A New Type of Grinding and Forming Device for Biopharmaceutical Tablets

A biopharmaceutical and molding device technology, applied in the field of medical devices, can solve problems such as fragmentation, extrusion molds, labor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

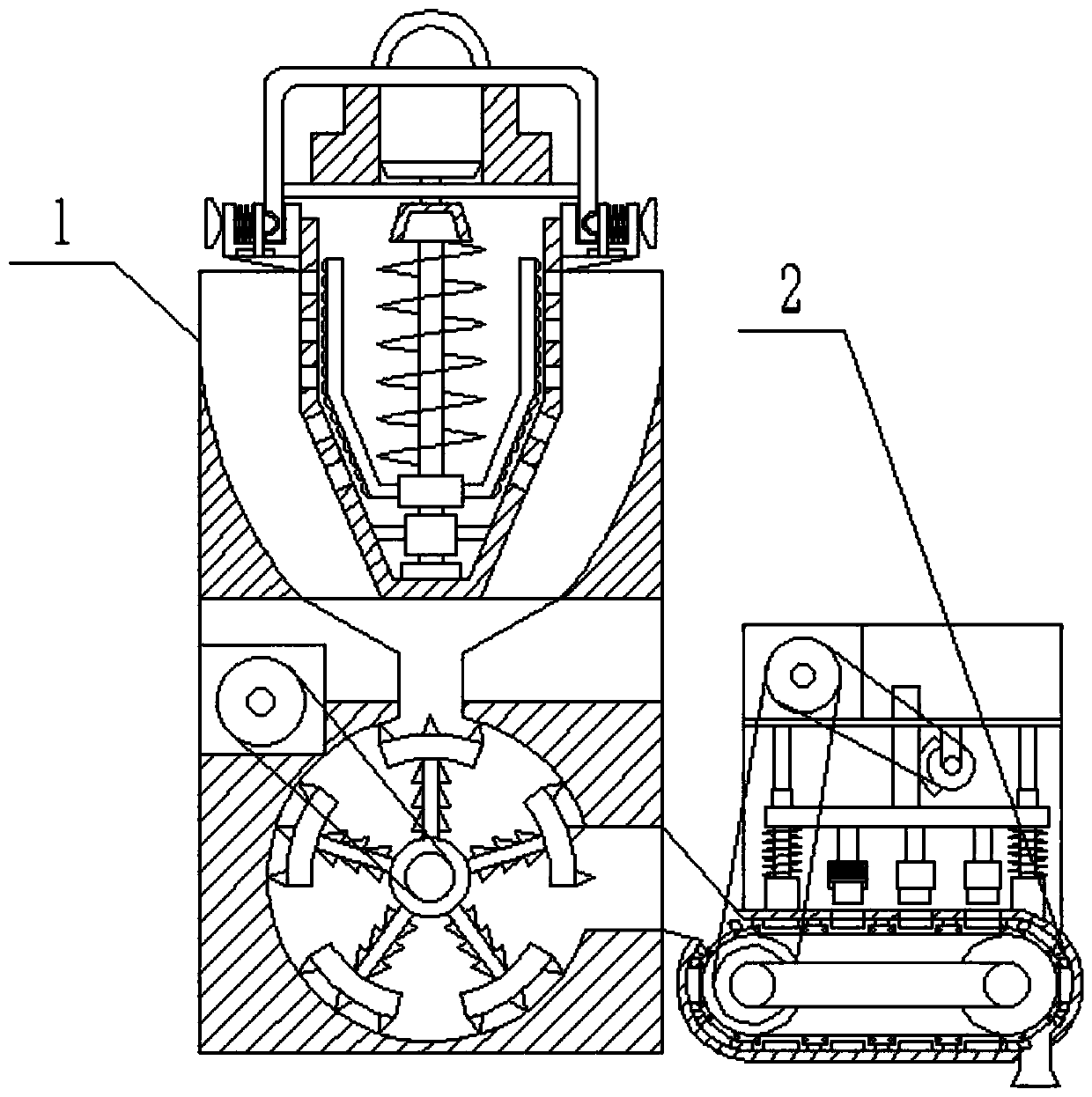

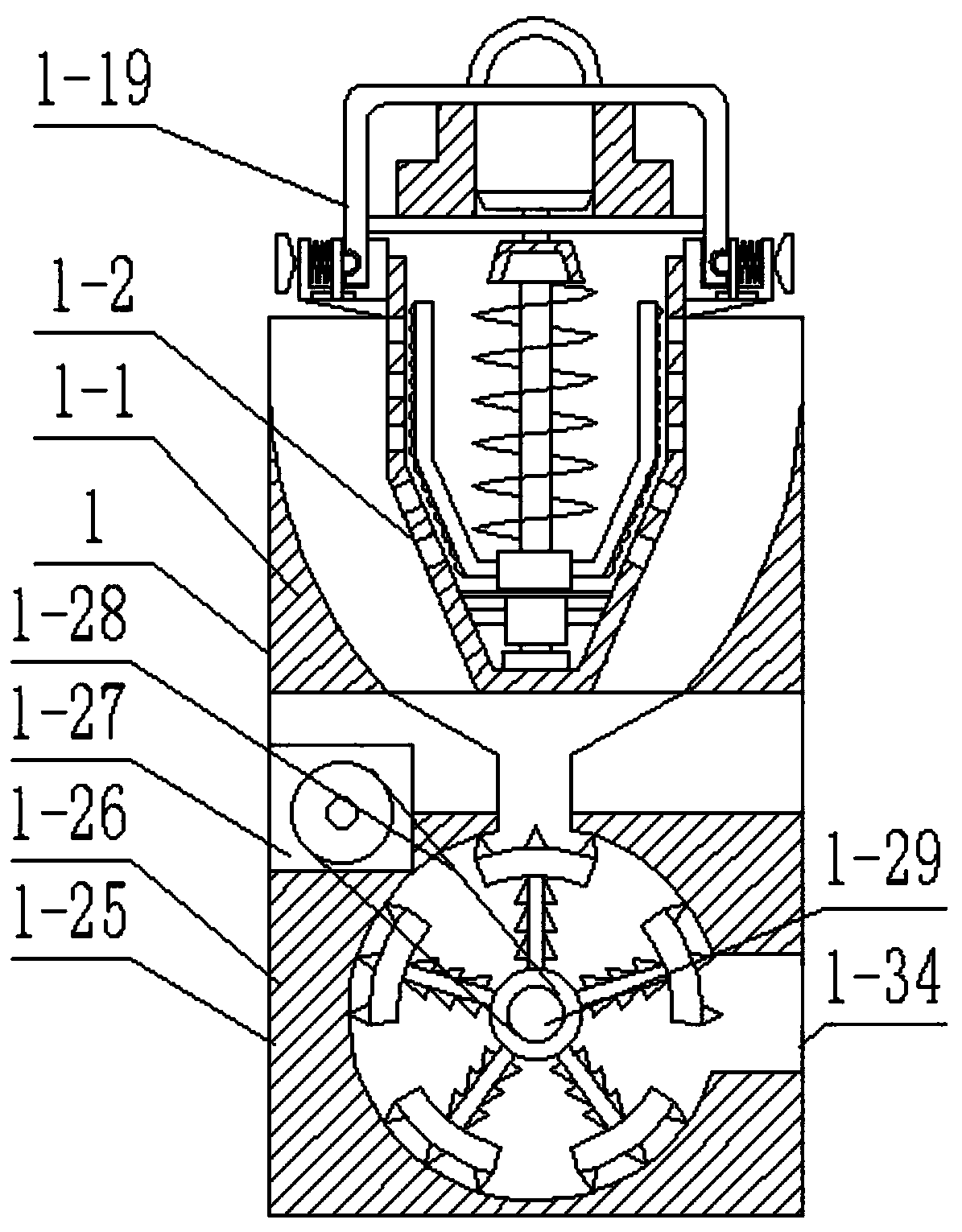

[0029] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12 illustrate this embodiment. The present invention relates to a medical device, more specifically a new type of biopharmaceutical tablet grinding and forming device, including Grinding box base 1 and forming box 2 can solve the problem that punching tablets is a common method in pharmaceutical production in biopharmaceuticals. Tablets need to be ground, mixed and transported before punching. It can solve the problem that the tablets supported by the existing stamping equipment for single-time stamping and stamping are easy to be stamped incorrectly and cause fragmentation, and the problem that the pharmaceutical powder in the mold is easy to be extruded from the mold by one-time stamping.

