A dual-fuel direct injection injector for vehicles

A dual-fuel and fuel injector technology, applied in fuel injection devices, charging systems, machines/engines, etc., can solve problems such as increased cost, increased control difficulty, and limited layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

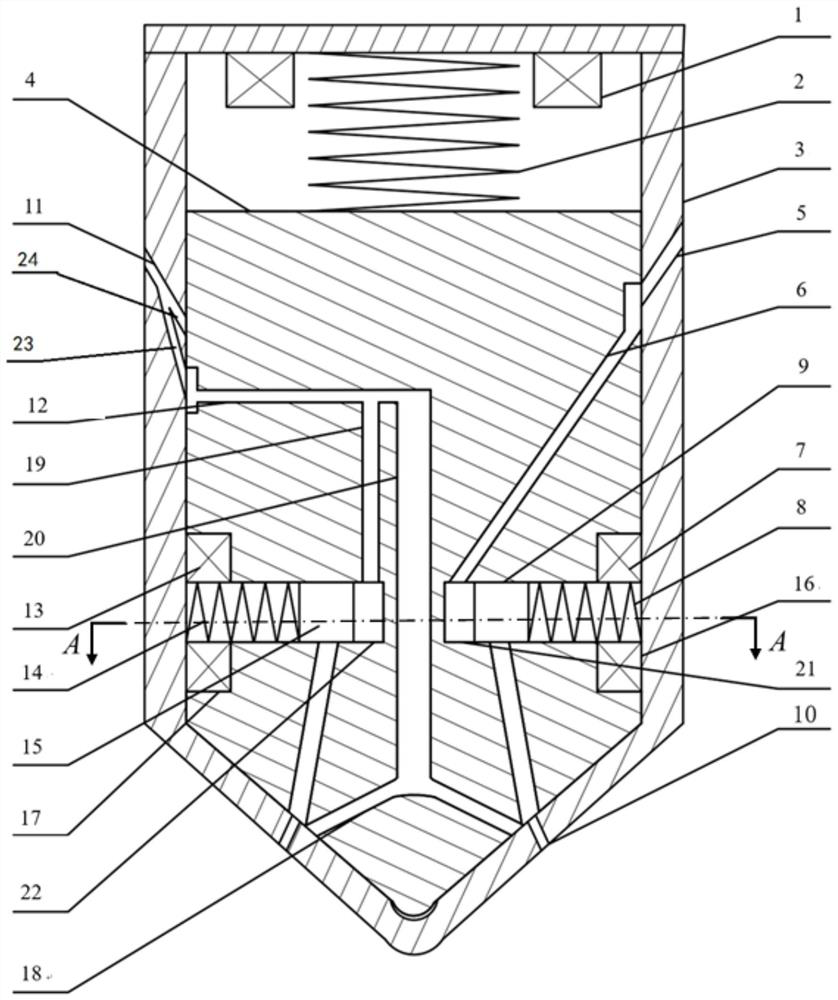

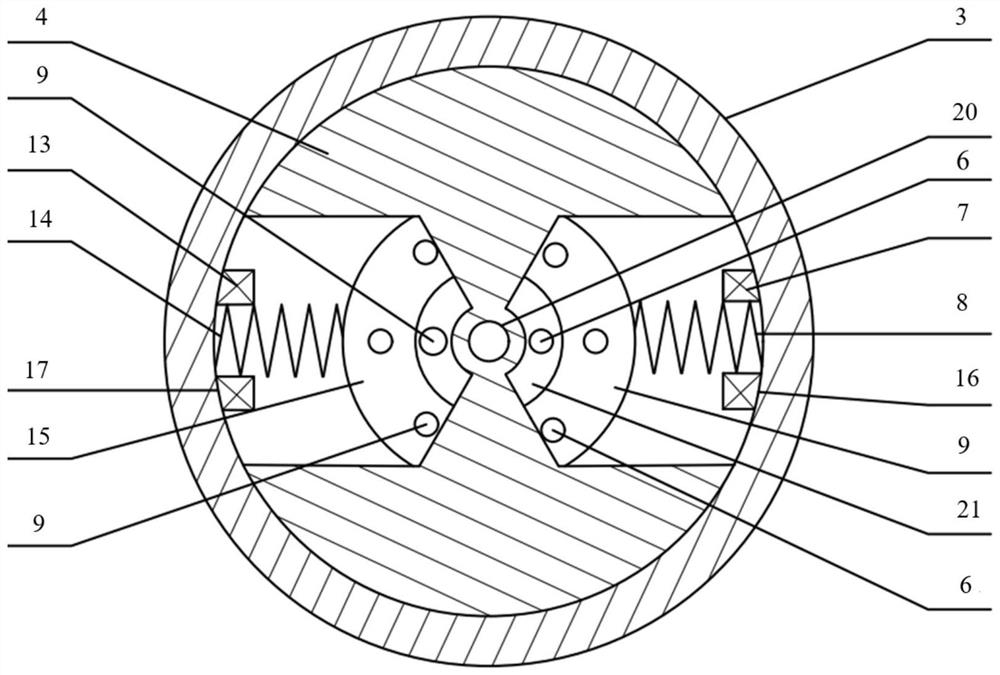

[0037] A dual-fuel direct injection fuel injector for vehicles, such as Figure 1-2 shown, including:

[0038]The injector body 3, and the main valve core 4 which is arranged inside the injector body 3 and can move up and down along the axis of the injector body 3; the first fuel inlet 5 is located at one side of the upper part of the injector body 3, and the second fuel inlet 11 is located at On the other side opposite to the upper part of the injector body 3, its end is branched up and down in a Y shape; the injection hole 10 is located at the bottom of the injector body 3; the first fuel passage 6 and the second fuel passage are arranged inside the main valve core 4, respectively One side of the first fuel inlet 5 and the second fuel inlet 11, the second fuel passage is divided into a second fuel passage front section 12 and a second fuel passage rear section 19, and the second fuel passage front section 12 leads out from the second fuel passage rear section. 19 parallel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com