Temperature-sensing garment printing and dyeing process

A printing and dyeing process, clothing technology, applied in the field of clothing printing and dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

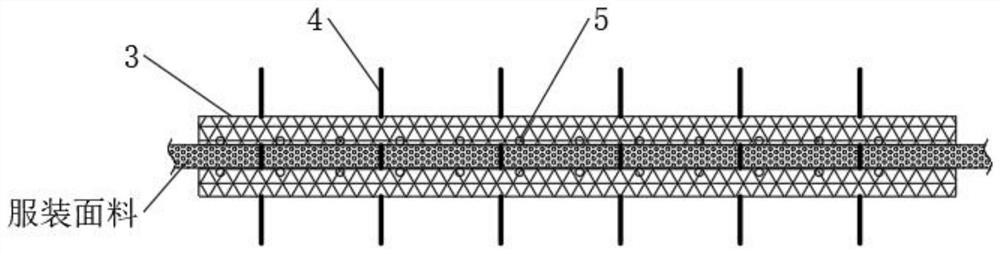

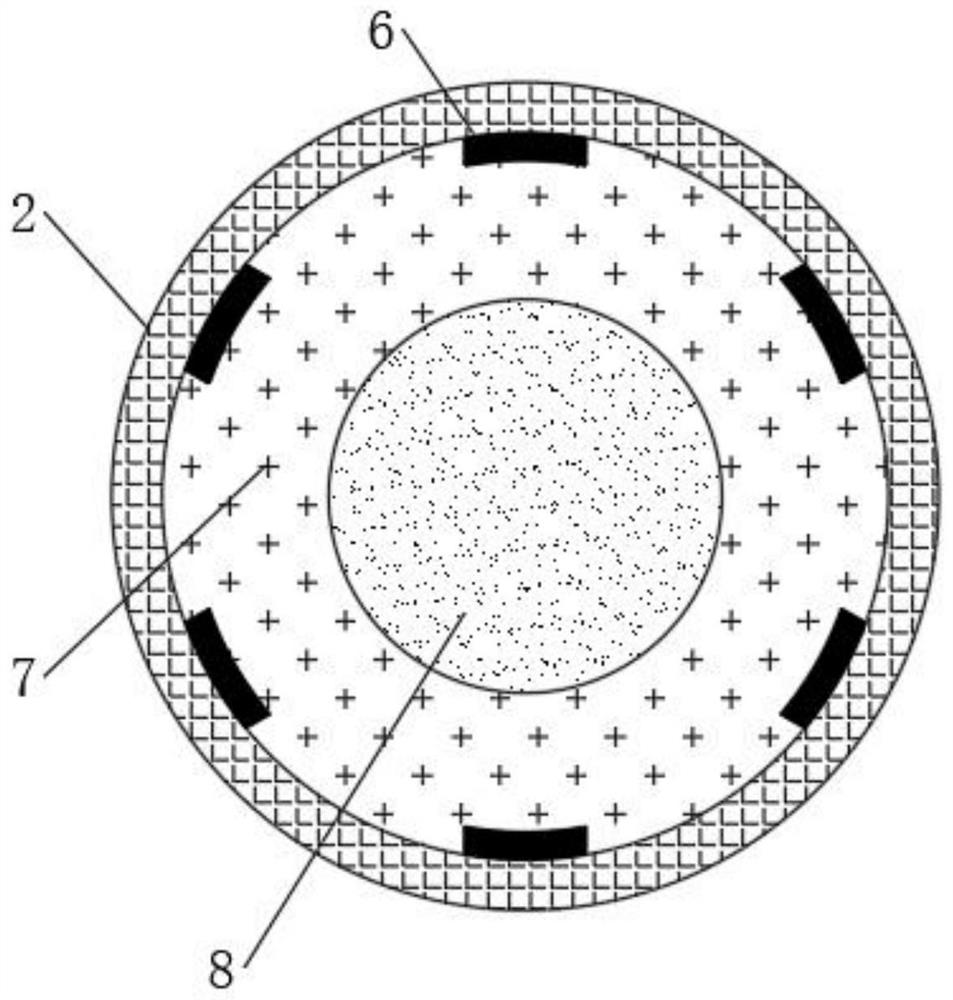

[0043] see Figure 1-5 , a temperature-sensing garment printing and dyeing process, comprising the following steps:

[0044] S1. In the pretreatment stage, the clothing is immersed in 2.5g / L of detergent for 10 minutes, washed, and dried;

[0045] S2, mixing 9 parts of comonomers with 120 parts of water to obtain a modified liquid; wherein, the comonomers include 2-acrylamide-2-methylpropanesulfonic acid and acrylonitrile;

[0046] S3, immerse the garment processed in step S1 in the modification liquid, after ultrasonic vibration for 25min, add an initiator whose weight is 6% of the weight of the comonomer to the modification liquid, and microwave polymerization under microwave conditions;

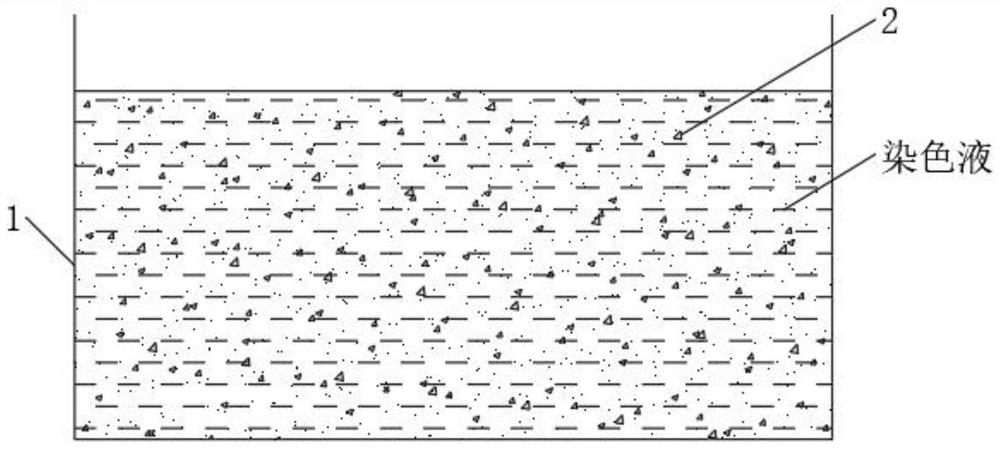

[0047] S4, disperse the cationic reactive dyes in water to form a mixed solution with a concentration of 1.7 g / L, add a printing and dyeing auxiliaries to the mixed solution to obtain a dyeing solution and pour it into the dyeing tank 1, wherein the printing and dyeing auxiliaries and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com