Wheel hub unloading and dismounting machine

A technology for unloading machines and tires, applied in hand-held tools, manufacturing tools, etc., can solve the problems of unable to meet the needs of rapid development of rail transit, no professional machinery, etc., to fill the gaps in technology and market, easy to maintain and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

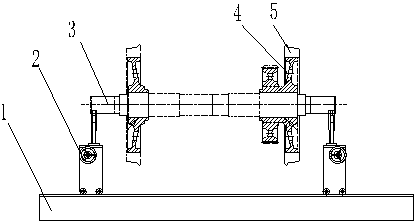

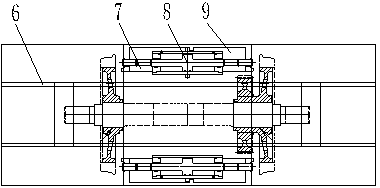

[0010] like Figure 1 to Figure 2 As shown, the present invention discloses a tire unloading machine, which has a base 1, and the middle axis of the base is symmetrically provided with an oil cylinder seat 9 and an axial oil cylinder 8, and movable supports 2 are provided at both ends of the base. The mobile bracket supports the journal of the axle to ensure the stability of the workpiece lifting. The mobile bracket walks on the guide rail of the base, and the walking is follow-up, which will not cause any resistance to the unloading process. Corresponding to the middle of the wheel pair, a stopper seat 7 is arranged, and the said stopper seat is movable to adapt to the withdrawing work of split wheelsets of different diameters. The axial oil cylinder is flush with the height of the axle, and the piston rod of the oil cylinder is facing the wheel rim.

[0011] Worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com