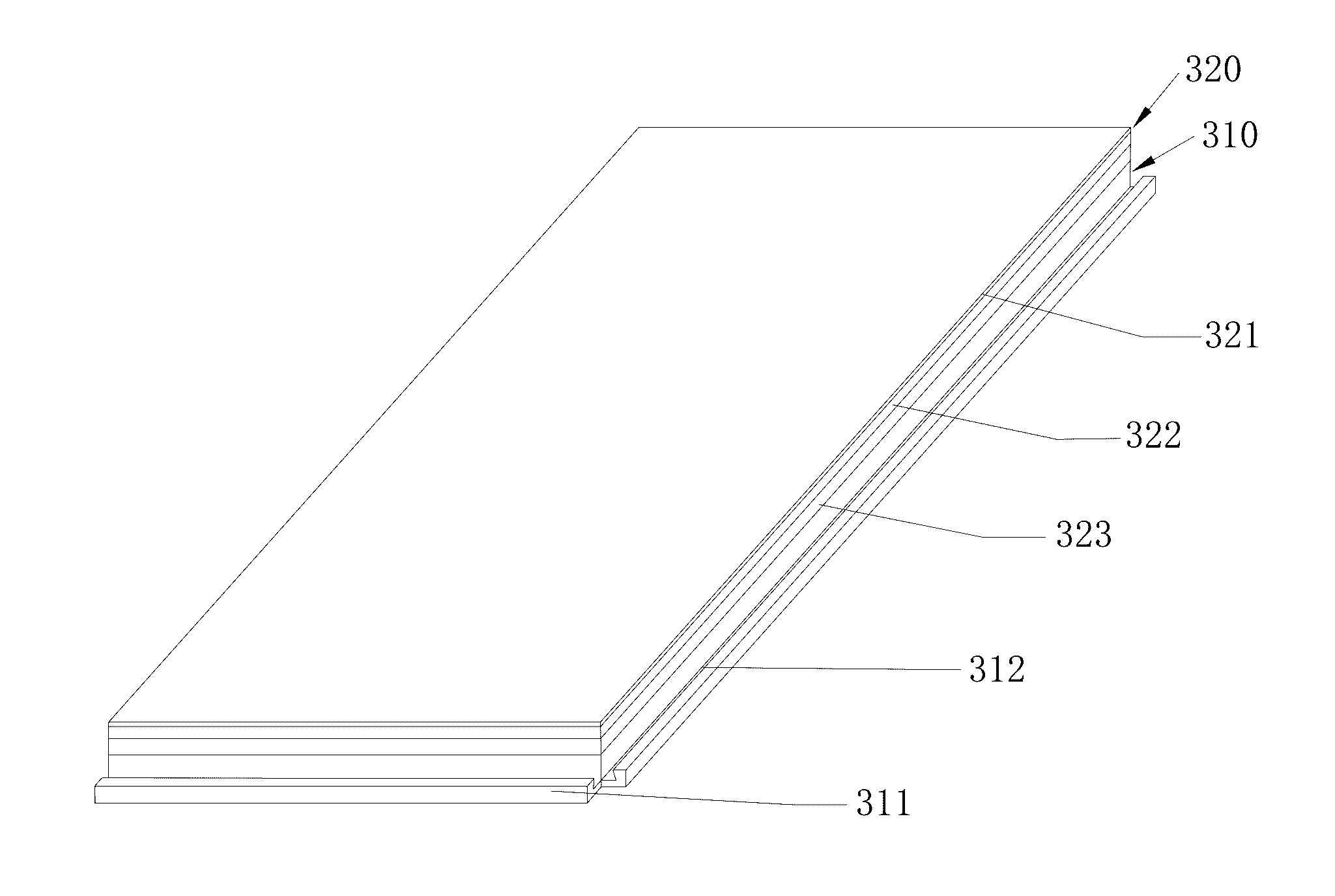

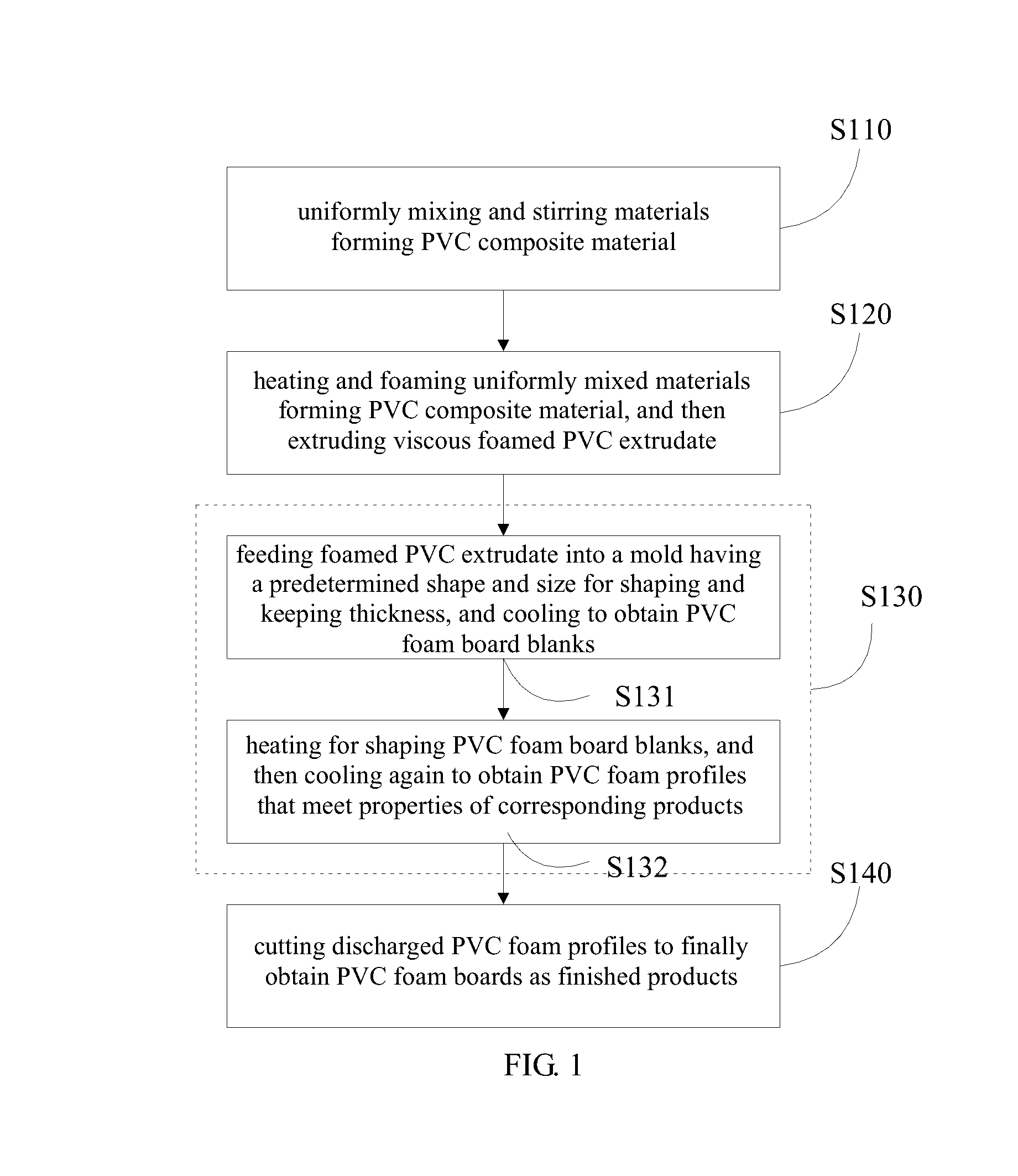

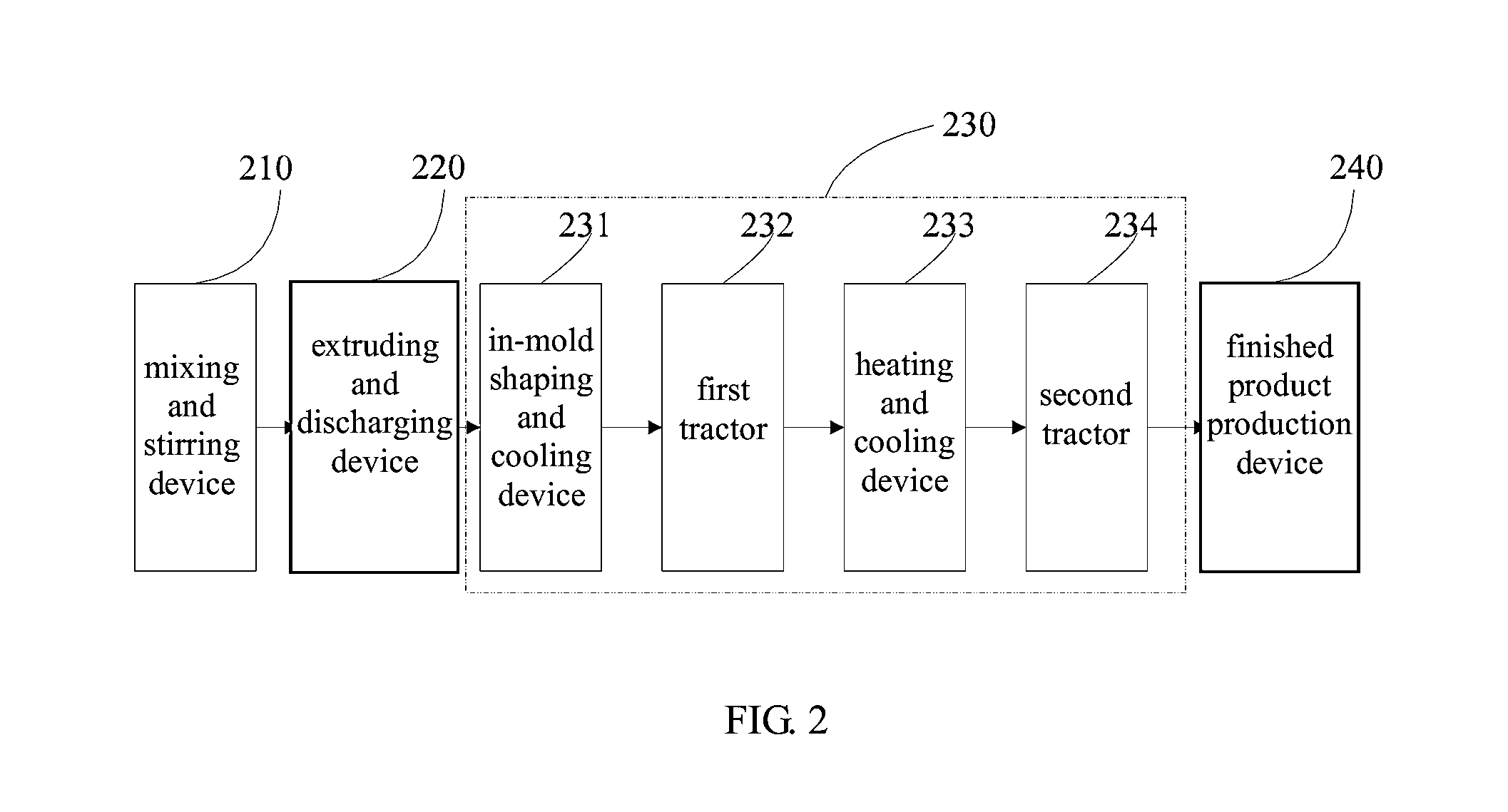

PVC composite material, foam board, production method and apparatus thereof, and flooring

