Dam flow channel maintenance platform

A technology for overhauling platforms and runners, which is applied in the field of machinery, can solve the problems of quality damage to the bottom plate of the runner, consume a lot of manpower, financial resources, and increase maintenance costs, etc., and achieve good operation adaptability, improved safety and reliability, and convenient assembly and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

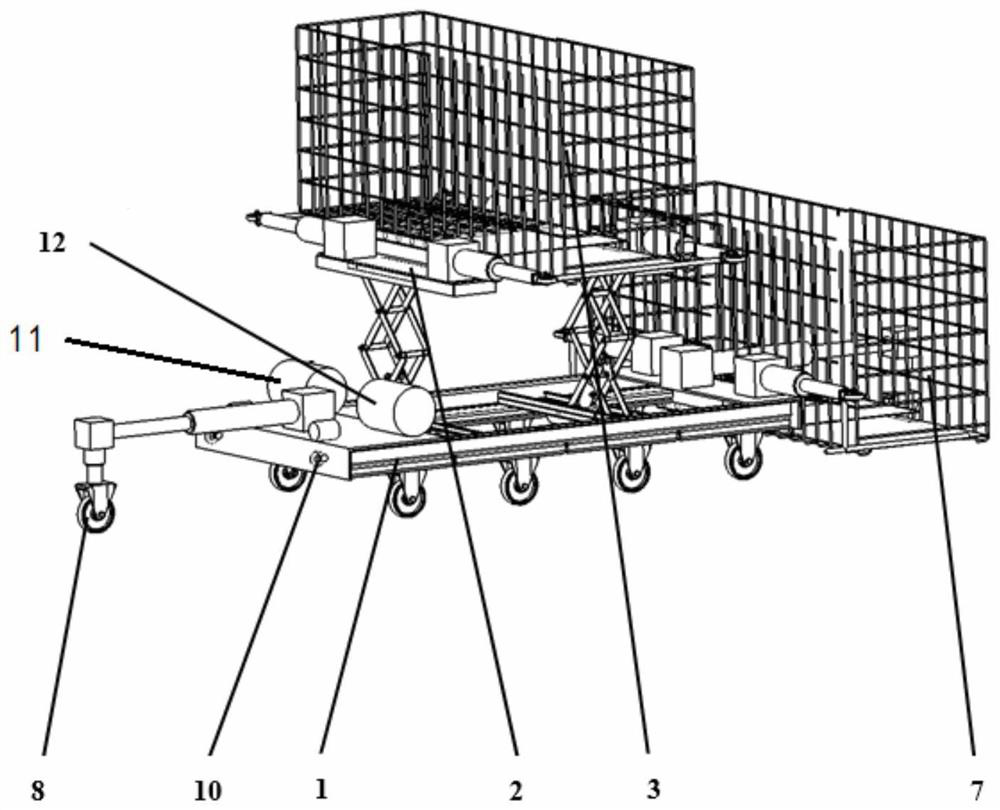

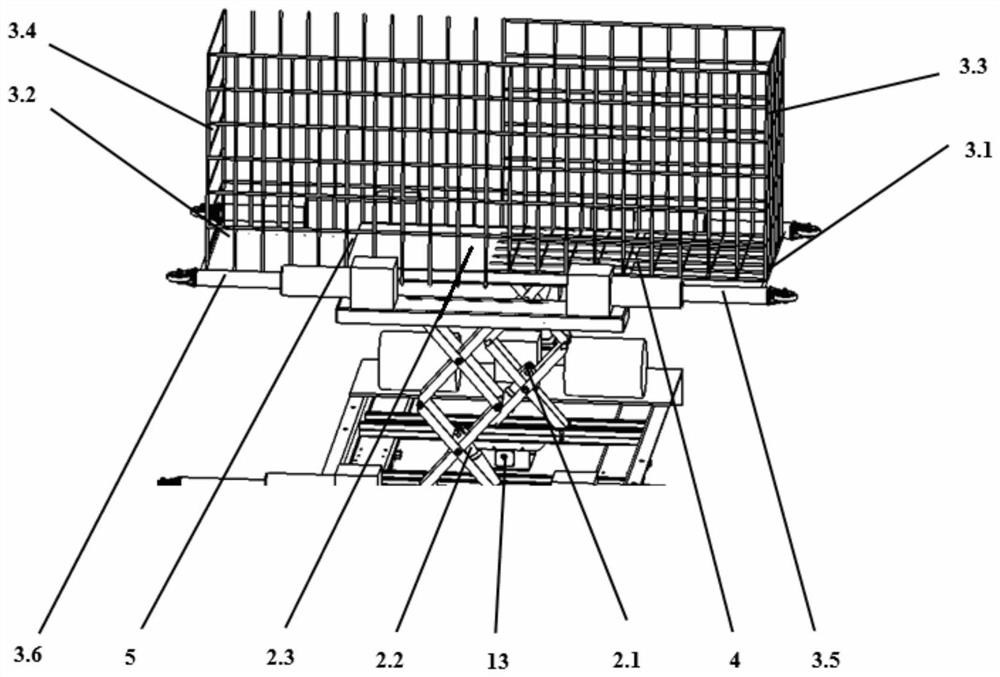

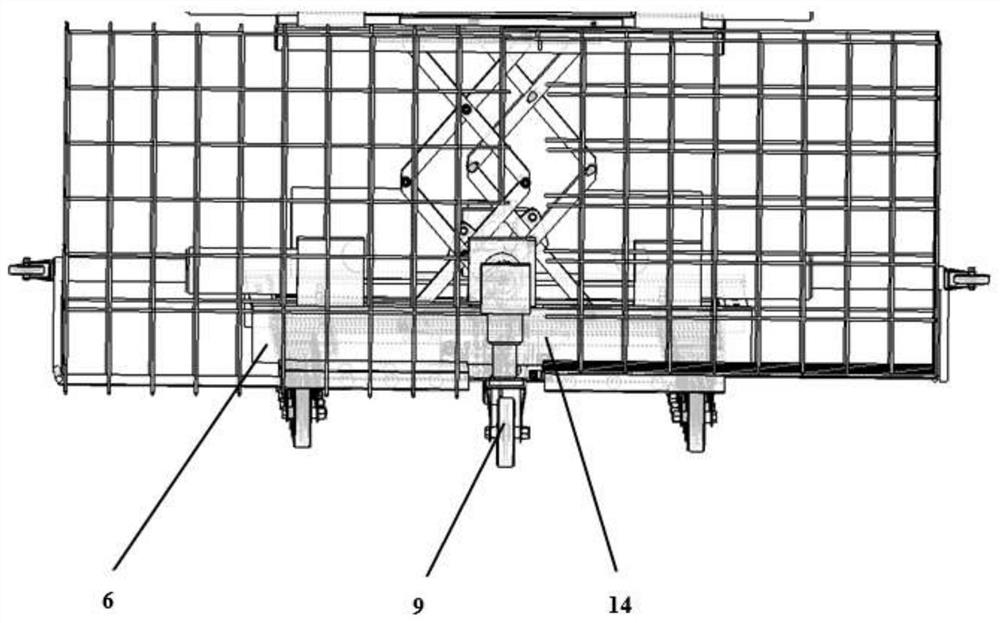

[0024] Below in conjunction with accompanying drawing, the present invention will be further explained:

[0025] see figure 1 The bottom of the vehicle frame 1 is provided with wheels, and the middle part of the vehicle frame 1 is provided with a self-balancing lifting platform 2, and the self-balancing lifting platform 2 includes a front elevator 2.1 fixed on the vehicle frame 1 at the bottom, a rear elevator 2.2, and two elevators. The supported lifting platform 2.3 is provided with an attitude sensor 13 for detecting the horizontal state of the lifting platform on the lifting platform 2.3; see figure 2 , the front telescopic work basket 3 is provided on the lifting platform 2.3, and the front telescopic work basket includes two left and right telescopic bottom plates 3.1, 3.2, and the left and right two telescopic bottom plates 3.1, 3.2 correspondingly fixed on the left and right , two telescopic basket frames 3.3, 3.4 on the right, and two sets of tension arms 3.5, 3.6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com