Hollow fiber membrane

A fiber membrane, hollow technology, applied in the direction of fiber treatment, fiber chemical characteristics, membrane, etc., can solve the problem of efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

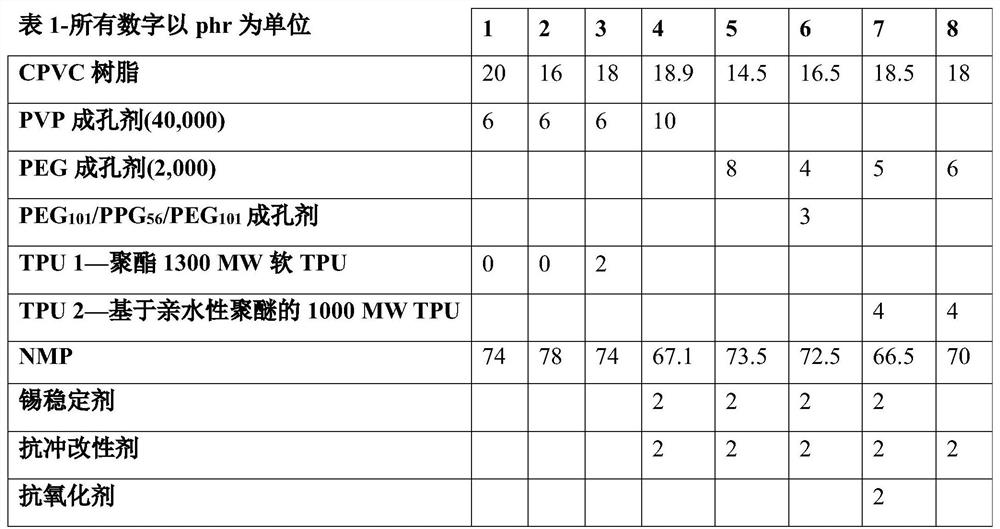

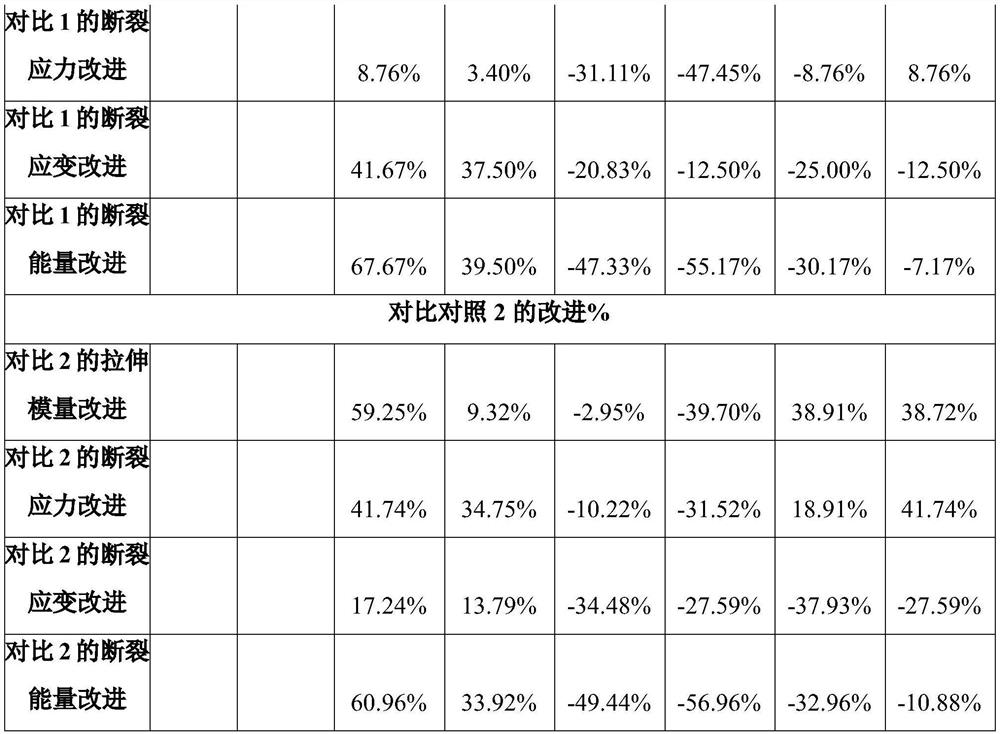

[0095] Hollow fiber membranes were prepared from the coating solutions shown in Table 1 below.

[0096]

[0097] A coating solution was prepared by dissolving chlorinated polyvinyl chloride (CPVC) in N-methyl-2-pyrrolidone (NMP). The CPVC was weighed and added to the NMP at 55°C for 16 hours with continuous stirring. After dissolving the CPVC using this method, additional formulation additives were added at 60° C. for 4 hours using the same continuous stirring conditions.

[0098] In order to manufacture hollow fiber membranes from the above coating solution, typical hollow manufacturing equipment is used for the manufacturing process. The equipment consists of two reservoirs, a spinneret, a water bath and a winding unit. Fully formulated coating solution and drilling fluid are placed in separate reservoirs. The two fluids are pumped through a spinneret die that has channels cut into it for the flow of the coating fluid and the drilling fluid. This spinneret can create ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com