ActiveUS9527975B2Quality improvementImprove propertiesSynthetic resin layered productsConstructions elementsFoaming agentPolyvinyl chloride

The present invention provides a polyvinyl chloride polymer (PVC) composite material including 40-60 parts by weight of PVC, 40-60 parts by weight of light calcium carbonate, 0.8-1.2 parts by weight of composite foaming agent including an inorganic foaming agent and an organic foaming agent, 3-5 parts by weight of foam regulator, 2-4 parts by weight of toughener, 0.8-1.2 parts by weight of lubricant, and 1.5-2.5 parts by weight of stabilizer. The ratio of the inorganic foaming agent to the organic foaming agent by weight in the composite foaming agent is ½-1. Meanwhile, the present invention provides a foam board made of the PVC composite material, an associated production method, an apparatus, and flooring. The resulting PVC products have a high-strength structure and a good foaming property, thus having a satisfied mute effect.

Owner:FLOORING IND LTD

Image-forming method using heat-sensitive transfer system

An image-forming method: by superposing a heat-sensitive transfer sheet on a heat-sensitive transfer image-receiving sheet so that a receptor layer can be contacted with a thermal transfer layer; and providing thermal energy in accordance with image signals;in which the heat-sensitive transfer image-receiving sheet comprises the receptor layer containing one of polyester and / or polycarbonate polymers, vinyl chloride polymers and / or a polymer latex; andin which the heat-sensitive transfer sheet comprises the thermal transfer layer containing a dye represented by formula (1) or (2):wherein, X141 represents an oxygen atom, a sulfur atom, or NR146; X142 represents a hydroxyl group, a mercapto group, or NHR147; R141 to R154 each represent a hydrogen atom or a substituent; A151 represents a group of atoms necessary to form a hetero ring together with the two carbon atoms; and n153 represents an integer of 0 to 4.

Owner:FUJIFILM CORP

Transparent Chlorinated Polyethylene Thermoplastic

The invention relates to the technical field of plastic products, in particular to a transparent chlorinated polyethylene thermoplastic material. The technical scheme is that: the transparent chlorinated polyethylene thermoplastic material consists of 80 to 95 mass percent of chloroethylene polymer and 5 to 20 mass percent of chlorinated polyethylene, wherein the chlorinated polyethylene consistsof two kinds of high density chlorinated polyethylene B1 and B2 with different parameters; the high density chlorinated polyethylene B1 accounts for 2.5 to 10 percent of the total mass of the material, and has the chlorine content of 37-42 percent, the residual value of 0-30 percent and the swell value of 10-70 percent; and the high density chlorinated polyethylene B2 accounts for 2.5 to 10 percent of the total mass of the material, and has the chlorine content of 37-42 percent, the residual value of 50-70 percent and the swell value of 1-2 percent. The chlorinated polyethylene has simple components; the preparation method is simple, convenient and low in cost; and the thermoplastic material prepared from the chlorinated polyethylene has good toughness and transparency and good light fastness and weather change resistance.

Owner:山东旭业新材料有限公司

Heat-sensitive transfer image-receiving sheet

A heat-sensitive transfer image-receiving sheet, containing, on a support, a receptor layer containing at least one of vinyl chloride polymers, and an intermediate layer containing hollow polymer particles between the support and the receptor layer.

Owner:FUJIFILM CORP

Method for preparing mesopore-micropore composite porous carbon on basis of vinylidene chloride polymers

ActiveCN102807206AEasy to prepareImprove correspondenceCarbon preparation/purificationPorous carbonPolyethylene glycol

The invention discloses a method for preparing mesopore-micropore composite porous carbon on the basis of vinylidene chloride. The method includes steps of 1), adding 1,4-dioxane, vinylidene chloride, polyethylene-glycol-based macromolecular RAFT (reversible addition-fragmentation transfer) reagents and azodiisobutyronitrile into a reaction kettle, stirring the reactants at the room temperature to dissolve and mix the reactants together, charging nitrogen, removing oxygen, heating the mixture, enabling the reactants to have polymerization reaction to generate reaction liquid, adding precipitating agents into the reaction liquid, depositing the reaction liquid to obtain deposits, separating the deposits and drying the separated deposits to obtain segmented copolymers comprising vinylidene chloride polymers (copolymers) and polyethylene glycol; and 2), placing the segmented copolymers into a crucible, placing the crucible in a high-temperature furnace, heating the high-temperature furnace, keeping the temperature of the high-temperature furnace constant, and then slowly reducing the temperature of the high-temperature furnace to reach the constant temperature so as to obtain the mesopore-micropore composite porous carbon. The method is simple, a synthetic carbon precursor structure effectively corresponds to a porous carbon material structure, and the mesopore-micropore composite porous carbon has a mesopore-micropore aperture structure with narrow aperture distribution, and has a good application prospect in fields such as electrodes of super-capacitors, gas adsorption and industrial catalysis.

Owner:ZHEJIANG UNIV

Vinyl chloride polymer composition

The present invention provides a vinyl chloride polymer composition which comprises (i) a vinyl chloride polymer (a) and (ii) a block copolymer (b) having a polymer block (I) comprising of a block copolymer, which may be hydrogenated, of an aromatic vinyl compound polymer block and a conjugated diene polymer block, and a polymer block (II) of a polyurethane, in a specific weight ratio. The vinyl chloride polymer composition of the present invention has non-tackiness, excellent handling properties, favorable flexibility and mechanical properties, and favorable melt-adhesiveness to other materials, and shows no migration of the component serving as a plasticizer. The vinyl chloride polymer composition of the present invention can be applied for various uses such as a production of various molded articles and a production of a laminated structure with other materials.

Owner:KURARAY CO LTD

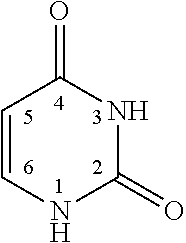

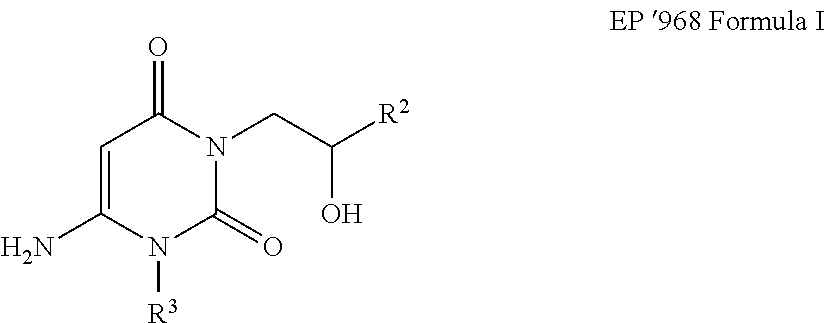

Novel coupled uracil compound for vinyl chloride polymer resins

InactiveUS20170313855A1Effective and stableReadily availableOrganic chemistryRigid pipesHalogenPolymer resin

The disclosed technology relates to a novel coupled 6-amino uracil derivative, and the use of the coupled 6-amino uracil derivative as a stabilizer in halogen containing polymer compounds. In particular, the disclosed technology relates to the use of a coupled 6-amino uracil derivative as a stabilizer in vinyl chloride compounds, such as, for example, chlorinated polyvinyl chloride (CPVC) compounds.

