Corn thresher

A threshing machine and corn technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of corn grains being easily shot to the surrounding, easy to be sore, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

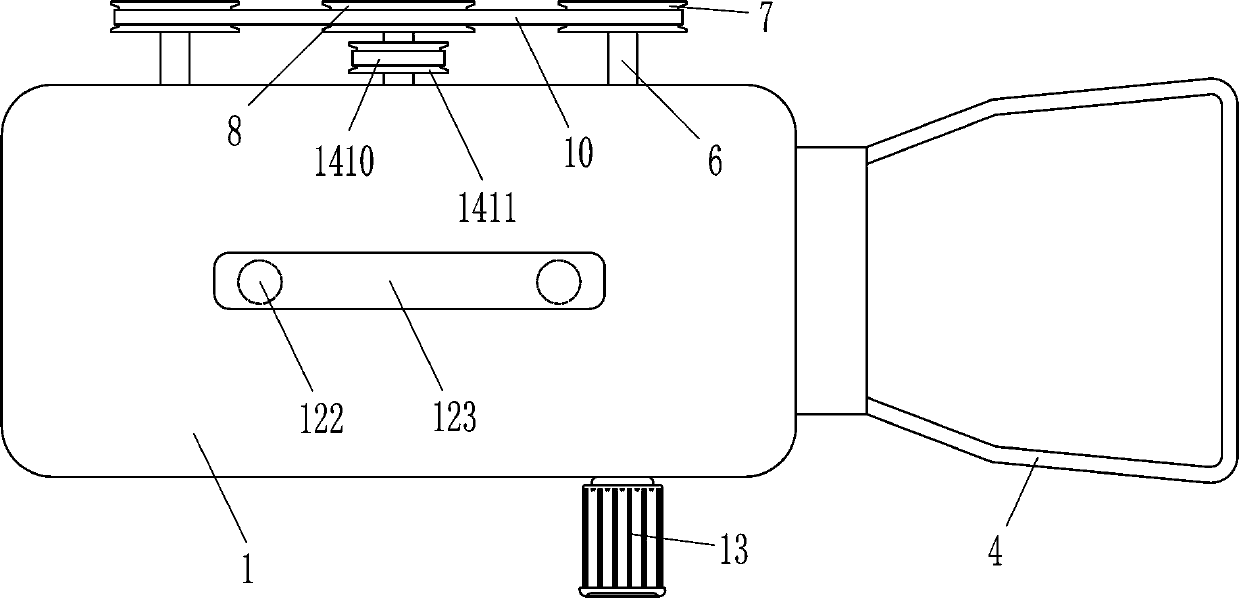

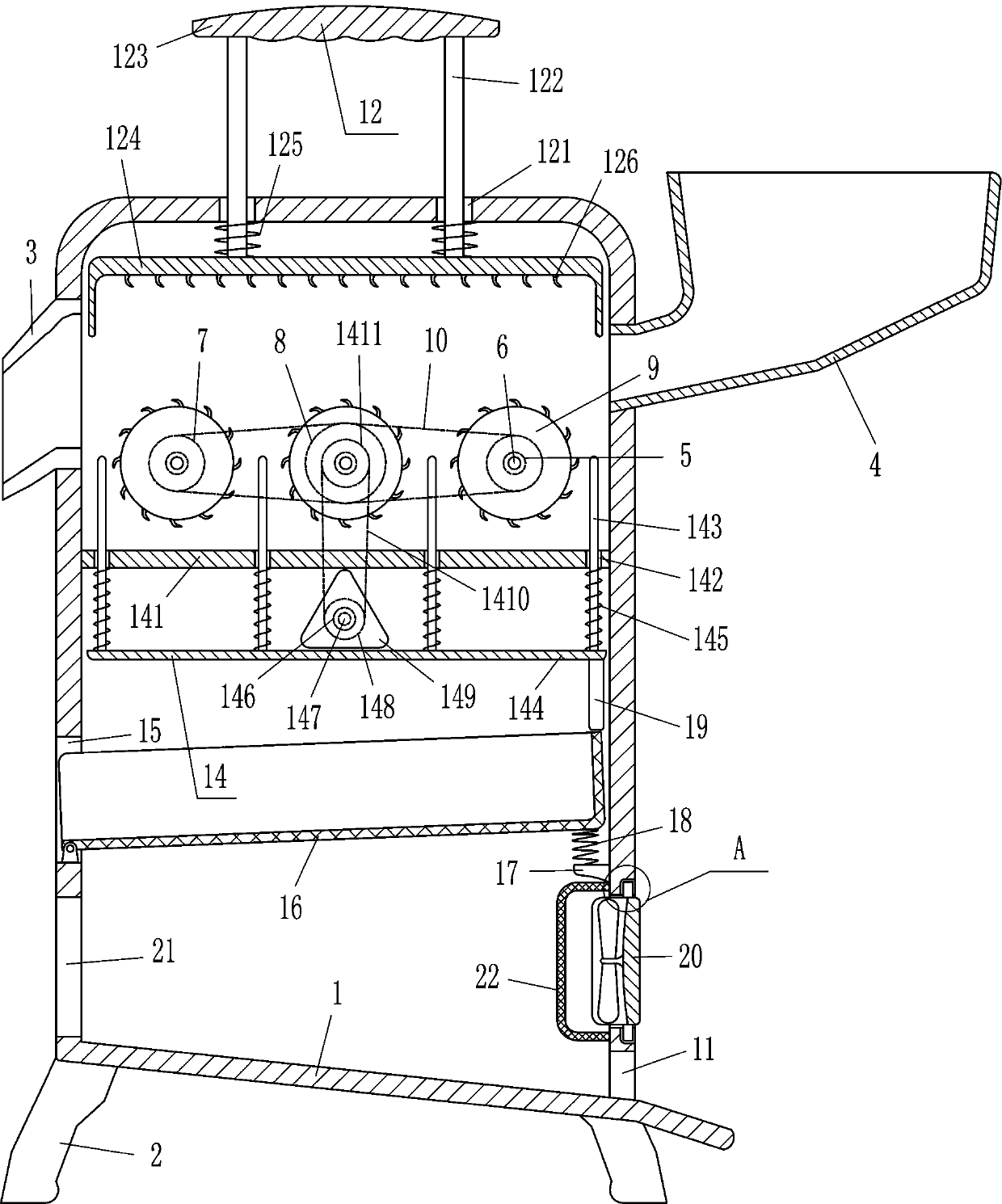

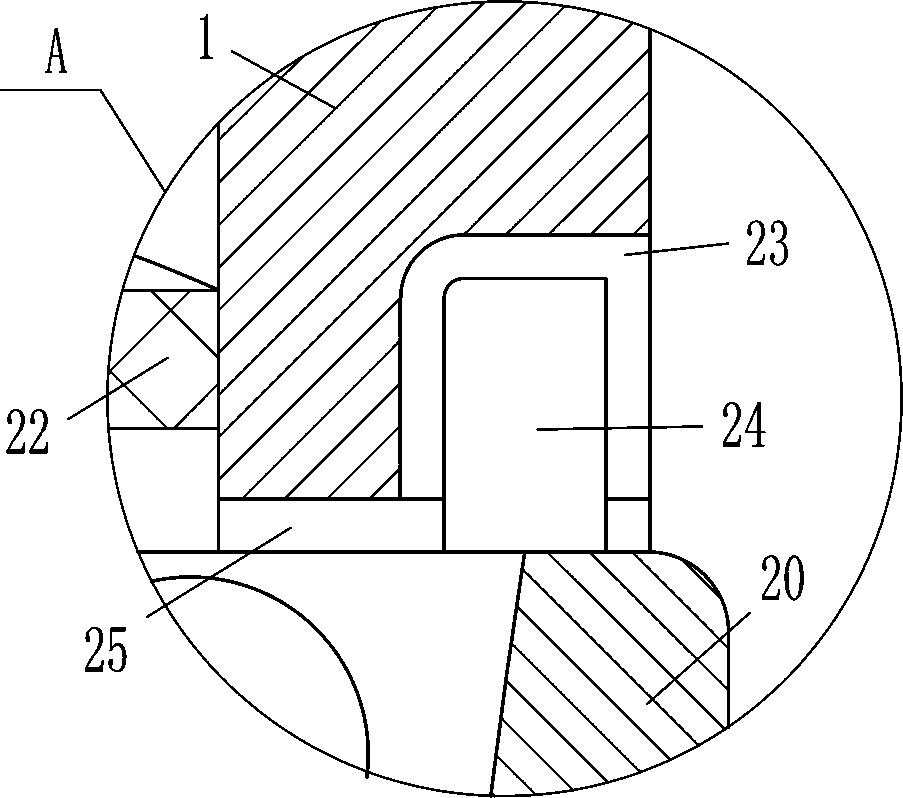

[0016] A corn thresher such as figure 1 As shown, it includes a box body 1, supporting legs 2, a hopper 3, a hopper 4, a first bearing seat 5, a first rotating shaft 6, a small pulley 7, a large pulley 8, a crushing wheel 9, and a first flat belt 10 , a limit device 12 and a drive motor 13, the outer bottom of the box body 1 is symmetrically fixed with legs 2 on the left and right sides, the box body 1 is connected to the legs 2 by bolts, and the upper left side of the box body 1 is installed with The discharge hopper 3 that can make the corn cobs drop, the discharge hopper 3 is connected with the inside of the box body 1, the feed hopper 4 that can make the corn pour into is installed on the upper right side of the box body 1, and the feed hopper 4 is connected with