Tobacco shred perfuming uniformity evaluation method based on PCA ellipse area

An evaluation method and uniformity technology, which is applied in the field of evaluation of flavoring uniformity of shredded tobacco based on PCA ellipse area, can solve the problems of complex chemical composition, low flavor content, difficult to add markers, etc., and achieve simplified process and accurate results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The evaluation method for flavoring uniformity of shredded tobacco based on PCA ellipse area of the present embodiment comprises the following steps:

[0042] Step (1), prepare control samples

[0043] Take A brand shredded tobacco, and use A brand essence to flavor evenly at 3.3‰ (mass ratio). The flavored shredded tobacco was divided into 16 parts on average, and 10 g of each part was sampled, and each part was packed in a ziplock bag for testing to obtain a control sample.

[0044] Step (2), prepare the sample to be tested

[0045] Divide the finished shredded tobacco sample of brand A into 16 parts on average, take 10 g of each part, and put them in ziplock bags for testing, so as to obtain the samples to be tested.

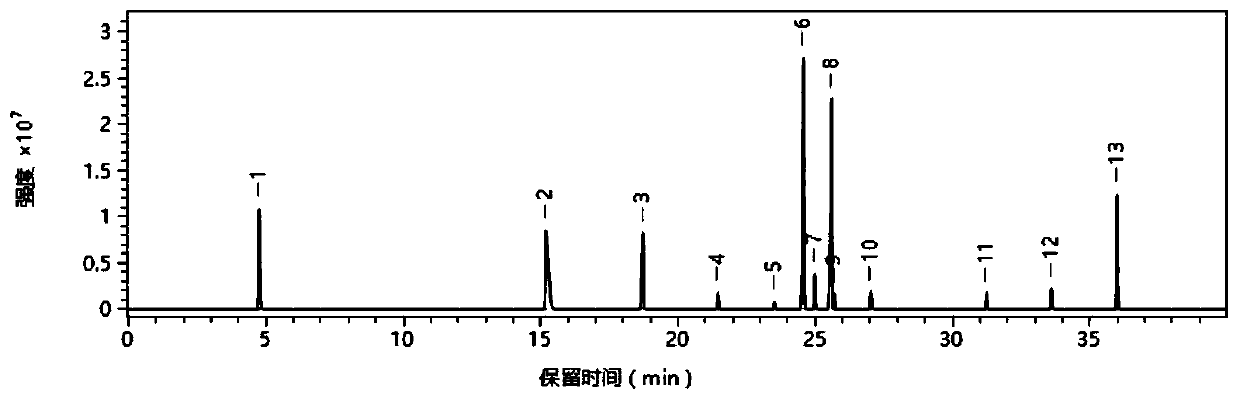

[0046] Step (3), solid phase microextraction-gas chromatography-mass spectrometry analysis

[0047] Solid-phase microextraction-gas chromatography-mass spectrometry was performed on the control sample and the sample to be tested. Accurately weighe...

Embodiment 2

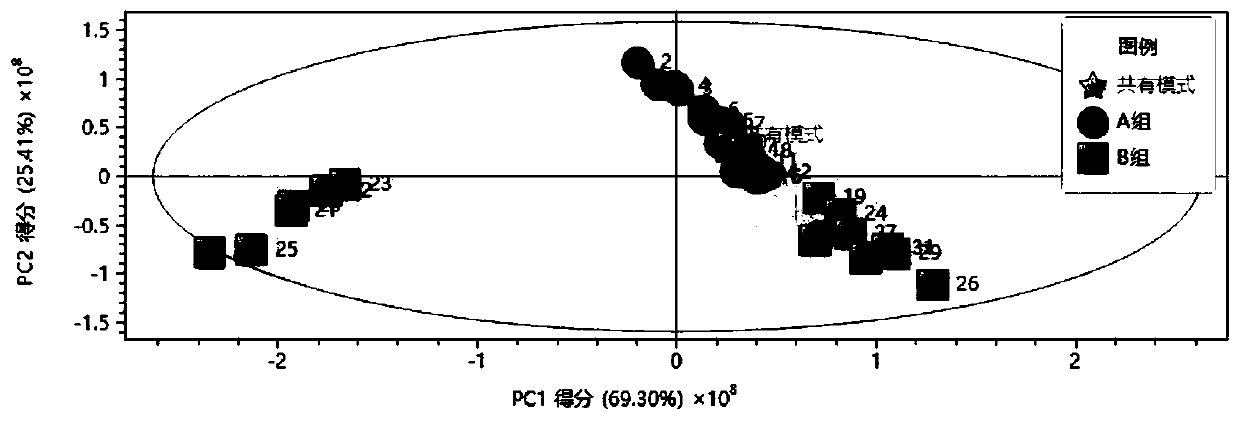

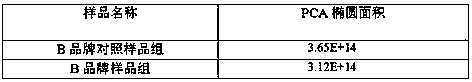

[0072] The evaluation method for flavoring uniformity of shredded tobacco based on PCA ellipse area of the present embodiment comprises the following steps:

[0073] Step (1), prepare control samples

[0074] Take B brand shredded tobacco, and use B brand essence to evenly flavor at 3.5‰ (mass ratio). The flavored shredded tobacco was divided into 10 parts on average, and 10 g of samples were taken from each part, which were respectively packed in ziplock bags to be tested, so as to obtain control samples.

[0075] Step (2), prepare the sample to be tested

[0076] Divide the finished shredded tobacco sample of brand B into 10 parts on average, take 10 g of each part, and put them in ziplock bags for testing to obtain the samples to be tested.

[0077] Step (3), solid phase microextraction-gas chromatography-mass spectrometry analysis

[0078] Perform solid-phase microextraction-gas chromatography-mass spectrometry analysis on the above-mentioned control sample and the sa...

Embodiment 3

[0088] The evaluation method for flavoring uniformity of shredded tobacco based on PCA ellipse area of the present embodiment comprises the following steps:

[0089] Step (1), prepare control samples

[0090] Take C brand shredded tobacco, and use C brand essence to flavor evenly at 3.1‰ (mass ratio). The flavored shredded tobacco was divided into 25 parts on average, and 10 g of each part was sampled, respectively packed in ziplock bags for testing to obtain a control sample.

[0091] Step (2), prepare the sample to be tested

[0092] Divide the finished shredded tobacco sample of brand D into 25 parts on average, take 10g of each part, put them in ziplock bags for testing, and obtain the samples to be tested.

[0093] Step (3), solid phase microextraction-gas chromatography-mass spectrometry analysis

[0094] Perform solid-phase microextraction-gas chromatography-mass spectrometry analysis on the above-mentioned control sample and the sample to be tested, specifically t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com