Train wheel oiling machine

An oiler and wheel technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of unsatisfactory users, low work efficiency, high labor intensity, etc., and achieve perfect rail transit automation production line and structure. Simple, Efficient Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

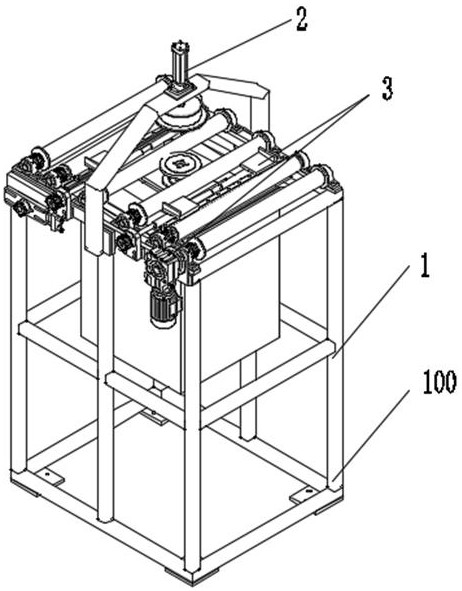

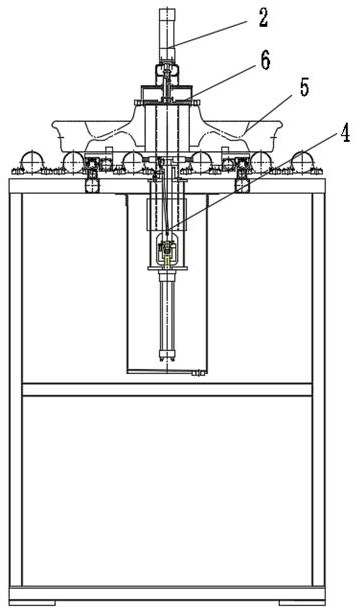

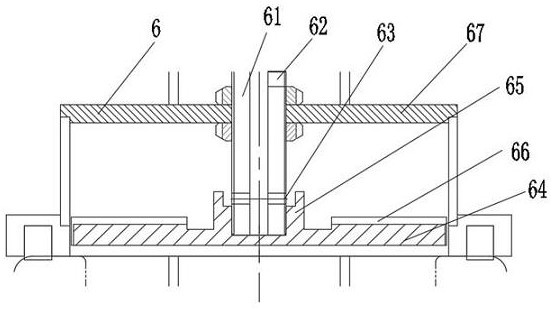

[0027] like Figure 1 to Figure 4 As shown in the figure, the present invention discloses a train wheel oiler, which includes a bracket 1, a lower pressure oil cylinder 2, a wheel conveying and clamping fixing assembly 3, and an oil brushing device 4. The piston rod of the lower pressure oil cylinder is set under the There is an oil separator 6, a nozzle 61 and an interface 62 are arranged in the middle of the oil separator, a nozzle 63 is arranged at the lower part of the nozzle, and the lower end of the nozzle is inserted into the raised ring 65 in the middle of the oil separator 64, and the nozzle is lower than In the annular mouth, the oil distribution grooves 66 are evenly distributed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com