Owner:LUBRIZOL ADVANCED MATERIALS INC

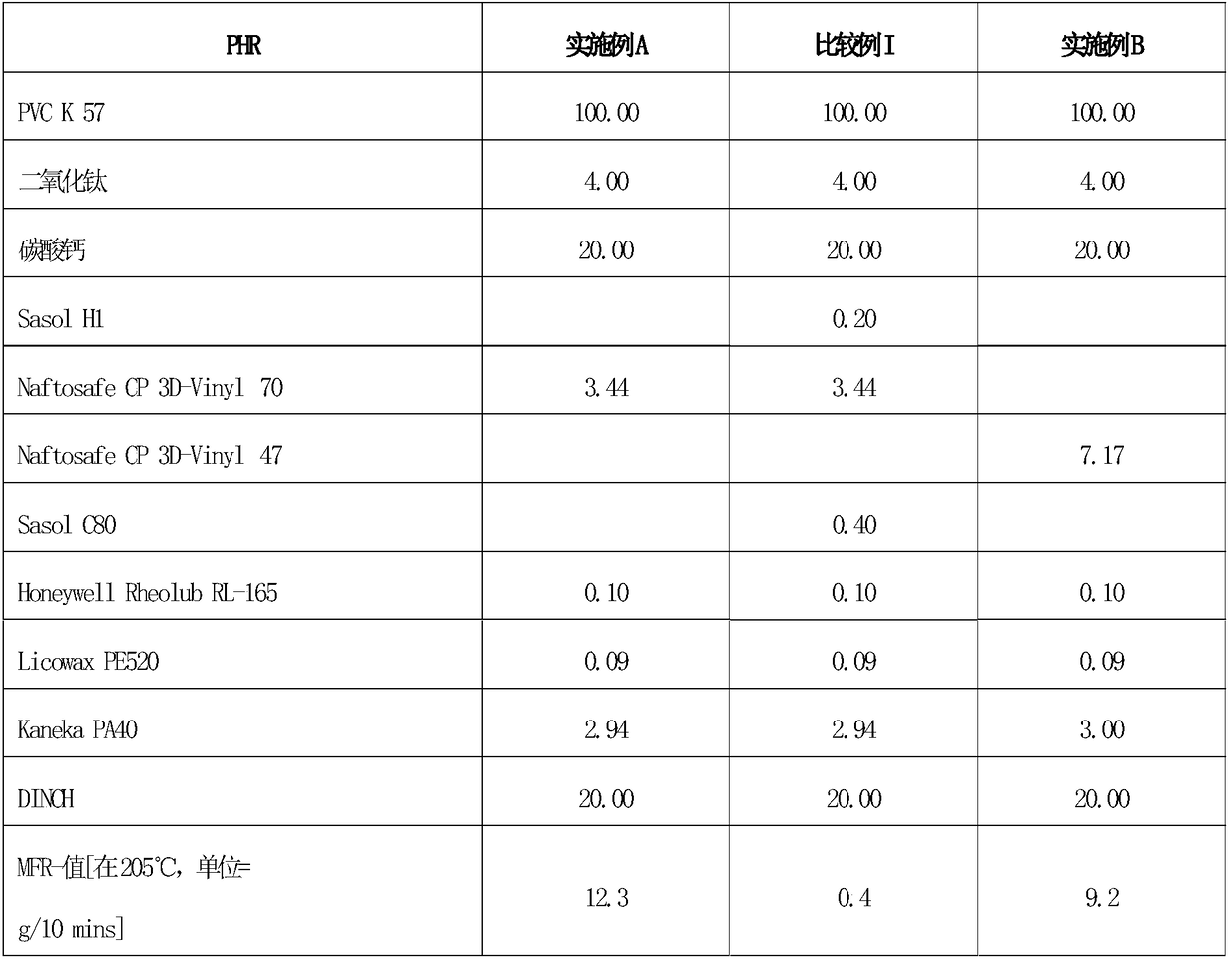

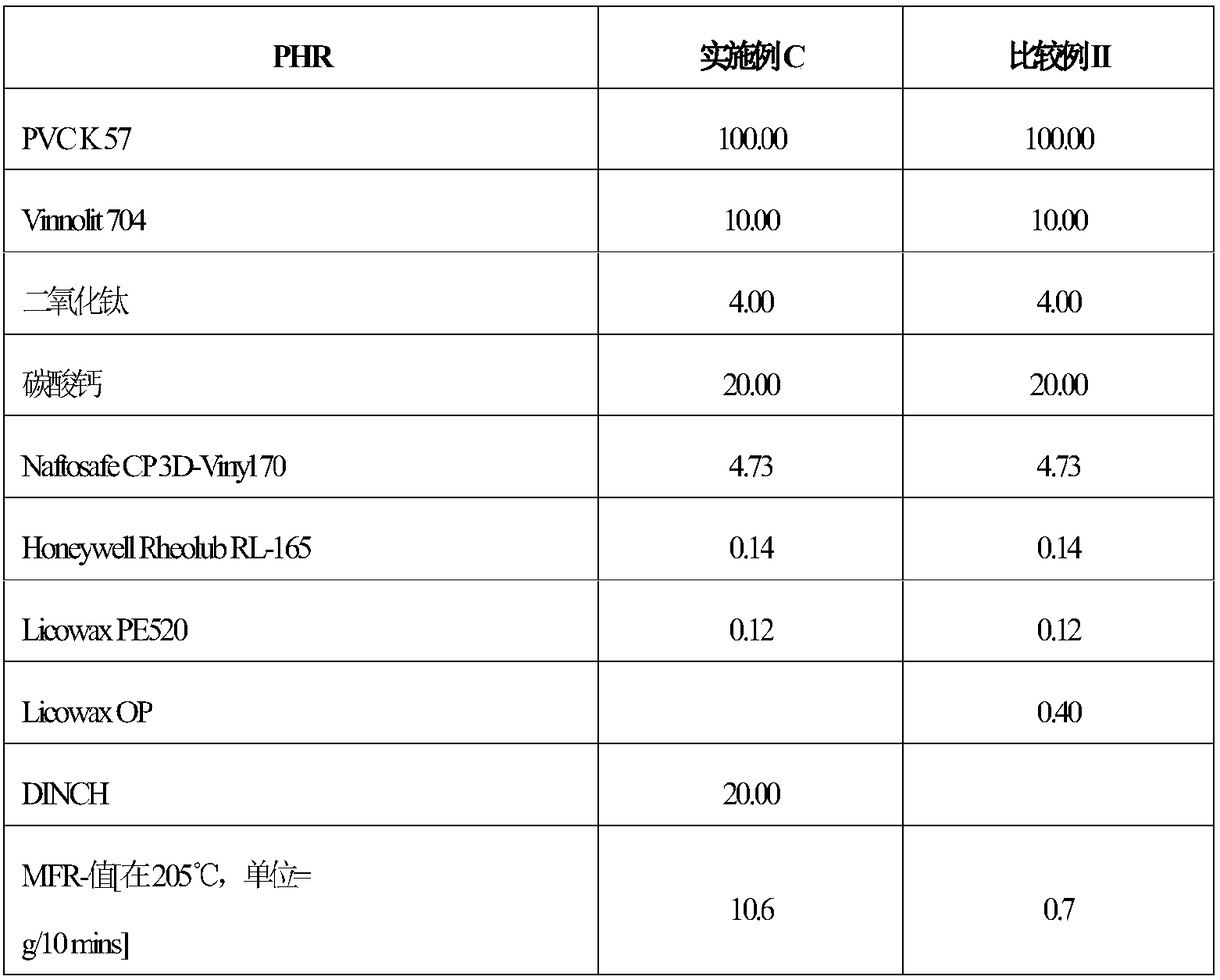

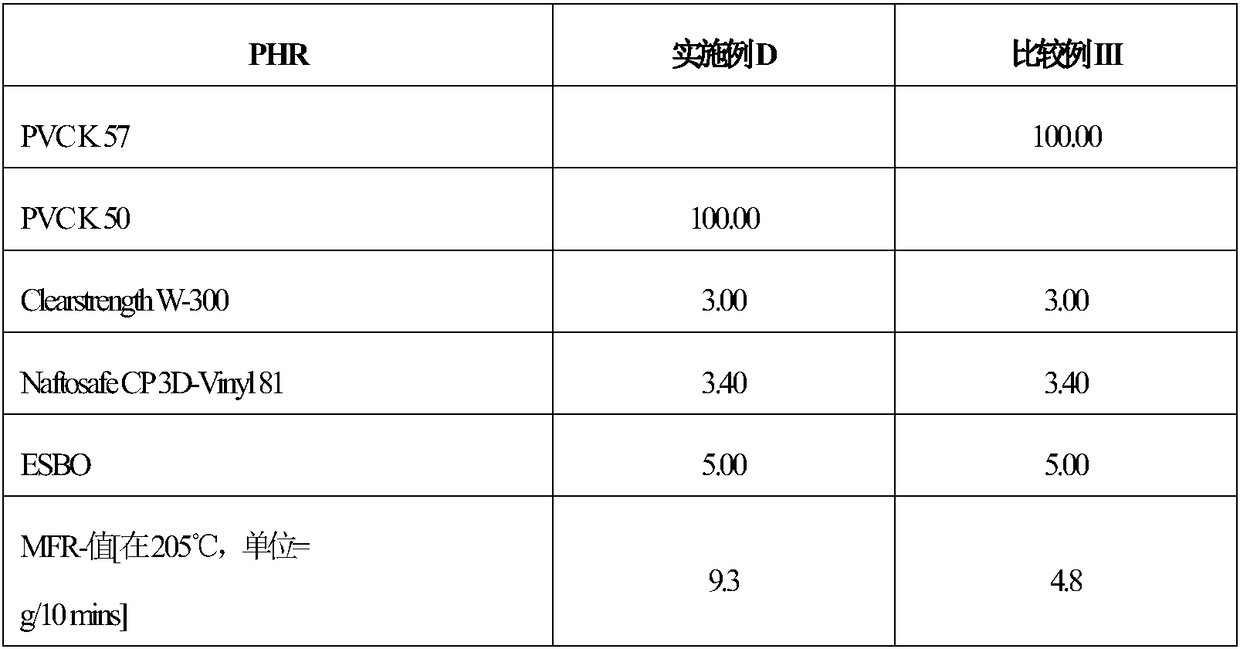

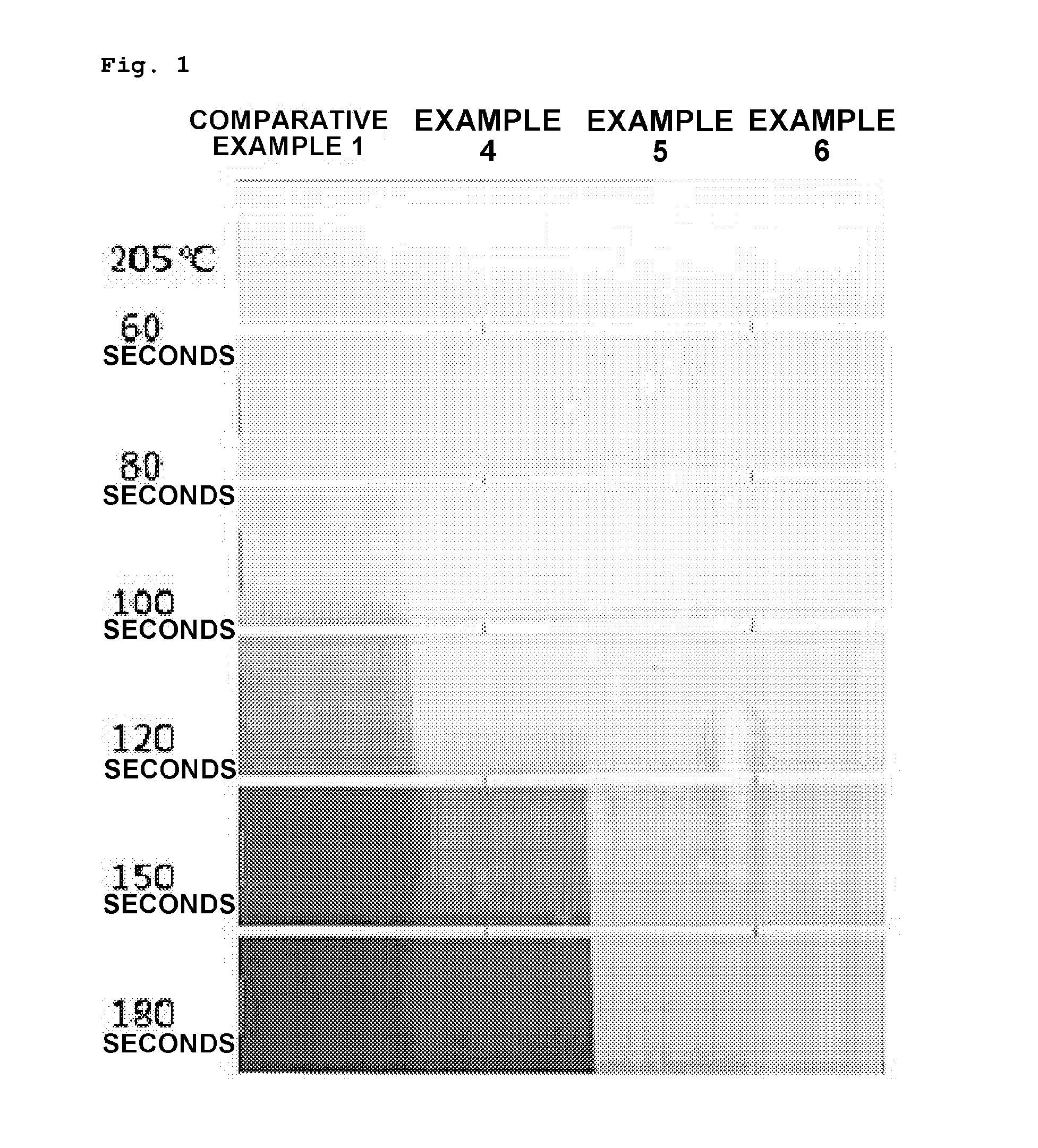

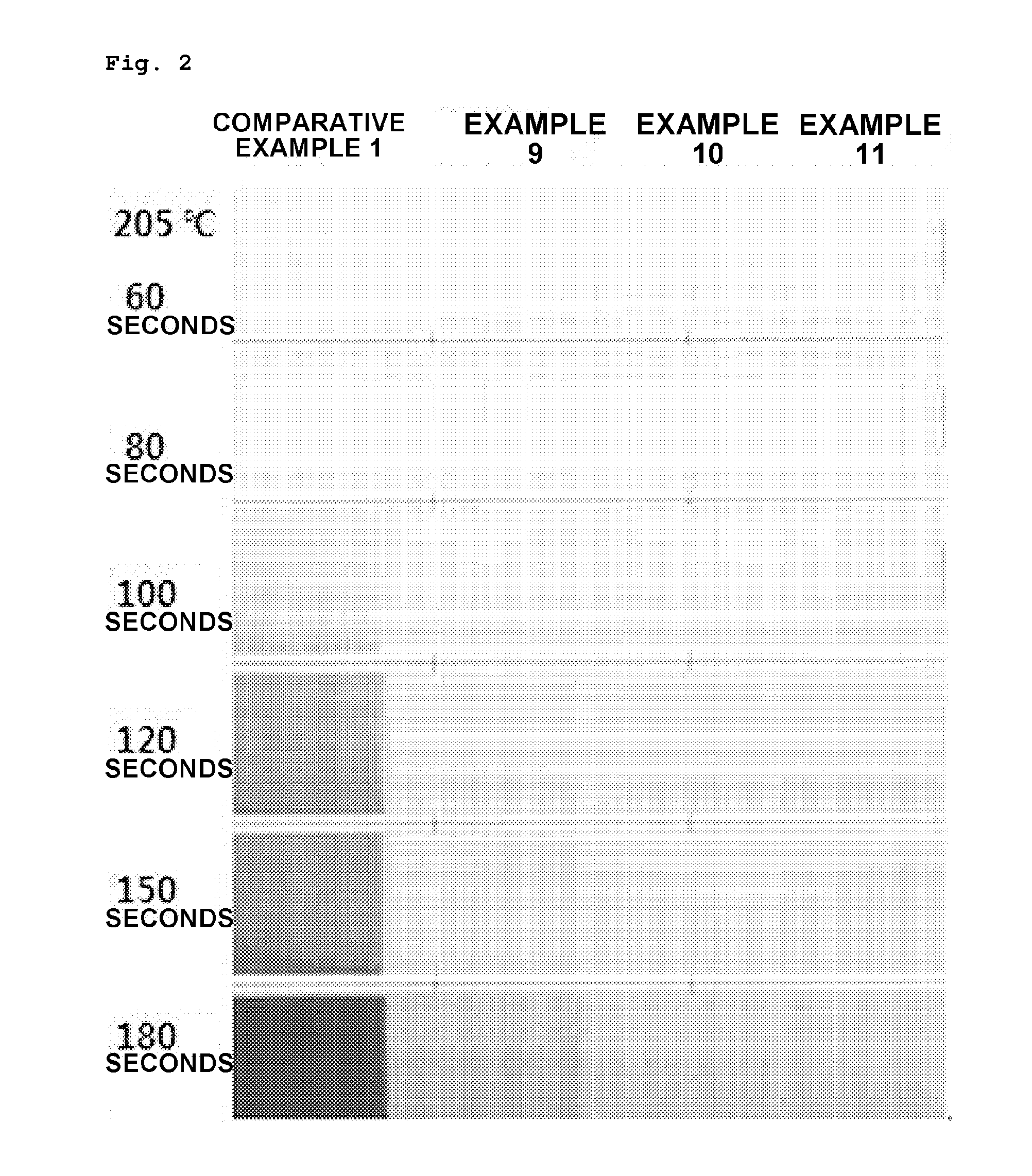

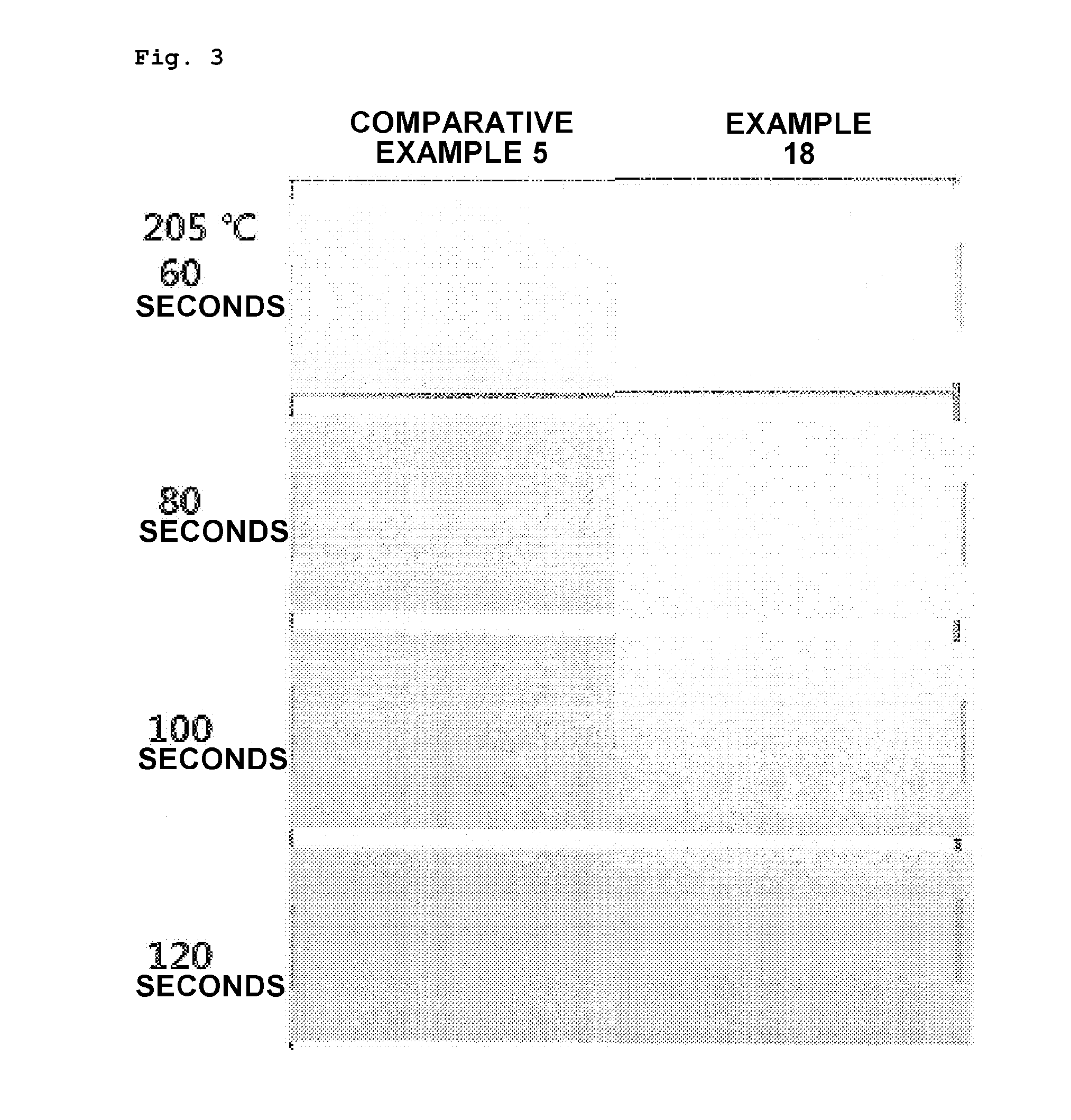

Vinyl chloride polymers and compositions for additive manufacturing

PendingCN108350116AAdditive manufacturing apparatusAdditive manufacturing with liquidsPolymer scienceVinylchloride polymer

The present disclosure is directed to a thermoplastic polymer for additive manufacturing, wherein the thermoplastic polymer is derived from a chlorinated monomer unit, wherein the thermoplastic polymer has a melt flow rate (MFR) suitable for additive manufacturing. The present disclosure is also directed to a method of making a 3D product formed by additive manufacturing, wherein the 3D product comprises a thermoplastic polymer derived from a chlorinated monomer unit or a thermoplastic composition comprising at least one thermoplastic polymer derived from a chlorinated monomer unit; and at least one stabiliser, wherein the thermoplastic polymer or composition has a MFR suitable for additive manufacturing.

Owner:CHEMSON POLYMER ADDITIVE AG

Preparation method of vinyl chloride polymer and vinyl chloride polymer prepared thereby

ActiveUS20160369018A1Avoid it happening againLow generation degreePolymer scienceVinylchloride polymer

