Self-locking bolt or stud and nut fastening device

A fastening device and nut technology, applied in the field of fastening devices, bolts, nut fastening devices, nut fastening devices or self-tightening studs, can solve the problems of loose bolts and nuts, affecting work efficiency, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

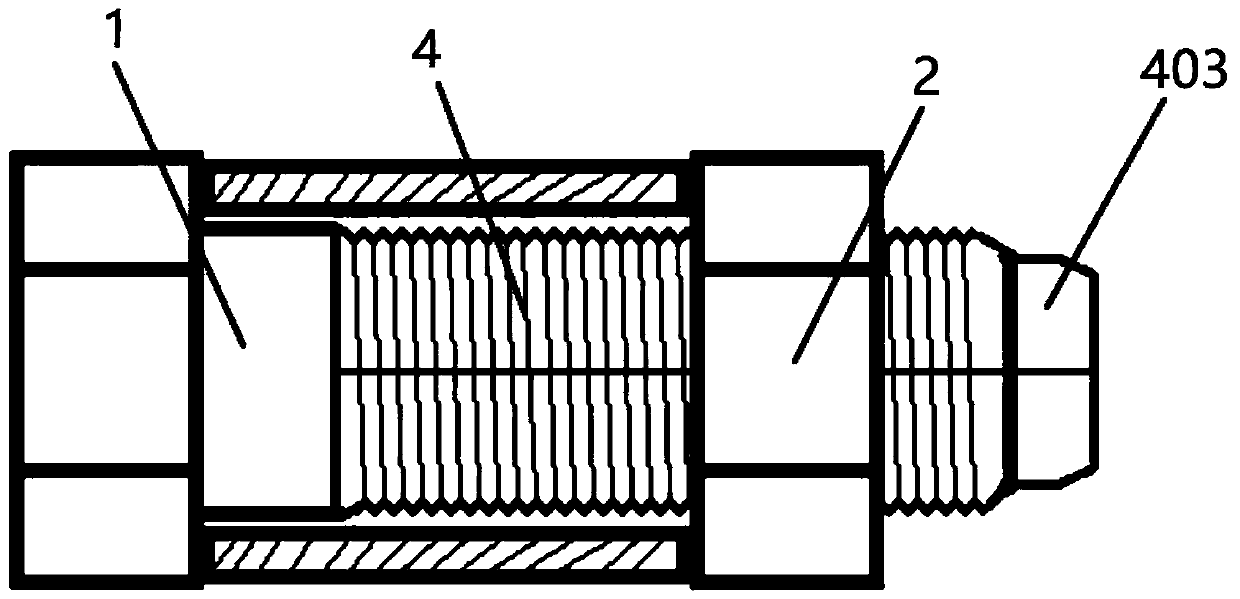

[0102] According to a first embodiment of the present invention, a self-tightening bolt and nut fastening device is provided:

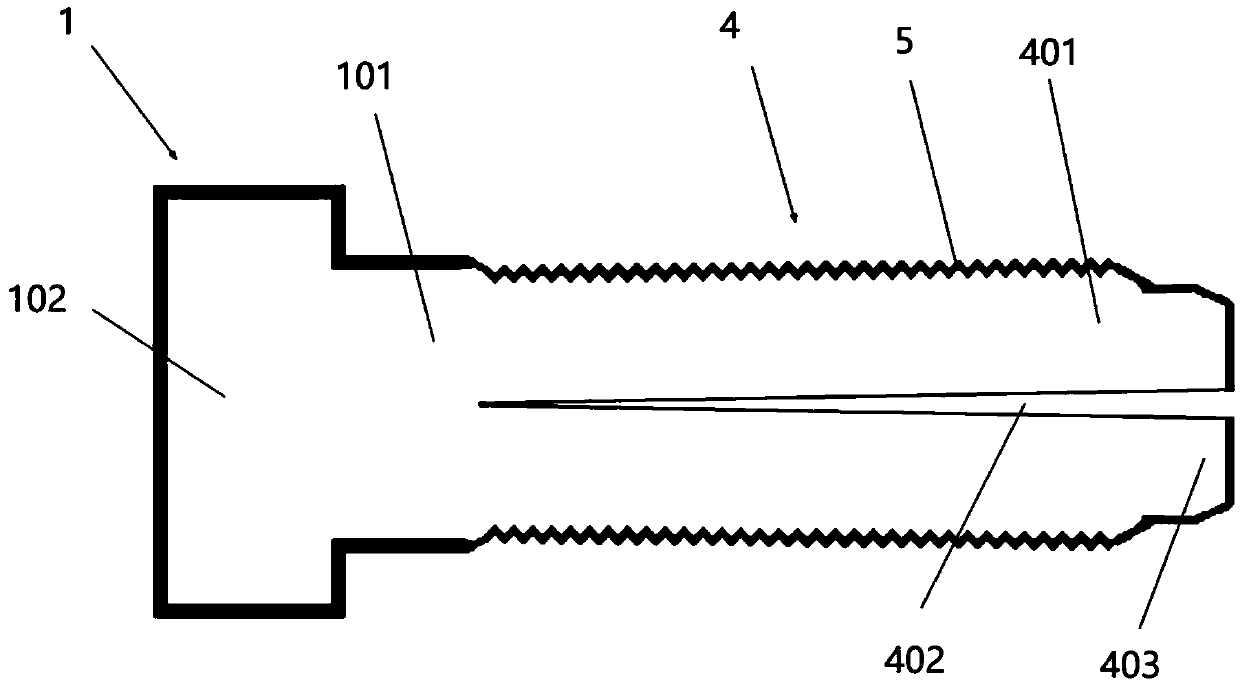

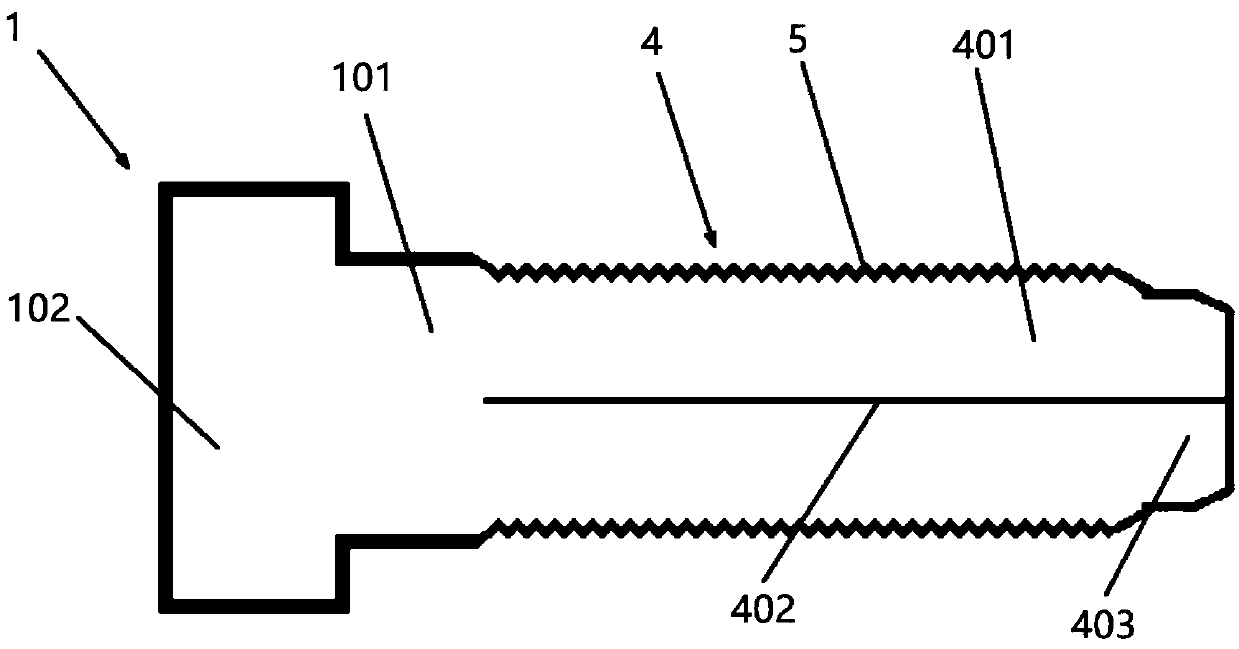

[0103] A self-tightening bolt and nut fastening device, the device includes: a bolt 1, a nut 2; the nut 2 is assembled with the bolt 1 through a threaded structure; the bolt 1 includes: a bolt body 101, a bolt head 102, a tightening Part 4, external thread structure 5; the bolt head 102 is arranged at one end of the bolt body 101; the tightening part 4 is arranged at the other end of the bolt body 101; the external thread structure 5 is arranged at the tightening part 4 The outer surface of the nut 2 includes: a nut body 201, a nut through hole 202, and an internal thread structure 203; the nut through hole 202 is disposed on the nut body 201; the internal thread structure 203 is disposed on the On the inner wall of the nut through hole 202; the tightening part 4 includes: a warping body 401 and a deformation pretension seam 402; the tightening part 4...

Embodiment 1

[0131] A self-tightening bolt and nut fastening device, the device includes: a bolt 1, a nut 2; the nut 2 is assembled with the bolt 1 through a threaded structure; the bolt 1 includes: a bolt body 101, a bolt head 102, a tightening Part 4, external thread structure 5; the bolt head 102 is arranged at one end of the bolt body 101; the tightening part 4 is arranged at the other end of the bolt body 101; the external thread structure 5 is arranged at the tightening part 4 The outer surface of the nut 2 includes: a nut body 201, a nut through hole 202, and an internal thread structure 203; the nut through hole 202 is disposed on the nut body 201; the internal thread structure 203 is disposed on the On the inner wall of the nut through hole 202; the tightening part 4 includes: a warping body 401 and a deformation pretension seam 402; the tightening part 4 is divided into a plurality of warping bodies 401 by the deformation pretension seam 402; The outer circumference of the warpin...

Embodiment 2

[0133] Repeat Example 1, except that the internal diameter of one end of the internal thread structure 203 is D5, and the internal diameter of the other end of the internal thread structure 203 is D6; and D5>D6; the internal diameter of the internal thread structure 203 is from D5 at one end to the other end The D6 gradually becomes smaller and excessive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com