Vinyl chloride polymers and compositions for additive manufacturing

A technology for additive manufacturing, composition, in the field of chlorinated thermoplastic polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

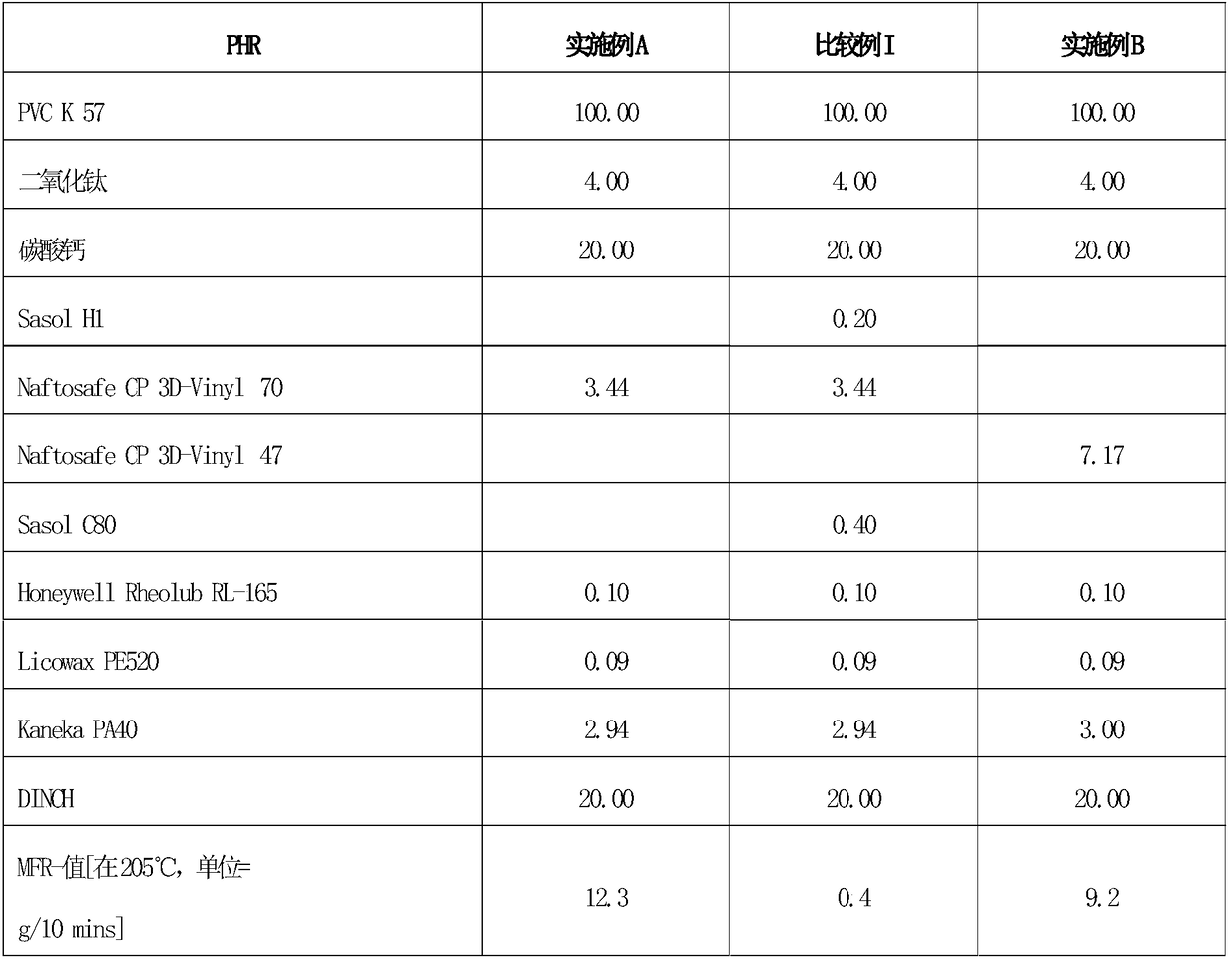

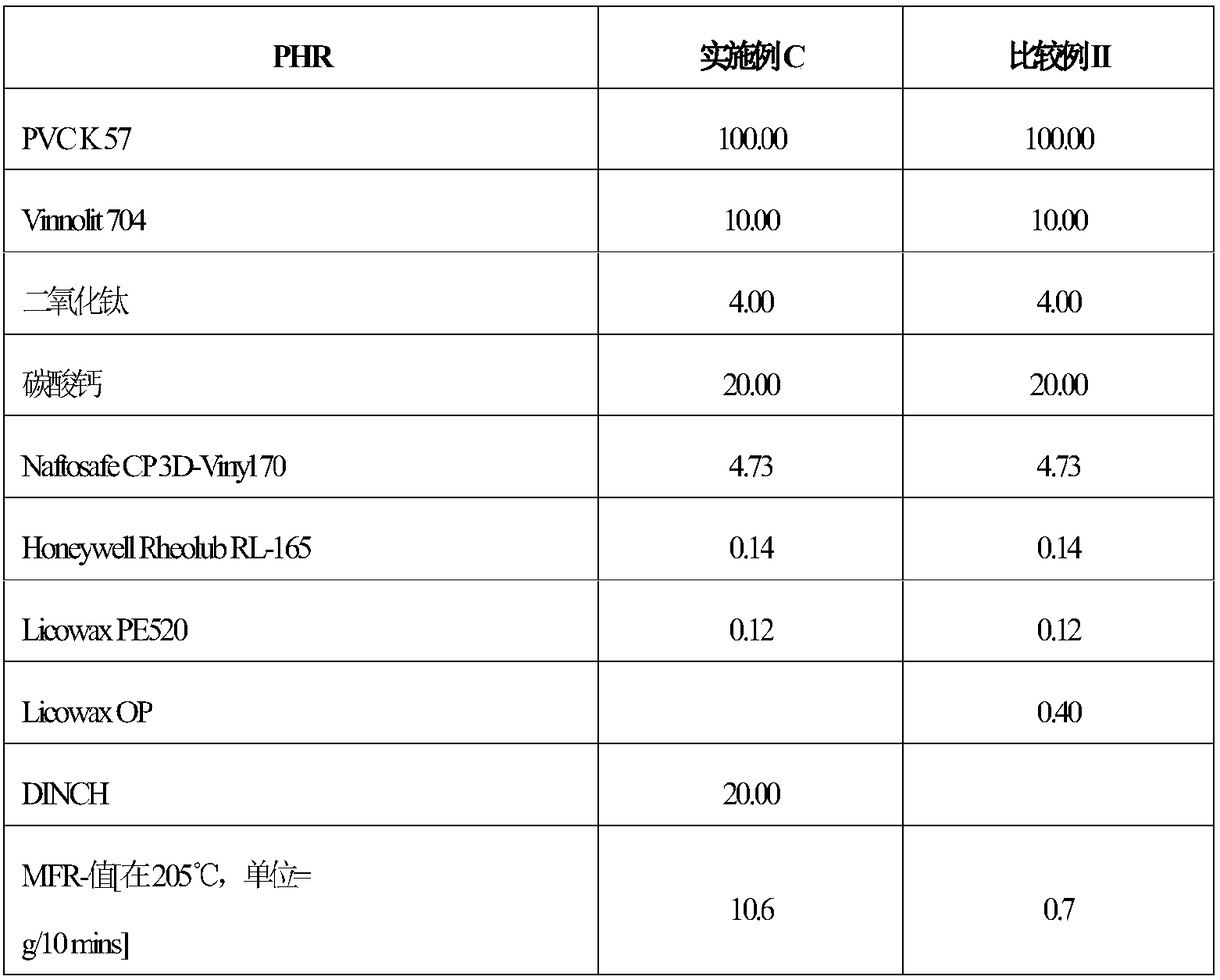

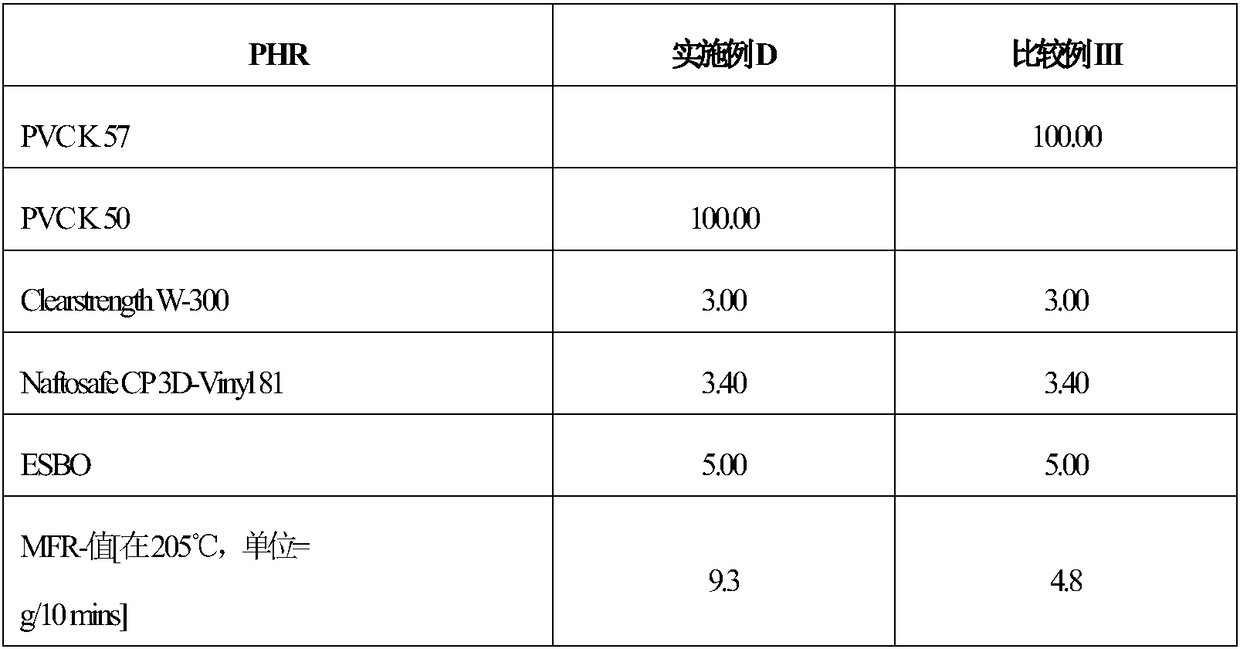

[0128] The following PVC rigid compositions are made into dry mixes, usually mixed to 120°C; for compositions containing plasticizers, the plasticizer is added at 60°C and the dry mix is mixed to 110°C, such as PVC Standard procedure for processing. The dry blend was then extruded into 1.75 mm diameter strands with a Polylab laboratory twin-screw extruder under standard extrusion conditions.

[0129] The obtained wires were 3D printed on a Reprap-type "Makergear M Series" 3D printer to become 3D printed test pieces for evaluating 3D printing performance (http: / / www.thingiverse.com / thing:704409t). The 3D printing parameters are adjusted to the following conditions: the printing speed is 50mm / s; the printing temperature that starts printing immediately when PVC enters the "hot end" can be manually set to 190 to 290°C on the main program; once PVC enters the "hot end" The bed temperature that starts printing immediately at "end" can be manually set to 100°C on the main program...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com