The present invention relates to a method of preparing a vinyl chloride polymer having good thermal stability by restraining a dehydrochlorination reaction due to heat or ultraviolet rays, and a vinyl chloride polymer prepared thereby. According to the preparation method, the adding point of a modifier is controlled, and a vinyl chloride polymer markedly restraining the generation of dehydrochloric acid due to heat or ultraviolet rays may be prepared. Therefore, the preparation method of the vinyl chloride polymer via the emulsion polymerization and the vinyl chloride polymer prepared thereby in the present invention may be readily applied to industries requiring the vinyl chloride polymer such as industries concerning a vinyl chloride resin and a molded article.

Owner:LG CHEM LTD

Vinyl chloride polymer and preparation method thereof

The present invention relates to a method of preparing a vinyl chloride polymer having good thermal stability due to the restraint of dehydrochlorination by heat or ultraviolet rays, and a vinyl chloride polymer prepared thereby. In the preparation method through bulk polymerization, a modifier is introduced to a polymerization process to impart the vinyl chloride polymer with high thermal stability without inducing modification. Therefore, the preparation method via the bulk polymerization of the vinyl chloride polymer and the vinyl chloride polymer prepared thereby according to the present invention may be readily applied to industries requiring thereof such as industries concerning a vinyl chloride resin and the molded article thereof.

