Self-tightening bolt and self-tightening stud

A bolt and stud technology, applied in the field of general machinery, can solve the problems of loose bolts and nuts, affecting work efficiency, waste and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0084] According to a first embodiment of the present invention, a self-tightening bolt is provided:

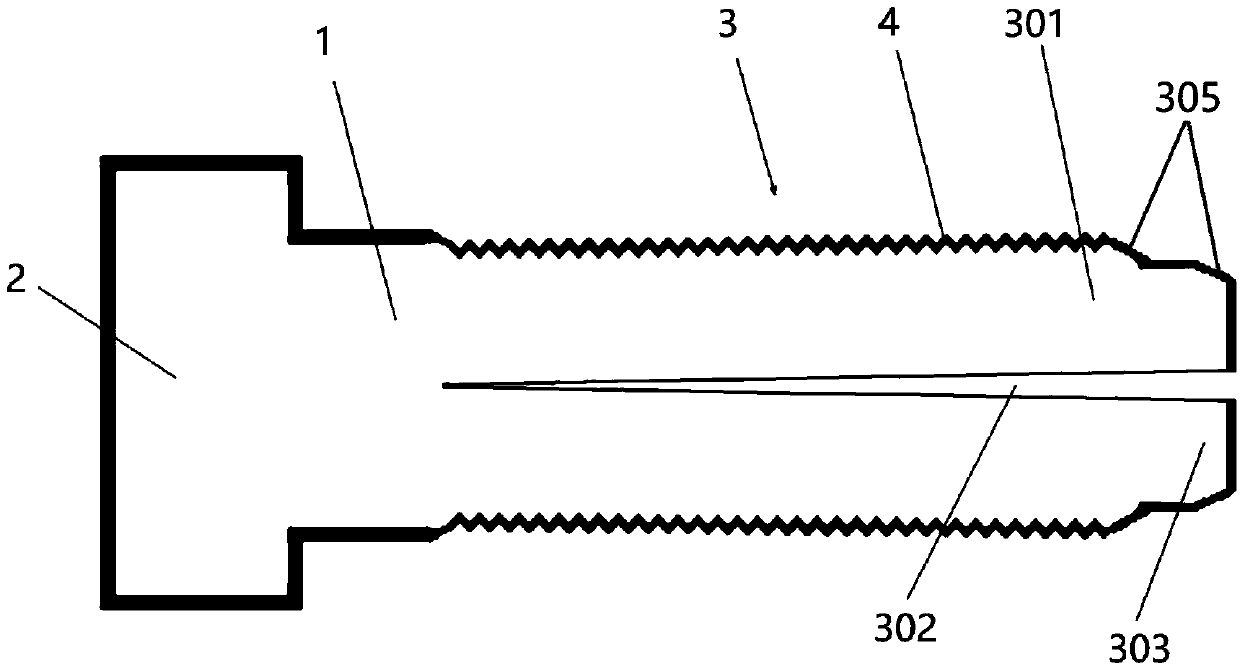

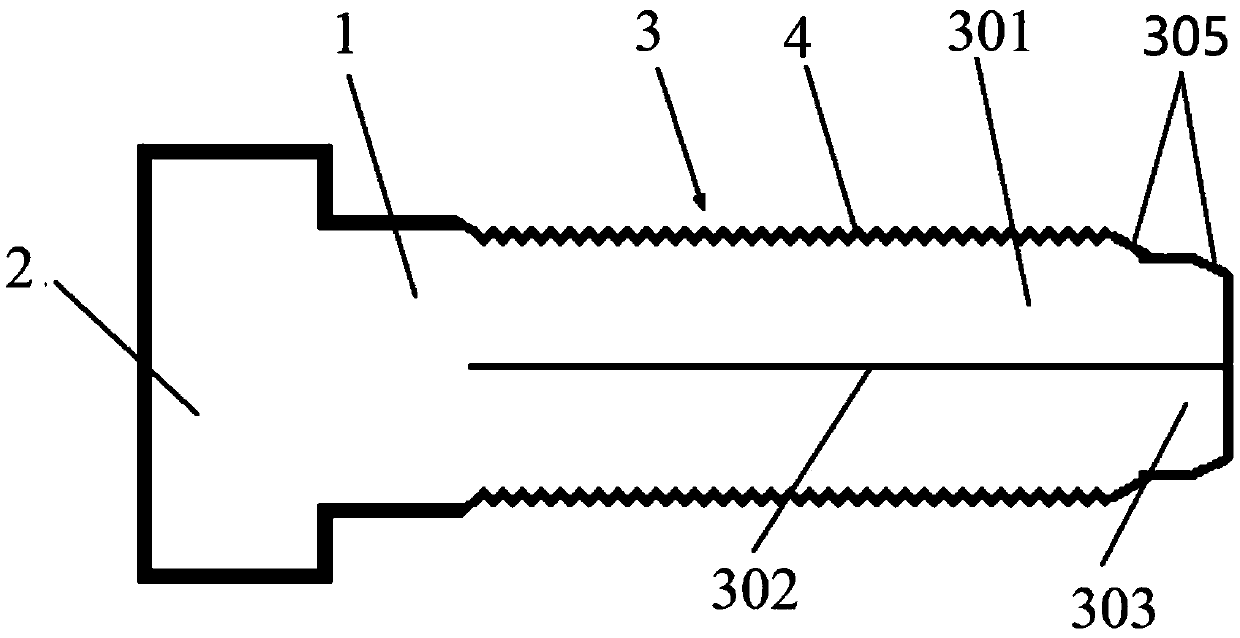

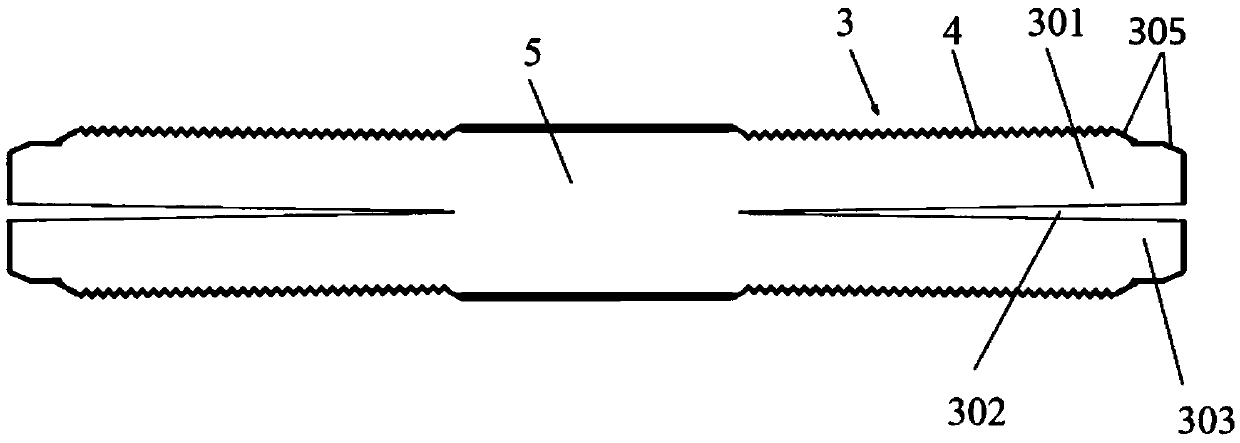

[0085] A self-tightening bolt, the self-tightening bolt includes: a bolt body 1, a bolt head 2, a tightening part 3, and a thread structure 4; the bolt head 2 is arranged at one end of the bolt body 1; the tightening part 3 is arranged at The other end of the bolt main body 1; the threaded structure 4 is arranged on the outer surface of the tightening part 3; the tightening part 3 includes: a warping body 301, a deformation pretension seam 302; the tightening part 3 is composed of the The deformation pretension seam 302 separates a plurality of warping bodies 301; the outer circumference of the warping bodies 301 is provided with a thread structure 4; the parts of the warping bodies 301 close to the end of the bolt head 2 are closely attached to each other; The part of the warping body 301 away from the end of the bolt head 2 is separated from each other; the diameter of the ...

Embodiment 1

[0109] A self-tightening bolt, the self-tightening bolt includes: a bolt body 1, a bolt head 2, a tightening part 3, and a thread structure 4; the bolt head 2 is arranged at one end of the bolt body 1; the tightening part 3 is arranged at The other end of the bolt main body 1; the threaded structure 4 is arranged on the outer surface of the tightening part 3; the tightening part 3 includes: a warping body 301, a deformation pretension seam 302; the tightening part 3 is composed of the The deformation pretension seam 302 separates a plurality of warping bodies 301; the outer circumference of the warping bodies 301 is provided with a thread structure 4; the parts of the warping bodies 301 close to the end of the bolt head 2 are closely attached to each other; The part of the warping body 301 away from the end of the bolt head 2 is separated from each other; the diameter of the thread structure 4 on the side of the warping body 301 close to the end of the bolt head 2 is D1, and th...

Embodiment 2

[0111] Repeat Example 1, except that the tightening part 3 also includes: the installation guide head 303, the installation guide head 303 is arranged on the end surface of the tightening part 3; the installation guide head 303 is coaxial with the tightening part 3; the installation guide head 303 and the The connected warping body 301 is separated by the deformation pretension seam 302; the diameter of the installation guide head 303 after separation is D5; D5≤D1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com