Traction motor node press-mounting and withdrawing machine

A technology of traction motor and unloading machine, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient strength of the workbench, damage to the traction motor aperture lifting lug, time-consuming and labor-intensive problems, and achieve a perfect rail transit automation production line , fill the gaps in technology and market, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

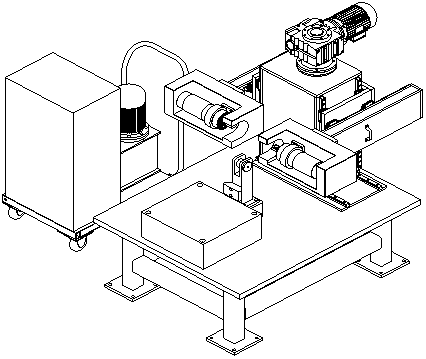

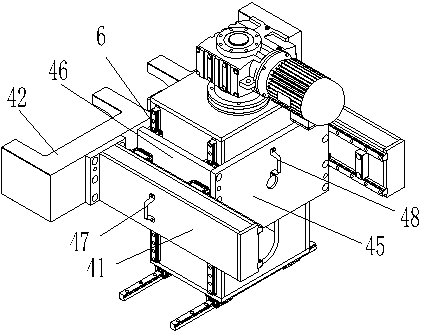

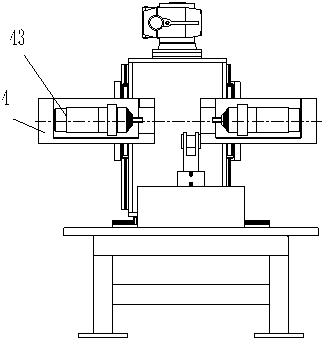

[0024] Such as Figure 1 to Figure 13 As shown, the present invention discloses a traction motor node press assembly and unloading machine, including electric control and hydraulic system, it has a workbench 1, a box-shaped support 2 is arranged on the workbench, and a lifting device is arranged on the box-shaped support 3 and telescopic device 4, described telescopic device is to be provided with recessed fork 42 before flat plate 41, and has two symmetrically located at box-shaped bracket left and right both sides, left and right flat plate inner side is connected with transition plate 46, left , the right transition plate back is provided with connecting plate 45, and connecting plate is connected with nut connecting block 35, and nut connecting block cooperates with the screw mandrel 34 of lifting device, is provided with guide rail and guide groove A5 to cooperate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com