Owner:LG CHEM LTD

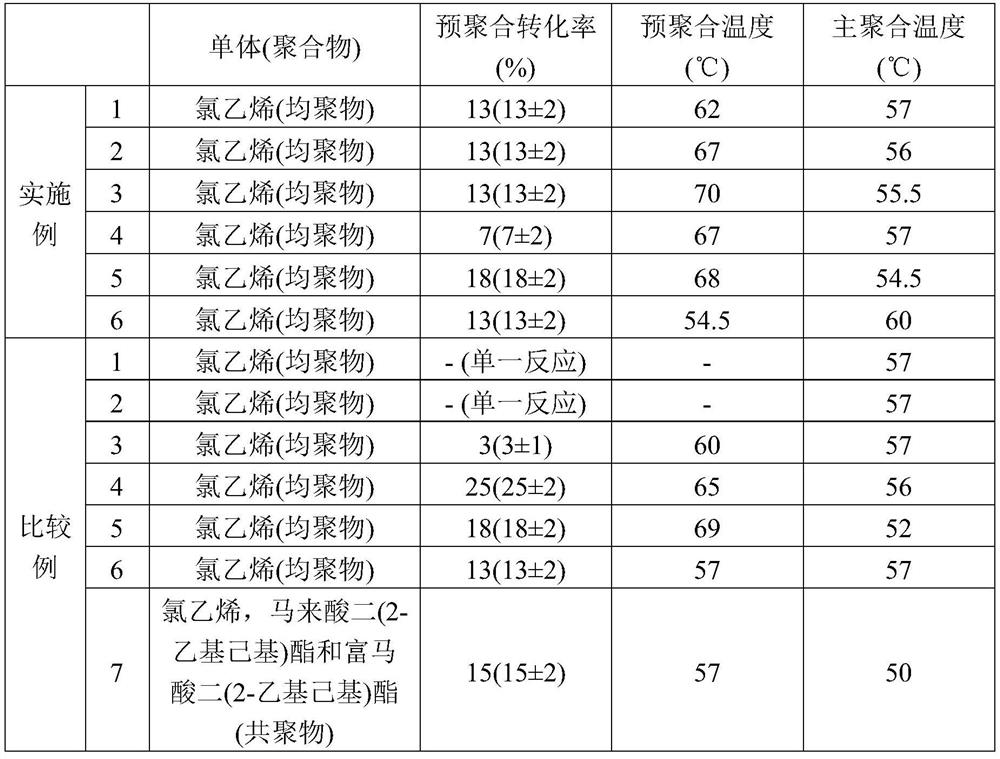

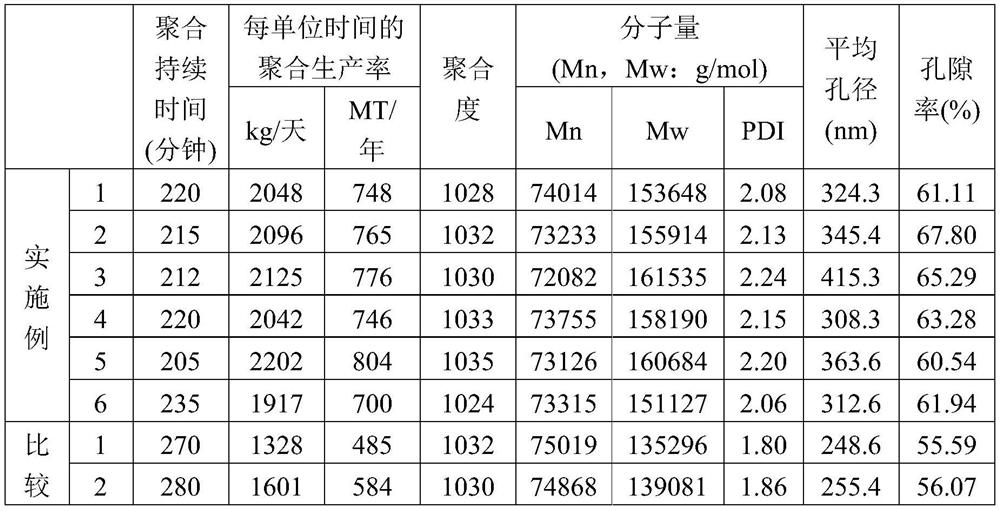

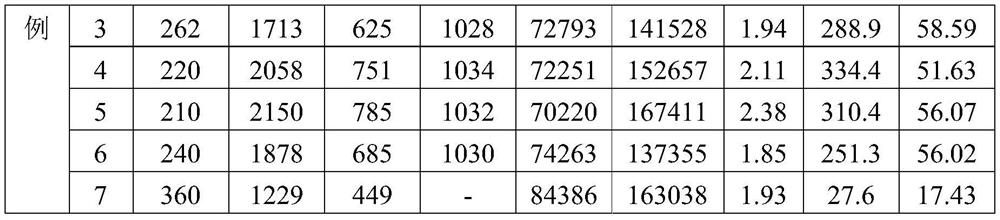

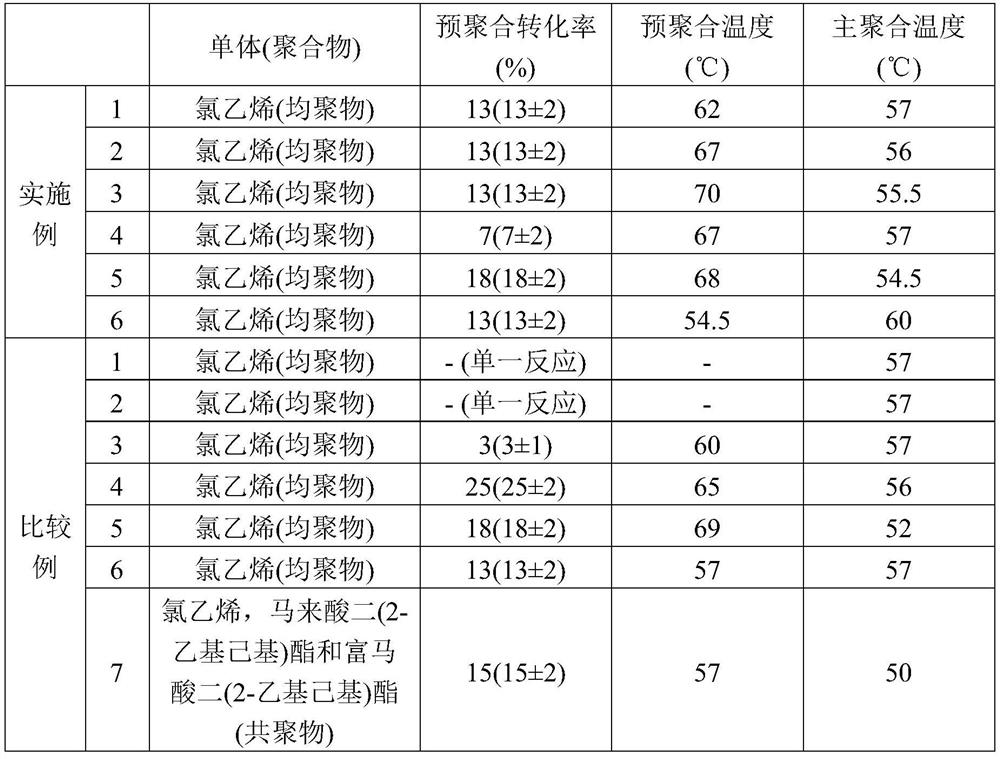

Vinyl chloride polymer and method for preparing same

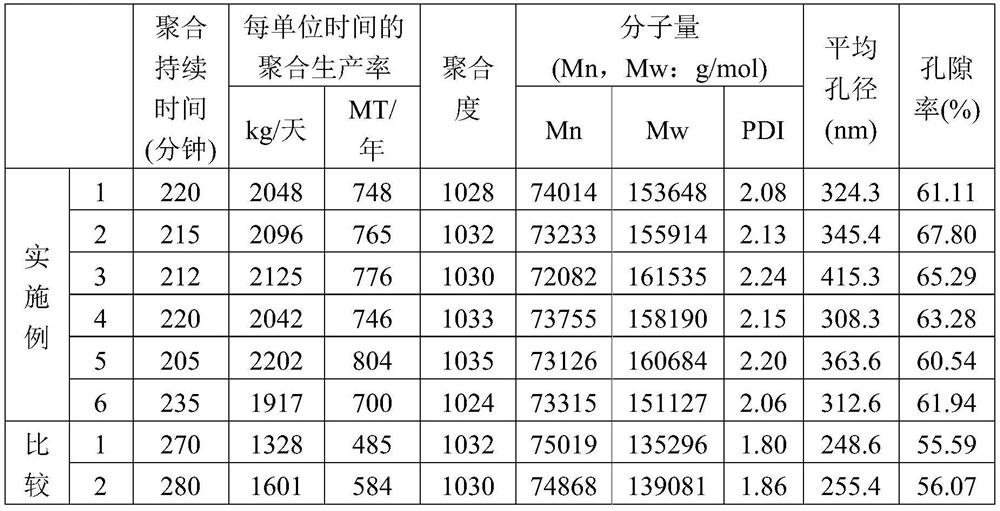

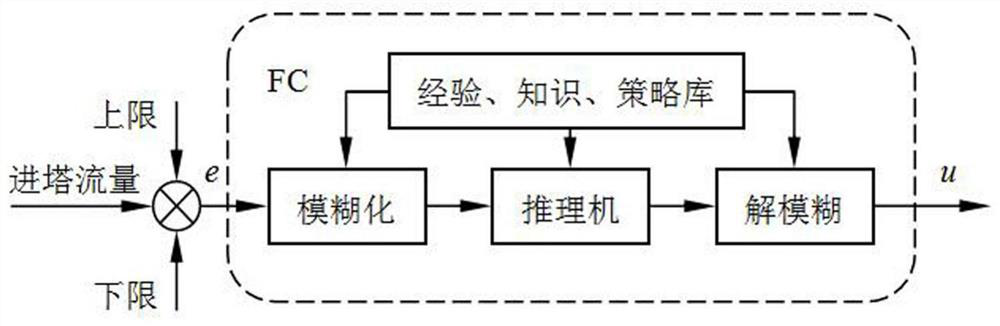

The present invention relates to a vinyl chloride polymer and a method for preparing same and, more specifically, to a vinyl chloride polymer of which the polydispersity index is 2.0 to 2.3 and the porosity is 60% or higher, and a method for preparing the vinyl chloride polymer. More particularly, in the method for preparing the vinyl chloride polymer, a vinyl chloride polymerization seed having aconversion rate of 5 to 20% is first prepared by means of prepolymerization, and then a vinyl chloride monomer is input to the vinyl chloride polymerization seed and a vinyl chloride polymer is polymerized (main polymerization), wherein the temperature differential between the prepolymerization and the main polymerization is adjusted to 5 to 15 DEG C. The preparation method has the advantage of increasing polymerization productivity. The vinyl chloride polymer polymerized by means of the preparation method shows said physical properties and thus has the advantages of enhancing the fish eye quality and initial coloration as well as enabling excellent processability.

