Tyre unloader

A kind of unloader, tire technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problem of unable to meet the needs of rapid development of rail transit, lack of professional machinery, etc., to improve the automatic production line of rail transit, fill technology and market blank effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

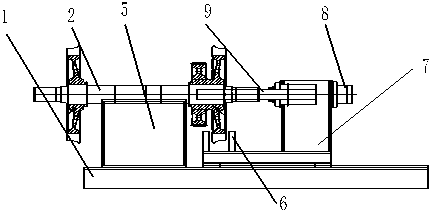

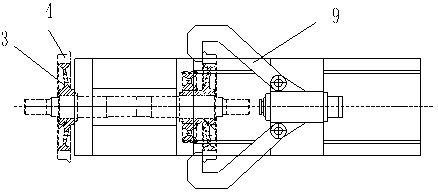

[0010] Such as Figure 1 to Figure 2 As shown, the present invention discloses a tire unloading machine, which has a base 1, an oil cylinder seat 7 is arranged on one end of the base 1, and an axial oil cylinder 8 is arranged on a fixed support. The oil cylinder is a compound oil cylinder, and movable pull hooks 9 are symmetrically arranged on both sides of the piston rod sleeve of the compound oil cylinder, and the hook heads are opposite to each other. The other end of the base is provided with a support shaft seat 5, and a support is provided on the base, corresponding to the wheels. Wheel bracket.

[0011] The composite oil cylinder has three layers, which are respectively a piston rod, a piston rod sleeve and a cylinder sleeve from the inside to the outside.

[0012] Working process of the present invention is as follows:

[0013] When unloading the tire, first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com