Method for grinding plane of bearing ring

A technology for surface grinding and bearing rings, which is applied in the field of bearing processing, can solve the problems of limited improvement of surface quality and inability to improve flatness errors, and achieve the effect of reducing working steps and reducing flatness errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

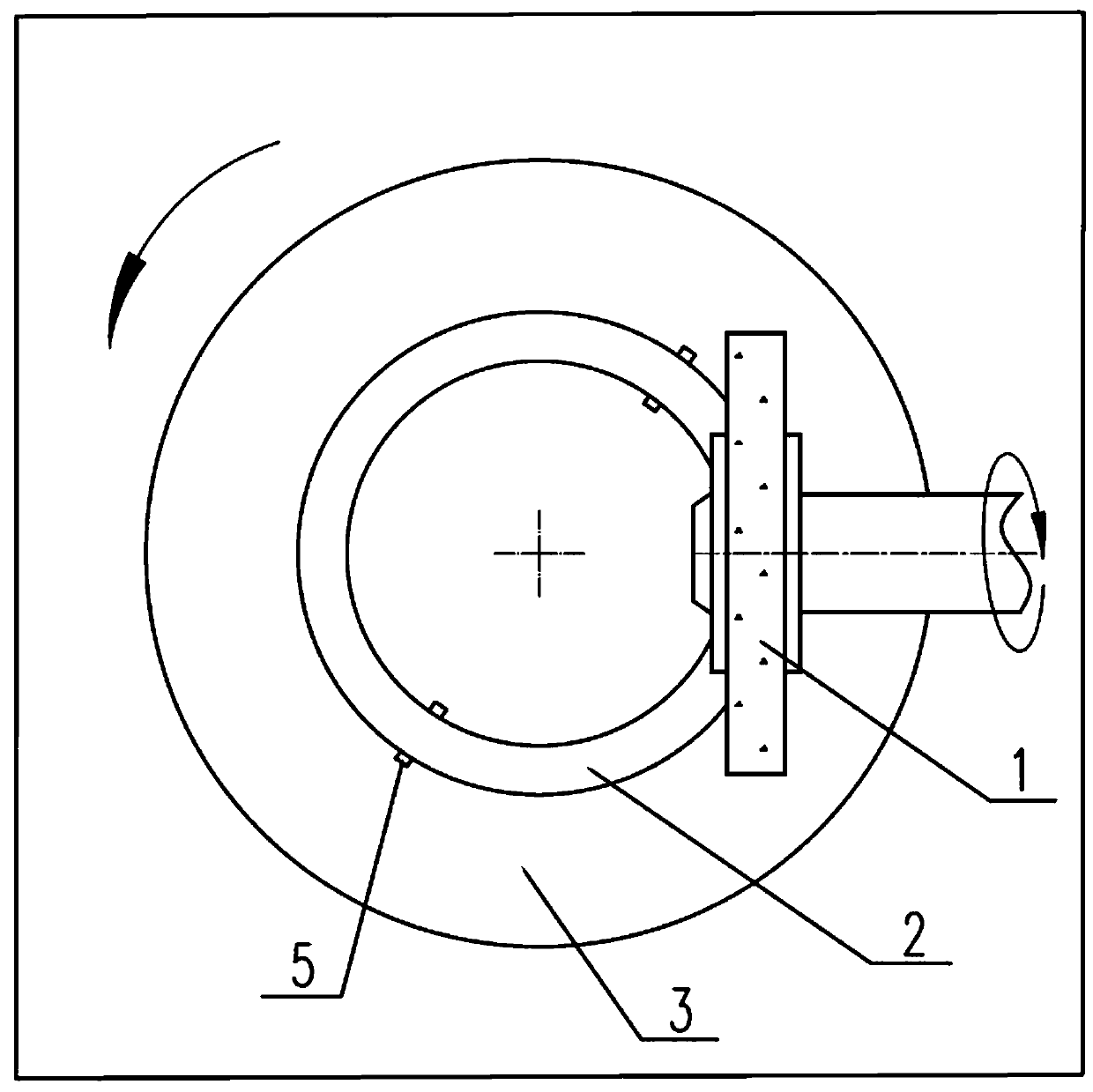

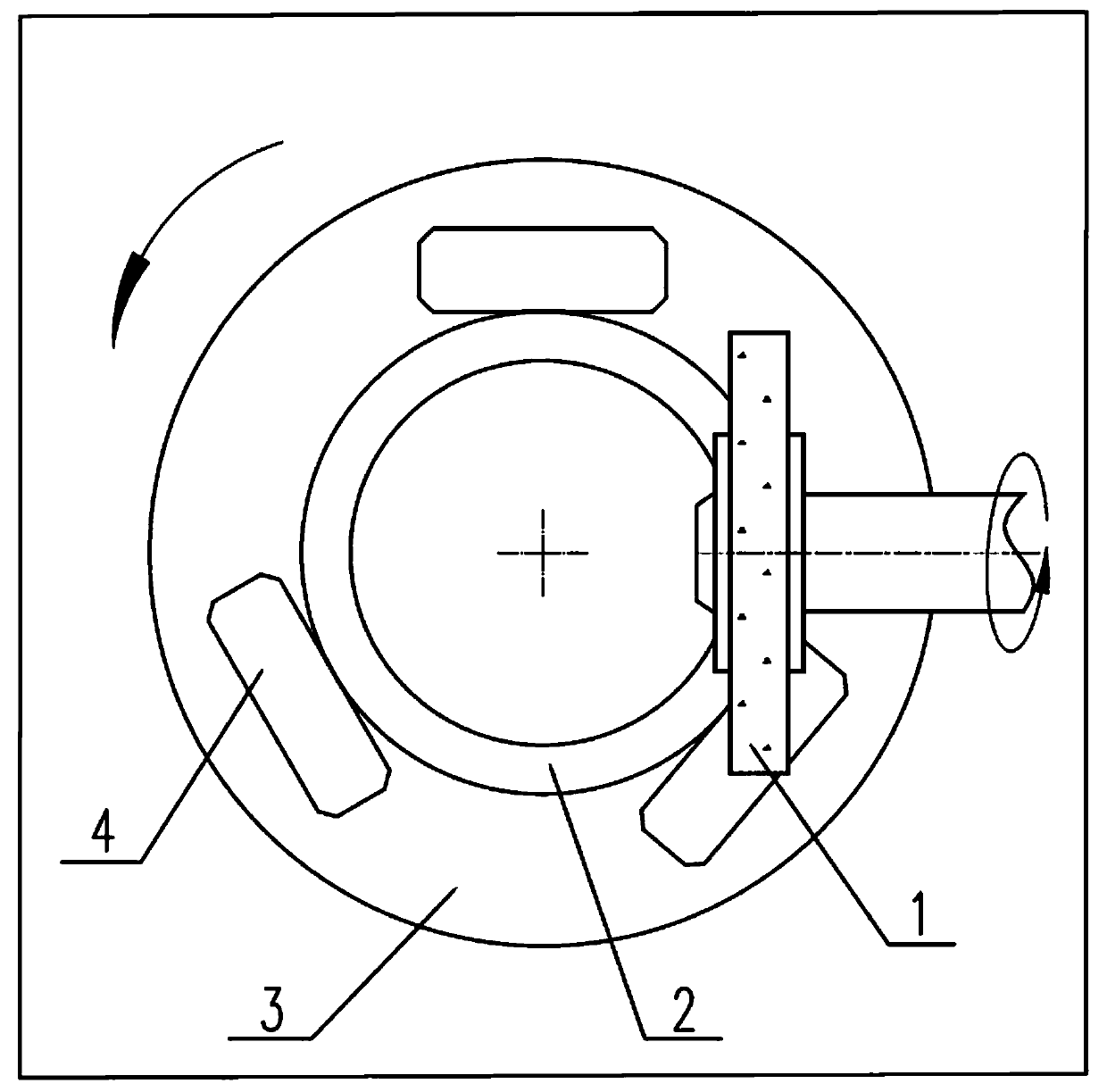

Method used

Image

Examples

Embodiment 1

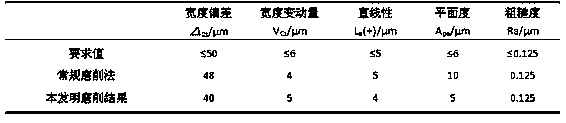

[0027] The invention is applied to the surface finish grinding of 01 parts and 22 parts of large thin-walled bearings YRT460 / P4 bearings. Part material: GCr15SiMn, nominal sizes are Φ518×Φ600×22 and Φ560×Φ461×16; grinder model: MGK7363; parts accuracy requirements: width deviation ≤50, width variation ≤6, straightness ≤5, flatness ≤5 , Roughness≤0.125, unit: μm.

[0028] Take 20 finely ground parts of the above two parts, respectively use the conventional grinding method and the method of the present invention to grind 10 parts each of 01 and 22 parts. After the grinding is completed, the instrument is tested. The test results are shown in Table 1 and Table 2. When the flatness of the parts processed by conventional grinding is improved to about 10 μm, the flatness quality cannot be further improved, and the processing accuracy of the product is unqualified, and the accuracy of the parts processed by the invention meets the design requirements.

[0029] Table 1 YRT460 / P4.01 grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com