Owner:LG CHEM LTD

Vinyl chloride polymer and its preparation method

Owner:LG CHEM LTD

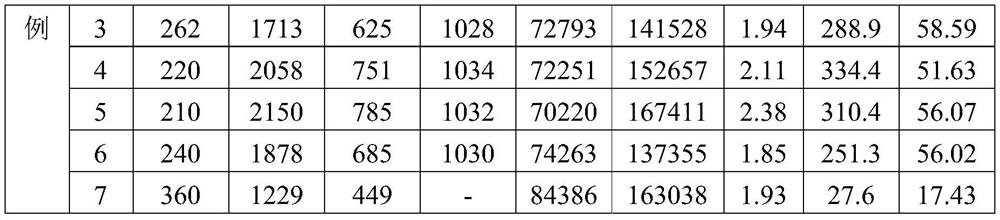

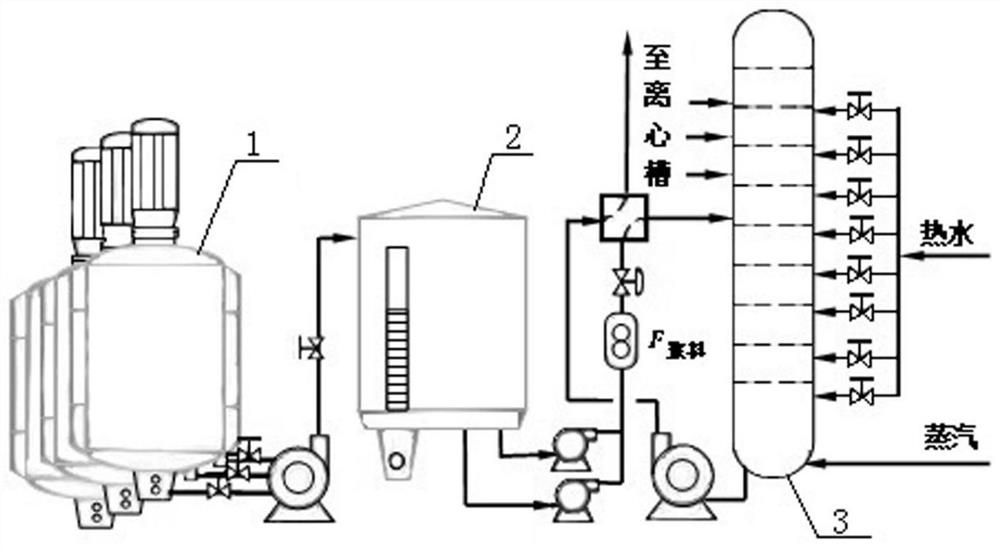

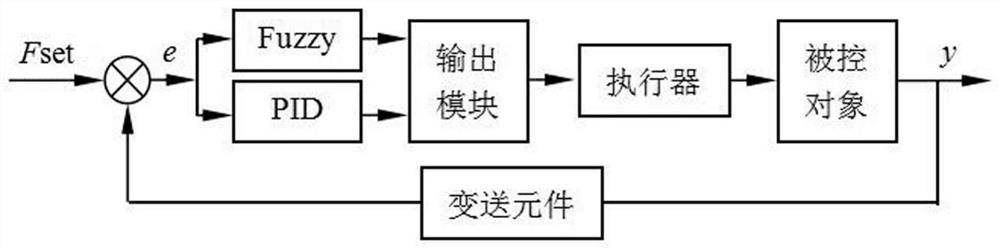

Material balance intelligent control method for post-treatment of polyvinyl chloride polymer

ActiveCN113589774AGuarantee the efficacy of removing residual vinyl chlorideAvoid material breakTotal factory controlProgramme total factory controlMaterial balancePolyvinyl chloride

The invention discloses a material balance intelligent control method for post-treatment of polyvinyl chloride polymer. The material balance intelligent control method comprises the following steps: S1, calculating the feeding amount of a stripping tower on line; s2, adjusting and balancing the feeding amount of the stripping tower while the step S1 is carried out; and gradually iteratively adjusting the temperature and the feeding flow in the stripping tower according to a set flow adjustment target value by adopting a hill climbing algorithm. The online calculation of the feeding amount of the stripping tower is a fundamental way for solving automatic balance; meanwhile, in the flow adjusting process, the temperature and the feeding flow in the tower are gradually and iteratively adjusted according to a set flow adjusting target value by adopting a hill climbing algorithm similar to the nature, so that the effect of removing the residual vinyl chloride is ensured, and the material balance of polymerization kettle-polymer post-treatment in polyvinyl chloride resin production and the automatic control of the operation of the stripping tower are realized; the working condition is stable, collision-free switching is achieved, operation is safe, and material balance and process indexes are ensured.

Owner:辛集市智胜中小企业技术服务有限公司

Vinyl chloride polymer and preparation method thereof

The present invention relates to a method of preparing a vinyl chloride polymer having good thermal stability due to the restraint of dehydrochlorination by heat or ultraviolet rays, and a vinyl chloride polymer prepared thereby. In the preparation method, a modifier is introduced at the end of a polymerization process to impart the vinyl chloride polymer with high thermal stability without inducing modification. Therefore, the generation of dehydrochlorination due to heat or ultraviolet rays may be markedly restrained, thermal stability may be improved, and discoloration or the modification of physical properties may be prevented in the vinyl chloride polymer thus prepared.

Owner:LG CHEM LTD

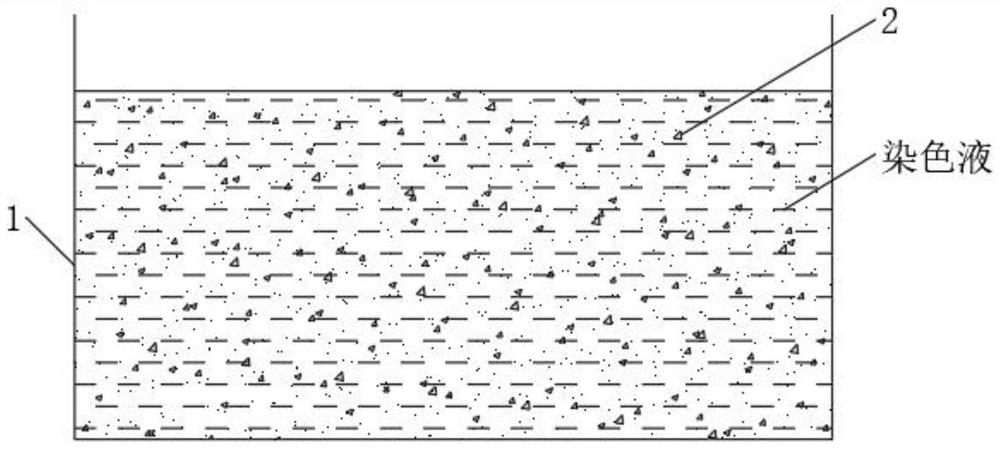

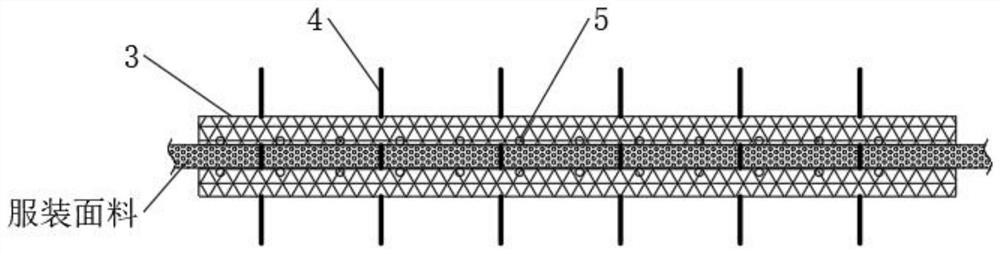

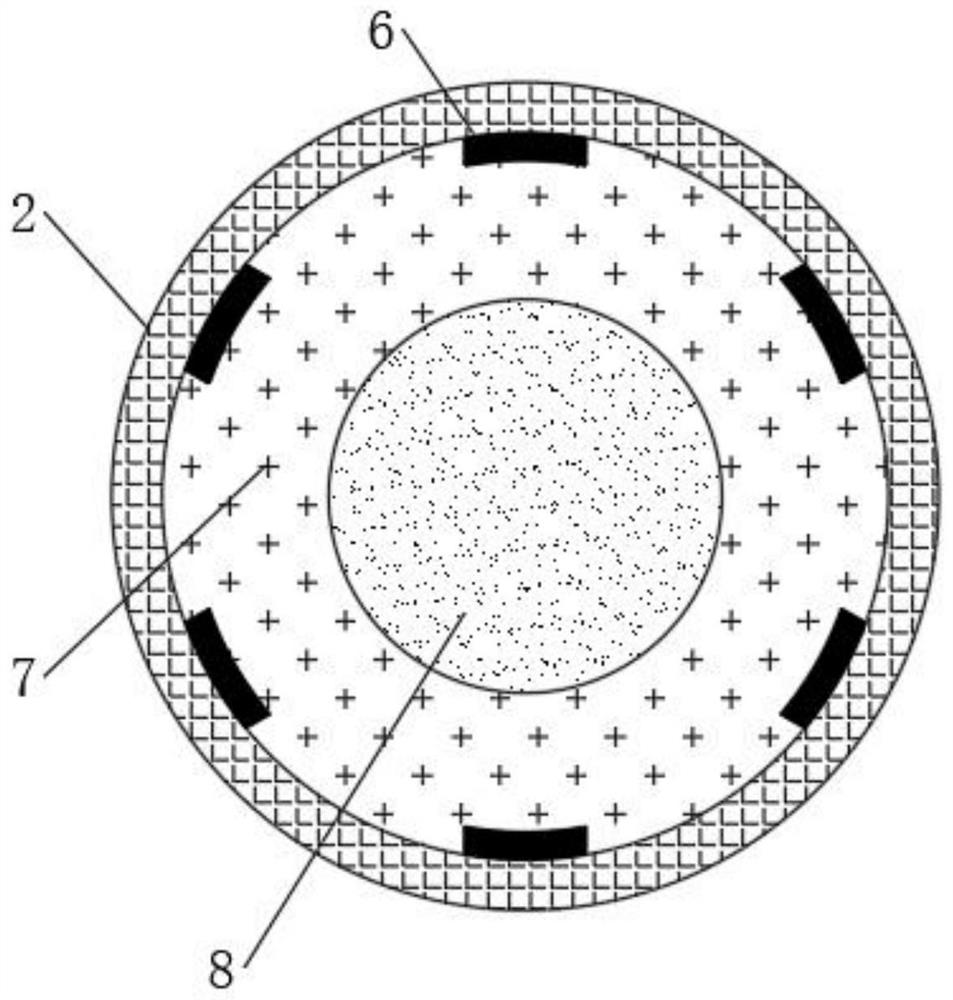

Temperature-sensing garment printing and dyeing process

InactiveCN112761003AEvenly distributedReversible thermochromic effectDyeing processFiberProcess engineering

