Preparation method of vinyl chloride polymer ionic liquid porous membrane

A vinyl chloride polymer and ionic liquid technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of ionic liquid recovery that has not been solved, and achieve good self-cleaning and anti-pollution performance, Good mechanical properties, easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

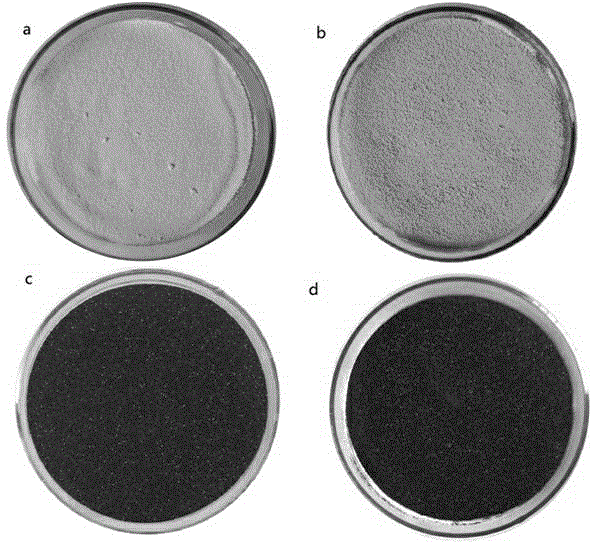

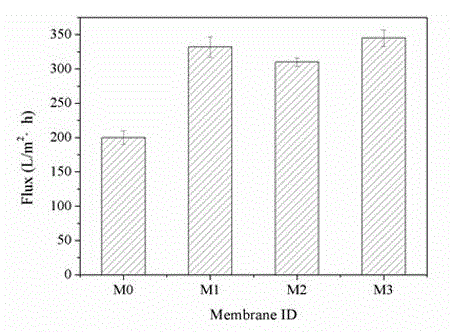

[0024] Preparation process of polyvinyl chloride polymer ionic liquid porous membrane:

[0025] (1) Preparation of vinyl chloride polymer ionic liquid: Disperse polyvinyl chloride powder in a mixed solvent of ethanol and water, the volume ratio of ethanol and water is 5:1, then add N-methylimidazole, polyvinyl chloride powder The mass ratio to N-methylimidazole is 1:4, under argon protection, then add NaOH equivalent to N-methylimidazole, react at 70°C for 24h, cool the solution, centrifuge, and wash repeatedly with ethanol and deionized water, Dry in a vacuum oven at 25°C to prepare vinyl chloride polymer ionic liquid (PVC-mimOH);

[0026] (2) Preparation of vinyl chloride polymer ionic liquid porous membrane: Dissolving vinyl chloride polymer ionic liquid powder (PVC-mimOH) and polyvinylpyrrolidone in dimethyl sulfoxide to prepare vinyl chloride polymer ionic liquid (PVC-mimOH) -mimOH) with a proportion of 15wt% of the casting film solution, stirred at 70°C until uniform; t...

Embodiment 2

[0029] Preparation process of polyvinyl chloride polymer ionic liquid porous membrane:

[0030] (1) Preparation of vinyl chloride polymer ionic liquid: Disperse polyvinyl chloride powder in a mixed solvent of ethanol and water, the volume ratio of ethanol and water is 3:1, then add N-methylimidazole, polyvinyl chloride powder The mass ratio to N-methylimidazole is 1:4, under argon protection, then add NaOH equivalent to N-methylimidazole, react at 70°C for 24h, cool the solution, centrifuge, and wash repeatedly with ethanol and deionized water, Dry in a vacuum oven at 25°C to prepare vinyl chloride polymer ionic liquid (PVC-mimOH);

[0031] (2) Preparation of vinyl chloride polymer ionic liquid porous membrane: Dissolving vinyl chloride polymer ionic liquid powder (PVC-mimOH) and polyvinylpyrrolidone in dimethyl sulfoxide to prepare vinyl chloride polymer ionic liquid (PVC-mimOH) -mimOH) with a proportion of 15wt% of the casting film solution, stirred at 70°C until uniform; t...

Embodiment 3

[0034] Preparation process of polyvinyl chloride polymer ionic liquid porous membrane:

[0035] (1) Preparation of vinyl chloride polymer ionic liquid: Disperse polyvinyl chloride powder in a mixed solvent of ethanol and water, the volume ratio of ethanol and water is 1:1, then add N-methylimidazole, polyvinyl chloride powder The mass ratio to N-methylimidazole is 1:4, under argon protection, then add NaOH equivalent to N-methylimidazole, react at 70°C for 24h, cool the solution, centrifuge, and wash repeatedly with ethanol and deionized water, Dry in a vacuum oven at 25°C to prepare vinyl chloride polymer ionic liquid (PVC-mimOH);

[0036] (2) Preparation of vinyl chloride polymer ionic liquid porous membrane: Dissolving vinyl chloride polymer ionic liquid powder (PVC-mimOH) and polyvinylpyrrolidone in dimethyl sulfoxide to prepare vinyl chloride polymer ionic liquid (PVC-mimOH) -mimOH) with a proportion of 15wt% of the casting film solution, stirred at 70°C until uniform; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water flux | aaaaa | aaaaa |

| Water flux | aaaaa | aaaaa |

| Water flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com