the box body by bolts. The box body 1 is connected, the feed hopper 4 communicates with the box body 1, and the lower part of the right side of the box body 1 has a discharge port 11 that can discharge the corn ke...

Embodiment 2

[0018] A corn thresher such as figure 1 As shown, it includes a box body 1, supporting legs 2, a hopper 3, a hopper 4, a first bearing seat 5, a first rotating shaft 6, a small pulley 7, a large pulley 8, a crushing wheel 9, and a first flat belt 10 , limit device 12 and driving motor 13, the left and right sides of the outer bottom of the box body 1 are fixedly connected with outriggers 2 symmetrically, and the upper left side of the box body 1 is equipped with a discharge hopper 3 that can make corn cobs fall, and the discharge hopper 3 It communicates with the inside of the box body 1, and the feed hopper 4 that can pour corn into it is installed on the upper right side of the box body 1. Three first bearing seats 5 are evenly spaced on the top of the front and rear sides of the box body 1, and the first rotating shaft 6 is connected with the bearings in the first bearing seats 5 on the front and rear sides. The rear end of the rotating shaft 6 is fixedly connected with a ...

Embodiment 3

[0021] A corn thresher such as Figure 1-2As shown, it includes a box body 1, supporting legs 2, a hopper 3, a hopper 4, a first bearing seat 5, a first rotating shaft 6, a small pulley 7, a large pulley 8, a crushing wheel 9, and a first flat belt 10 , limit device 12 and driving motor 13, the left and right sides of the outer bottom of the box body 1 are fixedly connected with outriggers 2 symmetrically, and the upper left side of the box body 1 is equipped with a discharge hopper 3 that can make corn cobs fall, and the discharge hopper 3 It communicates with the inside of the box body 1, and the feed hopper 4 that can pour corn into it is installed on the upper right side of the box body 1. Three first bearing seats 5 are evenly spaced on the top of the front and rear sides of the box body 1, and the first rotating shaft 6 is connected with the bearings in the first bearing seats 5 on the front and rear sides. The rear end of the rotating shaft 6 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com