The invention discloses a temperature-sensing garment printing and dyeing process, and belongs to the field of garment printing and dyeing. The temperature-sensing garment printing and dyeing process comprises the steps that storage balls are put into dyeing liquid to be evenly distributed in a dyeing pool, a net-shaped limiting plate clamps the outer side of a garment fabric, ejector pins are inserted into the outer side of the net-shaped limiting plate and penetrate through the garment fabric, one ends of the ejector pins are inserted into the storage balls through adsorption between magnetic adsorption blocks on the inner walls of the storage balls and magnetic fiber, so that a dissolving solution and thermochromic powder are mixed and then enter the garment fabric along the ejector pins, and a mixed solution of the dissolving solution and the thermochromic powder is uniformly dispersed in the garment fabric through the magnetic fiber; and the dyeing liquid is heated, the hot-melting fusion balls are melted through high temperature, so that thermosensitive color-changing microcapsules enter fibers of the garment fabric, the vinyl chloride polymer solution adheres to the outer side of the garment fabric, and the solution becomes gel through heat treatment, so that the reversible thermosensitive color-changing effect is achieved.

Owner:许爱萍

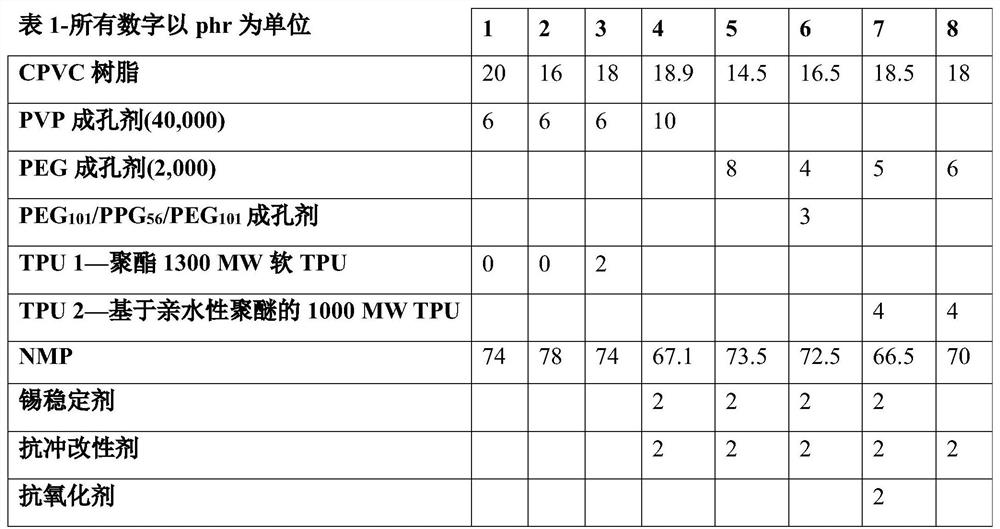

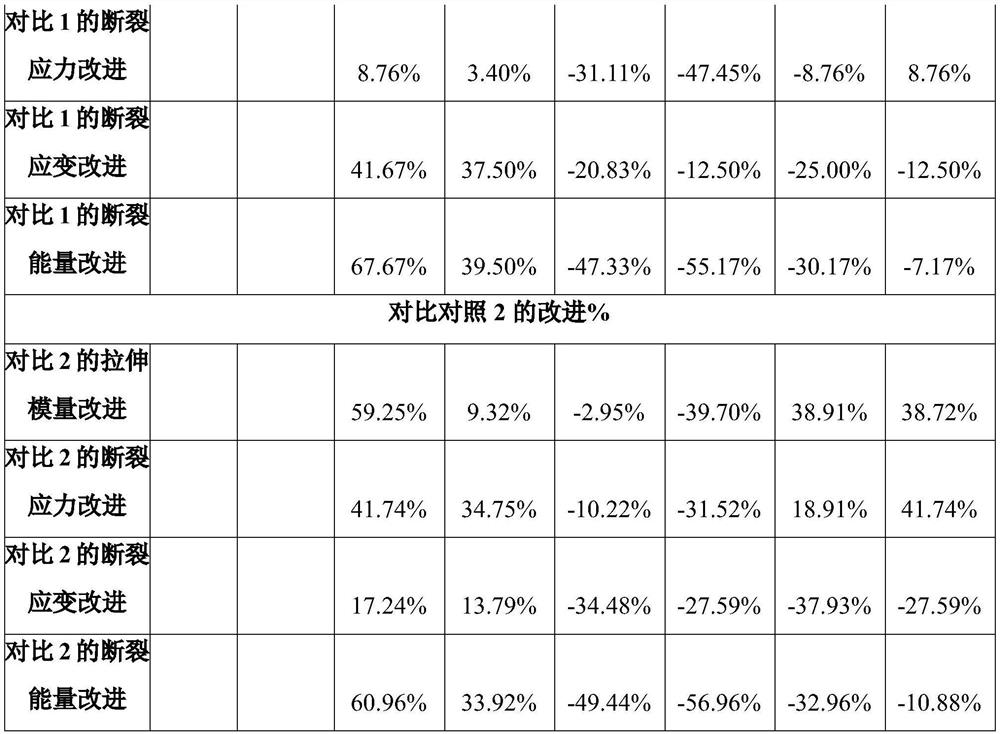

Hollow fiber membrane

PendingCN114206483ASolve chemical degradation problemsAvoid breakingMembranesSemi-permeable membranesPolymer scienceChlorinated polyvinyl chloride

The disclosed technology relates to hollow fiber membranes prepared from a coating solution comprising a vinyl chloride polymer (e.g., chlorinated polyvinyl chloride) and a thermoplastic polyurethane.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Preparation method and application of vinyl chloride polymer

The invention discloses a preparation method and application of a vinyl chloride polymer, and relates to the technical field of vinyl chloride; the method comprises the following steps: putting vinylchloride and an anti-bonding agent into a reactor; vacuumizing the reactor until the pressure is -0.1 MPa to -0.05 MPa, then introducing chlorine until the pressure in the reactor is 0.2 MPa to 0.6 MPa, carrying out chlorination reaction, discharging reaction waste gas after the reaction is finished, and repeating the operations of vacuumizing, introducing the chlorine for chlorination reaction and discharging the waste gas, so as to obtain chlorinated polyvinyl chloride. According to the preparation method of the vinyl chloride polymer according to the invention, the preparation method for the vinyl chloride polymer by bulk polymerization and the vinyl chloride polymer produced thereby can be easily applied to industries requiring vinyl chloride polymers, such as industries involving vinyl chloride resins and molded articles thereof.