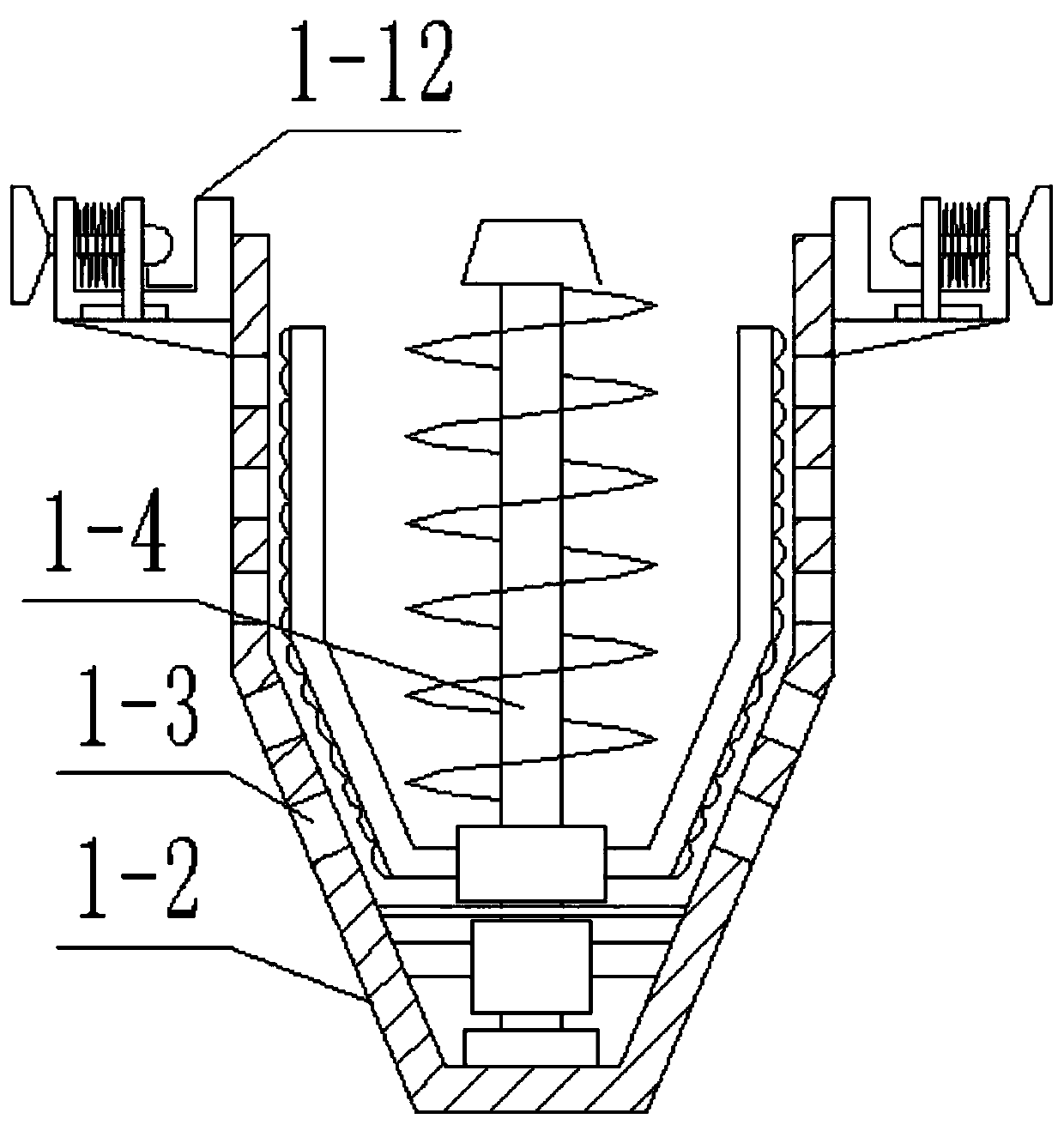

[0030] Grinding box base 1 is provided with grinding box base limit block 1-1, grinding box 1-2, grinding box discharge hole 1-3, grinding box rotating shaft 1-4, grinding box spiral fan blade 1-5 , grinding box rotati...

specific Embodiment approach 2

[0034] Combine below figure 1 , 2 . 4. Grinding box spiral fan blade 1-5, grinding box rotating shaft bevel gear 1-6, grinding box anti-sticking arm rotating sleeve 1-7, grinding box anti-sticking arm 1-8, grinding box rotating shaft supporting sleeve 1-10 common center line.

specific Embodiment approach 3

[0036] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 illustrate this embodiment, and this embodiment will further explain Embodiment 1, the grinding box base 1, the grinding box anti-adhesive strip 1-9 common center line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com