Threshing method of food processing thresher

A food processing and thresher technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as incomplete threshing, and achieve the effect of compact structure and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

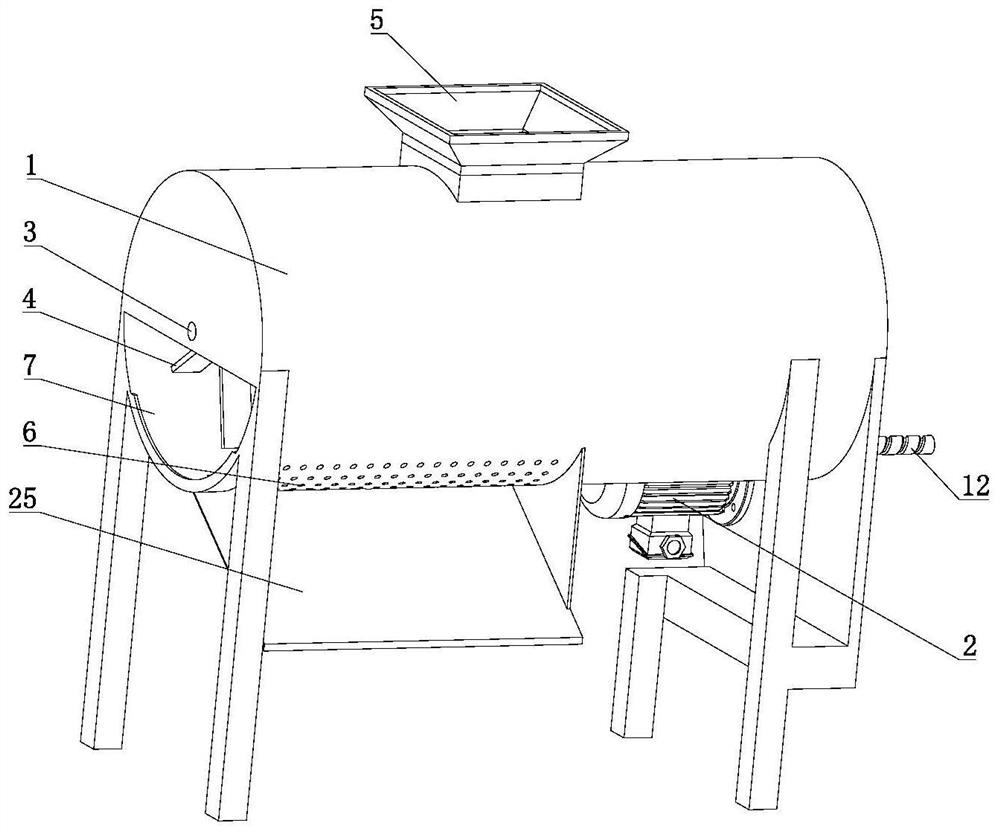

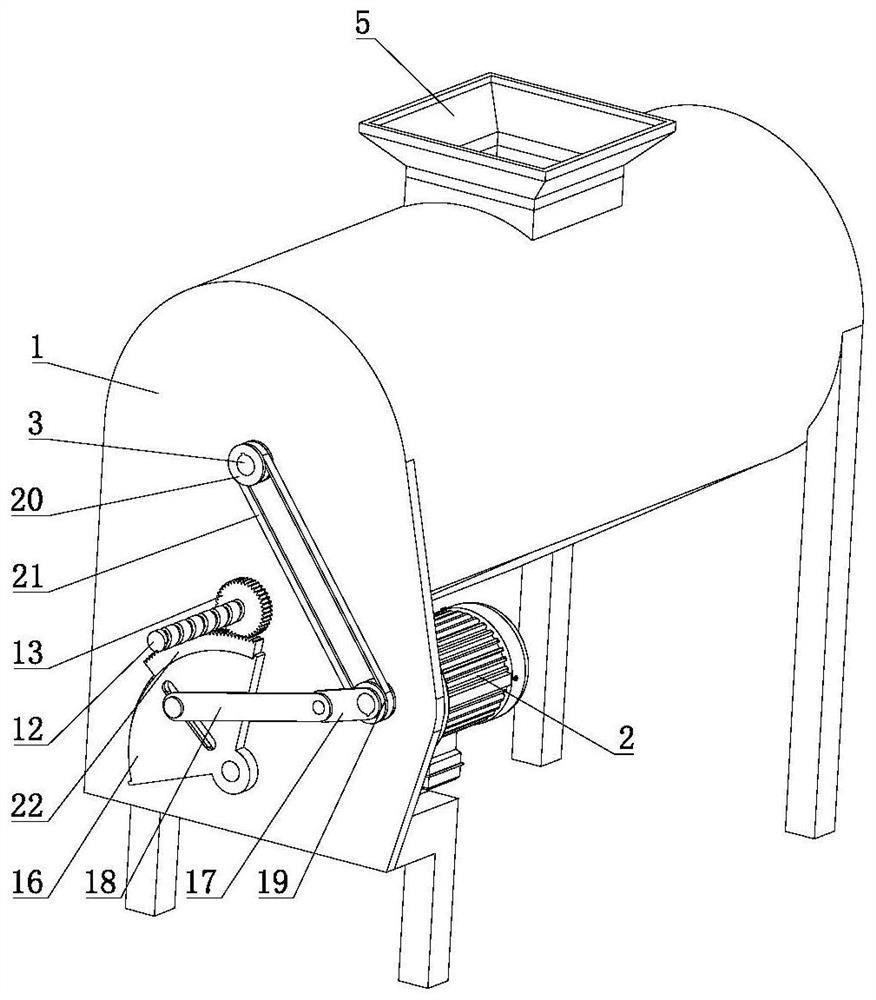

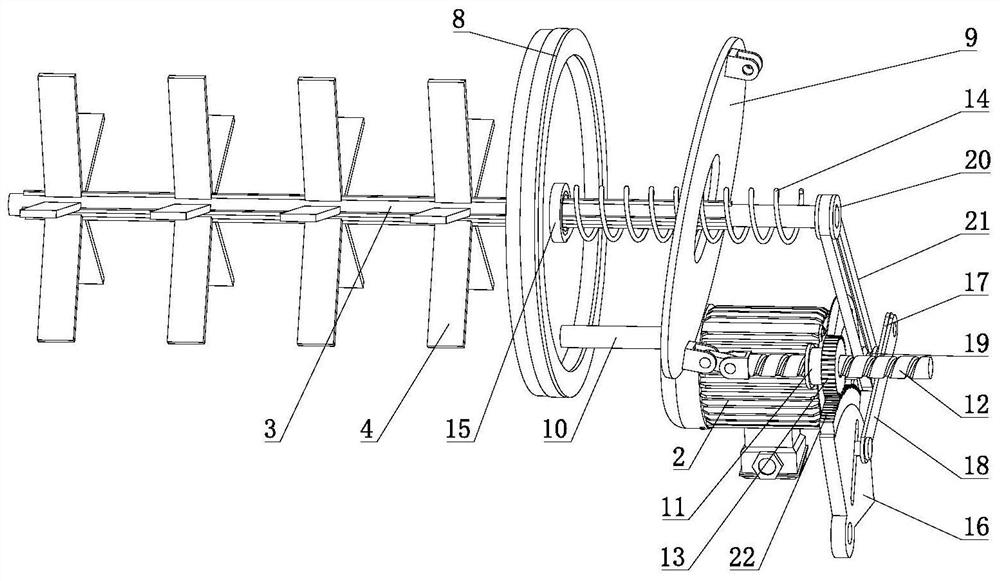

[0028] Example 1: Such as Figure 1 to 4 As shown, the thorn machine of the present embodiment is used for food processing, which includes a barrel 1 and a threshing mechanism located within the barrel 1, and the motor 2 is provided on the cartridge 1, and the thilled mechanism includes a thres axis 3 and a number of degraded rods 4. The thorn shaft 3 is rotatably rotated on the barrel 1, and several dry rods 4 are fixed to the thiring shaft 3, the thissated shaft 3 is driven by the motor 2, and the motor 2 is rotated by the thilled shaft 3 and the plurality of thus rod 4 rotates to achieve the pending operation. This part of the structure is no further detailed in the conventional mechanism, so that foods containing food grains such as corn, cereals and fruits can be taken, and the food grain of the food is separated from the food body, classify the food grain and food body.

[0029] The head and the bottom of the cartridge 1 are respectively provided with the feed port 5 and the ...

Embodiment 2

[0034] Example 2: Different from Example 1, the thorn of the present embodiment Figure 5 to Figure 7 It also includes a discharge plate 26, which is hinged to the barrel 1 side for opening or closing the discharge port 7, and the inner wall of the barrel 1 is provided with a guide groove 27, and the pusher plate 8 is provided with a guide projection 28. The guide projection 28 is slidable with the guide groove 27, and the unit is inserted with a linkage rod 29. When one end of the linkage rod 29 is connected to the discharge plate 26, the other end of the linkage rod 29 extends into the guide groove. After 27, the push plate 8 is opened by pushing the linkage rod 29 by pushing the linkage rod 29, and the pusher plate 8 is turned off by pulling the linkage rod 29, the linkage rod 29 and the discharge plate There is a telescopic rod 31 with the reset spring 30, and one end of the telescopic rod 31 is rotated from the linkage rod 29, and the other end of the telescoping rod 31 is rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com