Owner:HWASU

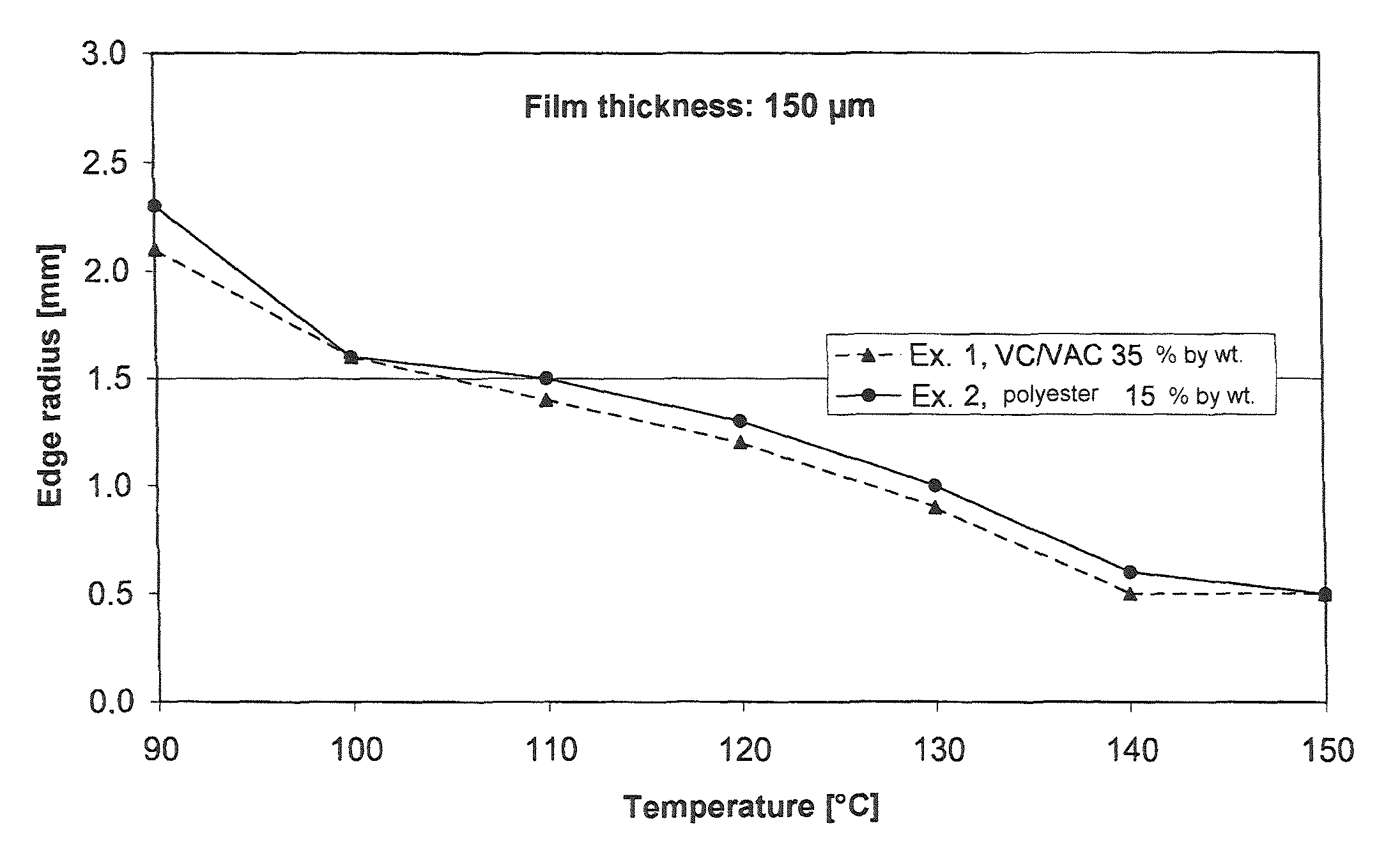

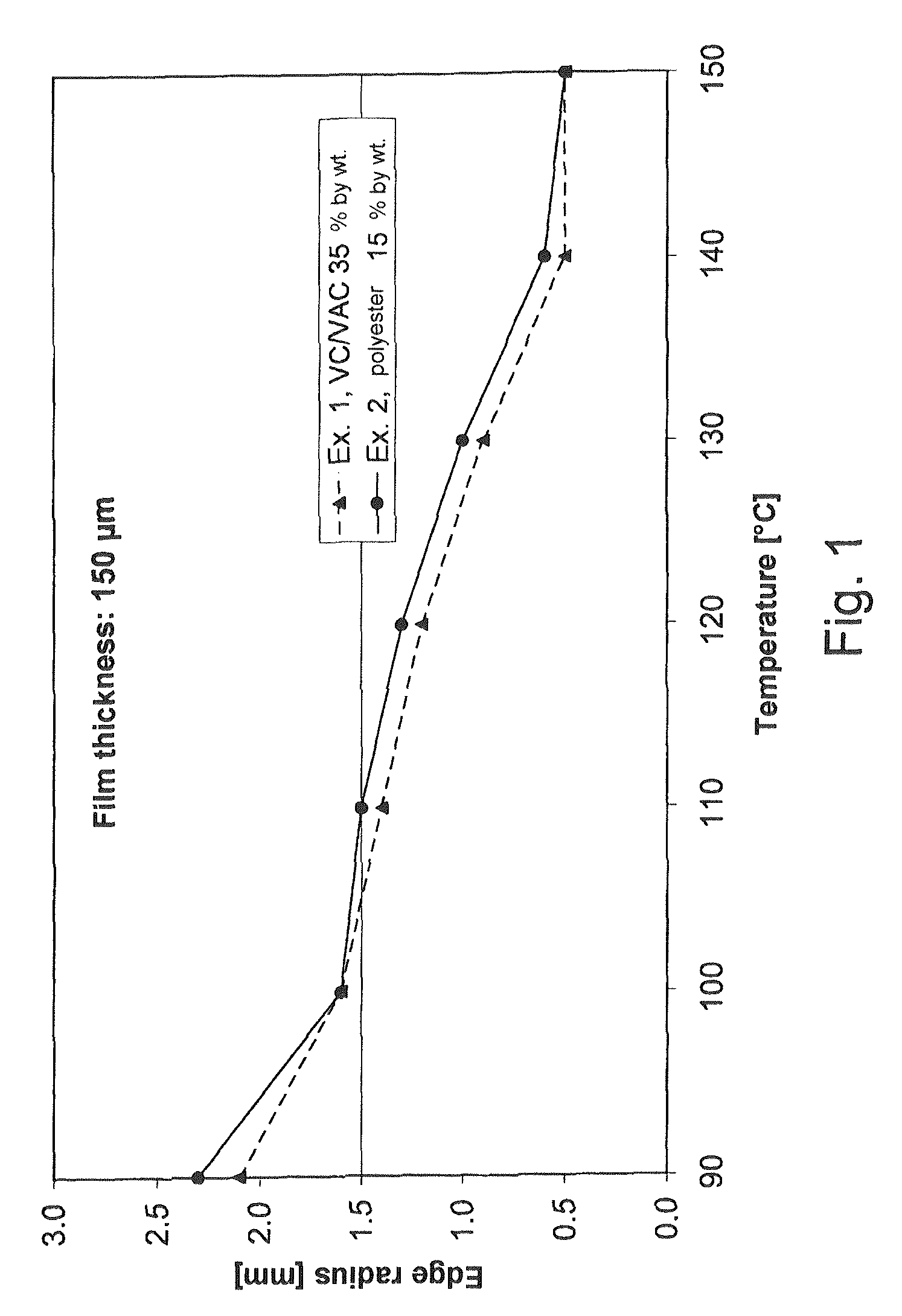

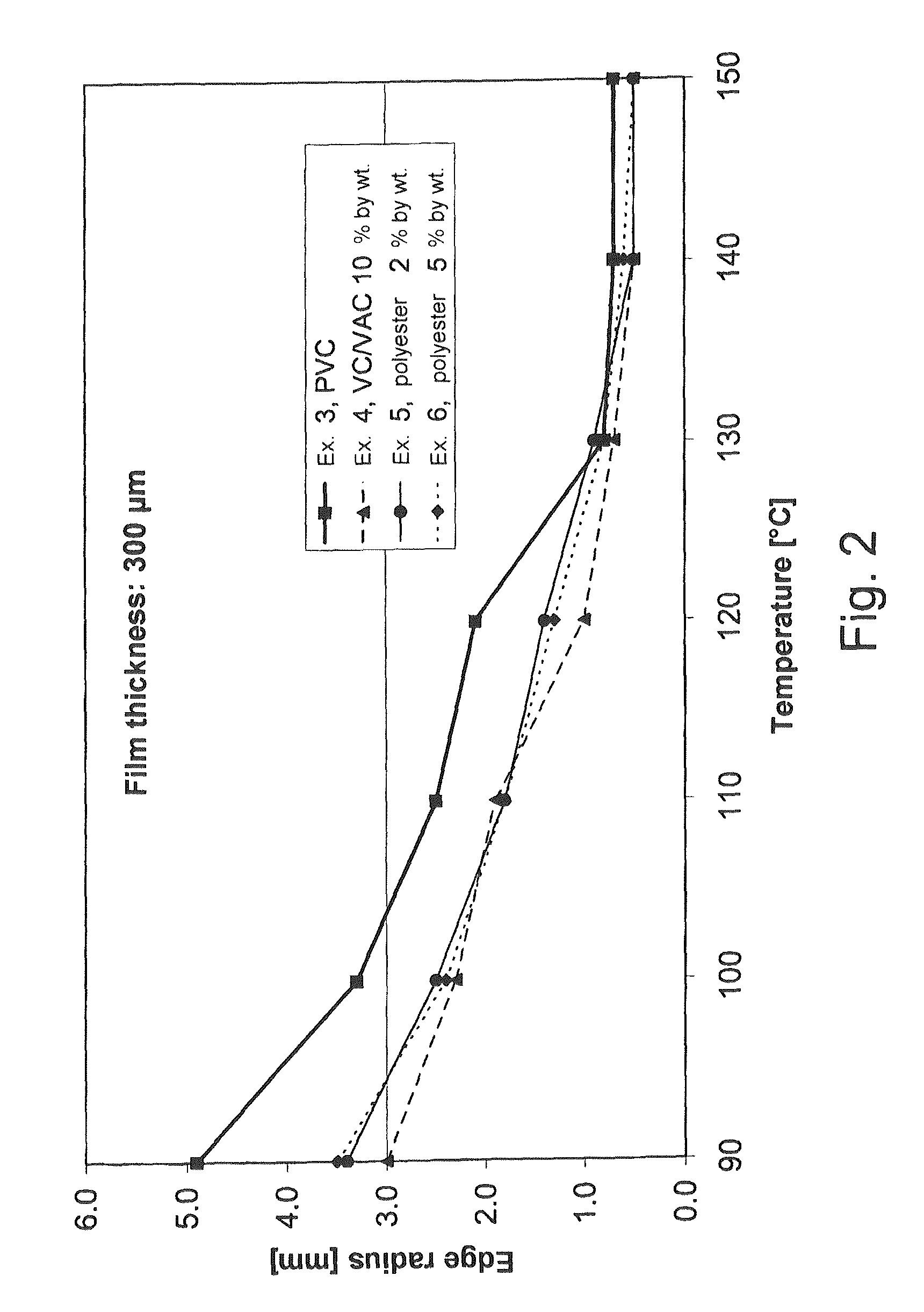

Vinyl chloride polymer film and method for producing same

ActiveUS8808846B2Excellent thermoformabilitySimple additive formulationSynthetic resin layered productsPolyesterVinylchloride polymer

The invention relates to a film made of a vinyl chloride polymer mixture that, in addition to the conventional additives, contains 0.1 to less than 5 wt % of a semicrystalline or amorphous polyester, has a good thermal formability, and is suitable for the packaging of bulk goods. The film is produced by extruding or by calendering the plastified vinyl chloride polymer mixture, optionally followed by inline / offline stretching and, optionally, thermally formed immediately thereafter.

Owner:KLOECKNER PENTAPLAST

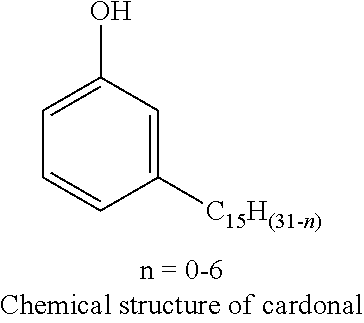

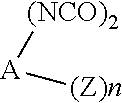

Cardanol blocked isocyanate adhesion promotor for PVC plastisol

The present invention relates to a PVC plastisol composition comprising at least one vinyl chloride polymer selected from polyvinylchlorides and copolymers of vinyl chloride with one or more monomers; at least one plasticizer; at least one epoxy resin; and at least one isocyanate resin blocked with cardanol. The PVC plastisol composition of this invention provides strong adhesion to the surface of various metals or various undercoats of metals by thermal treatment for a short time at 100° C.-200° C. and is excellent in storage stability. In addition, it offers good rheological properties with improved yield value dosing and viscosity stability during applications compared to the nonylphenol blocked isocyanate PVC adhesion promotor.

Owner:EVONIK OPERATIONS GMBH

Transparent chlorinated polyethylene thermoplastic material

The invention relates to the technical field of plastic products, in particular to a transparent chlorinated polyethylene thermoplastic material. The technical scheme is that: the transparent chlorinated polyethylene thermoplastic material consists of 80 to 95 mass percent of chloroethylene polymer and 5 to 20 mass percent of chlorinated polyethylene, wherein the chlorinated polyethylene consistsof two kinds of high density chlorinated polyethylene B1 and B2 with different parameters; the high density chlorinated polyethylene B1 accounts for 2.5 to 10 percent of the total mass of the material, and has the chlorine content of 37-42 percent, the residual value of 0-30 percent and the swell value of 10-70 percent; and the high density chlorinated polyethylene B2 accounts for 2.5 to 10 percent of the total mass of the material, and has the chlorine content of 37-42 percent, the residual value of 50-70 percent and the swell value of 1-2 percent. The chlorinated polyethylene has simple components; the preparation method is simple, convenient and low in cost; and the thermoplastic material prepared from the chlorinated polyethylene has good toughness and transparency and good light fastness and weather change resistance.

Owner:山东旭业新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com