Method for preparing mesopore-micropore composite porous carbon on basis of vinylidene chloride polymers

A technology of vinylidene chloride and partial vinylidene chloride, which is applied in the field of preparation of porous carbon materials to achieve the effects of narrow pore size distribution, good application prospects and good correspondence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

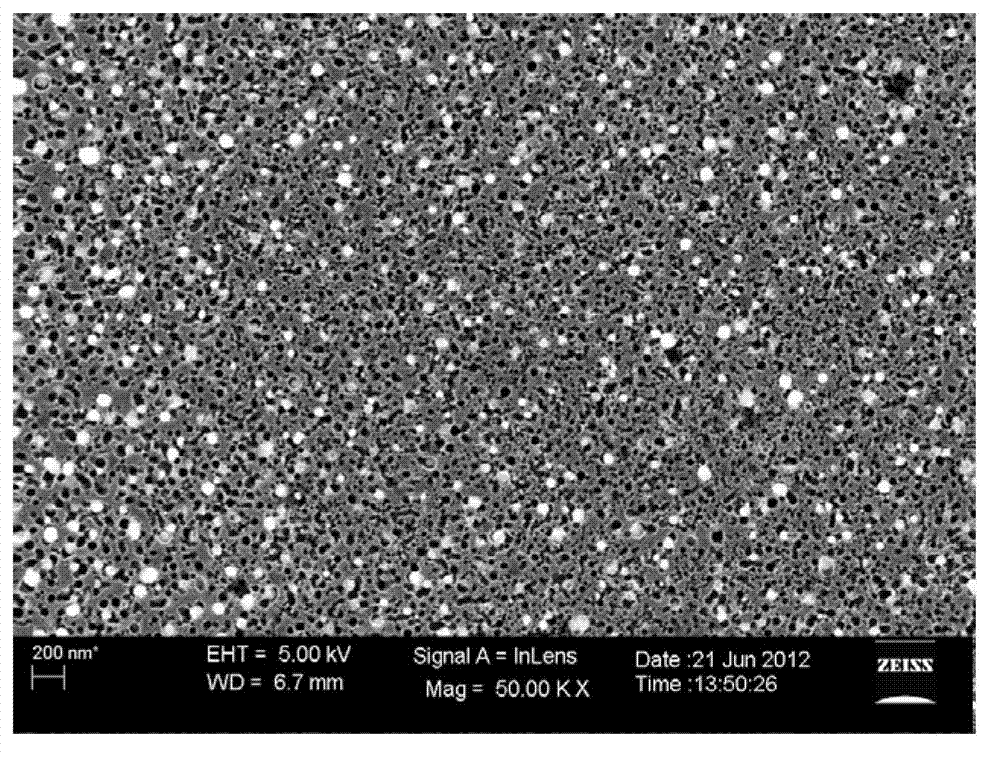

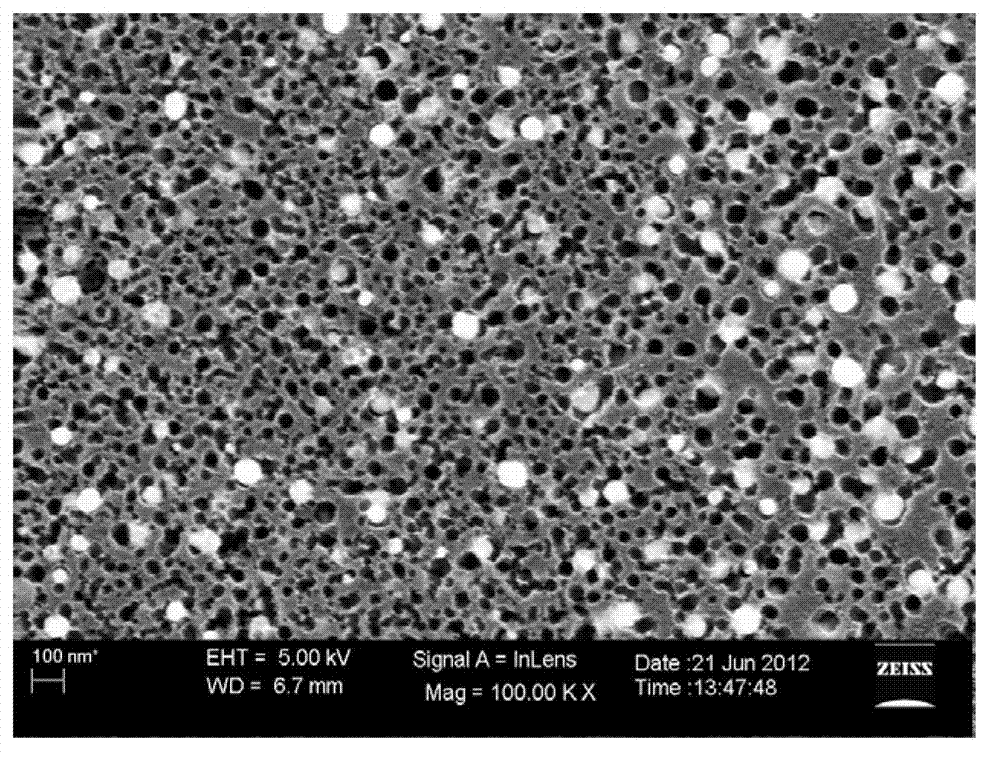

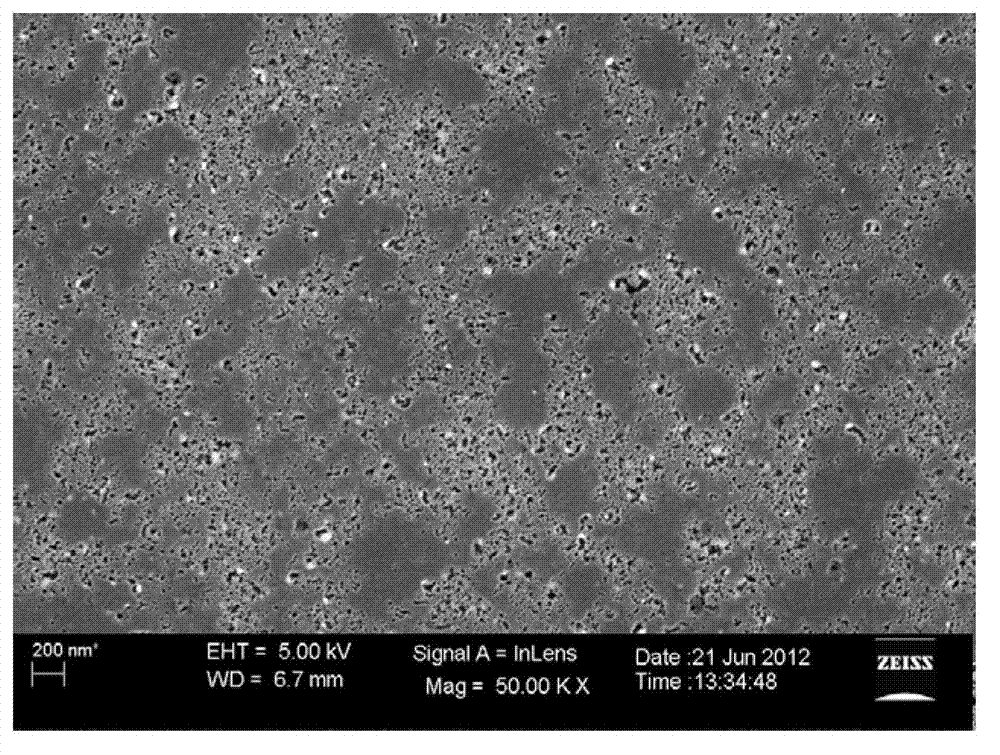

Image

Examples

preparation example Construction

[0024] The steps of a preparation method of a vinylidene chloride polymer-based mesopore-microporous composite porous carbon are as follows:

[0025]1) Add 50-100 parts by mass of 1,4-dioxane, 5-20 parts by mass of vinylidene chloride, 2-7 parts by mass of polyethylene glycol-based macromolecular RAFT reagent, 0.016-0.16 parts by mass Azobisisobutyronitrile, stir at room temperature for 10-30 minutes to dissolve and mix the reactants, pass nitrogen to remove oxygen, heat to 60-70°C, and polymerize for 18-24 hours; add a precipitant to the reaction solution, precipitate, separate, and dry Obtain a block copolymer composed of vinylidene chloride (co)polymer and polyethylene glycol;

[0026] 2) Put the prepared block copolymer of vinylidene chloride (co)polymer and polyethylene glycol into a crucible, put it into a high-temperature furnace, and first pass a protective inert gas into the high-temperature furnace for 30-60 minutes, and take 2 ℃ / min~10℃ / min to raise the temperature...

Embodiment 1

