Intelligent fastener

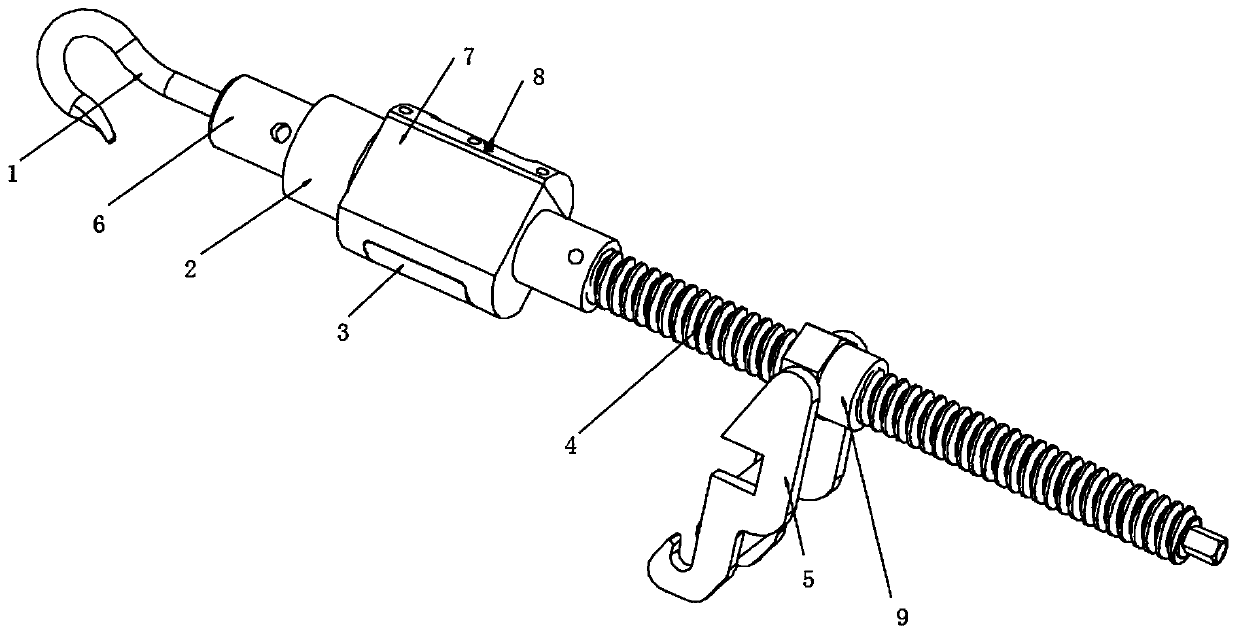

A fastener and intelligent technology, which is applied in the field of intelligent fasteners, can solve the problems of difficult to achieve all-round and real-time monitoring of the fastening state of fasteners, and it is difficult for inspection personnel to determine the fasteners, and achieve intelligent effect of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

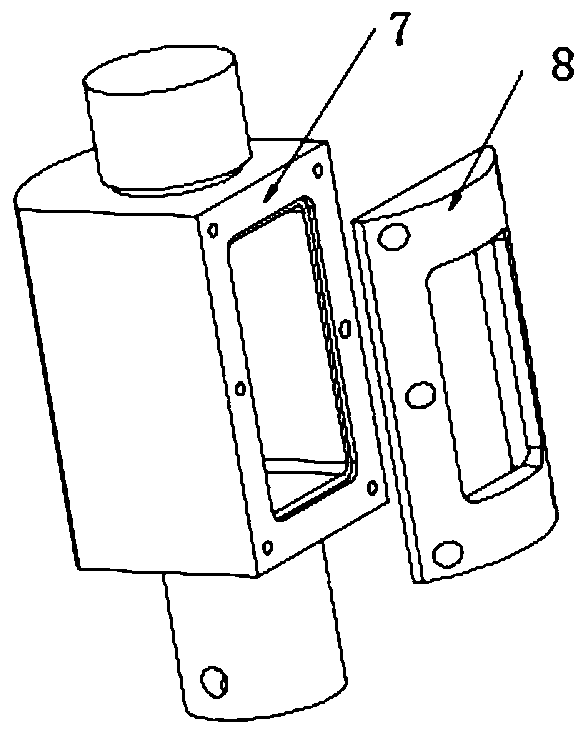

[0036]When the staff operates the smart fastener on site, the tension value of the tension sensor changes to generate a tension signal. After the signal is amplified by the amplifier circuit, AD conversion is performed. The CPU detects the current tension value through the signal value after AD conversion, and Determine whether the current tension value exceeds the specified tension range, send the tension value to the background server through the wireless module, and notify the background staff whether the fastener is in an anti-slip state, and the background staff determine the current fastener position according to the fastener label At the same time, the CPU controls the indicator lights seen on both sides of the communication metal shell body to display the corresponding state: the red light flashes at 1Hz; the threshold range is reached during installation: the green light flashes at 1Hz and goes out after 20s; when it is in the anti-slip state, the red light and the gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com