[0032] Add 0.007mol of polyethylene glycol with a molecular weight of 2000 and 0.0156mol of S-1-dodecyl-S'-(α,α'-dimethyl-α''-acetic acid) trithiocarbonate Reactor, use 1.1mol of dichloromethane as solvent, stir and disperse, then add 0.003mol of catalyst 4-dimethylaminopyridine, continue to stir and disperse evenly, then add 0.0155mol of water remover dicyclohexylcarbodiimide, 25℃ Stirring and reacting for 24 hours, the product was precipitated and filtered, and the precipitated solid was dissolved with dichloromethane and precipitated with petroleum ether. This operation was repeated three times, and finally the product was dried to obtain a macromolecular RAFT chain transfer agent.

[0033] 2 grams of modified polyethylene glycol 2000 macromolecule RAFT chain transfer agent, 0.015 grams of azobisisobutyronitrile, 10.8 grams of vinylidene chloride and 1.2 grams of methyl acrylate were added to a 200 milliliter reactor, and then Add 100 ml of reaction solvent 1,4-dioxane, sti...

Embodiment 2

[0036] Add 0.007mol of polyethylene glycol with a molecular weight of 6000 and 0.0156mol of S-1-dodecyl-S'-(α,α'-dimethyl-α''-acetic acid) trithiocarbonate Reactor, use 0.91mol of dichloromethane as solvent, stir and disperse, then add 0.003mol of catalyst 4-dimethylaminopyridine, continue to stir and disperse evenly, add 0.0155mol of water remover dicyclohexylcarbodiimide, 25℃ Stirring and reacting for 48 hours, the product was precipitated and filtered, and the precipitated solid was dissolved with dichloromethane and precipitated with petroleum ether. This operation was repeated three times, and finally the product was dried to obtain a macromolecular RAFT chain transfer agent.

[0037] 6.4 gram of modified polyethylene glycol 6000 macromolecule RAFT chain transfer agent, 0.015 gram of azobisisobutyronitrile, 10.8 gram of vinylidene chloride and 1.2 gram of methyl acrylate are added to 200 milliliters of autoclave, and then Add 100 ml of reaction solvent 1,4-dioxane, stir a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com