Lofting blanket

A lofting blanket and flexible technology, applied in the field of lofting blankets, can solve the problems of deviation in pipeline installation, poor pipeline connection, and inability to install, and achieve the effects of less space occupation, low cost, and avoiding connection deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

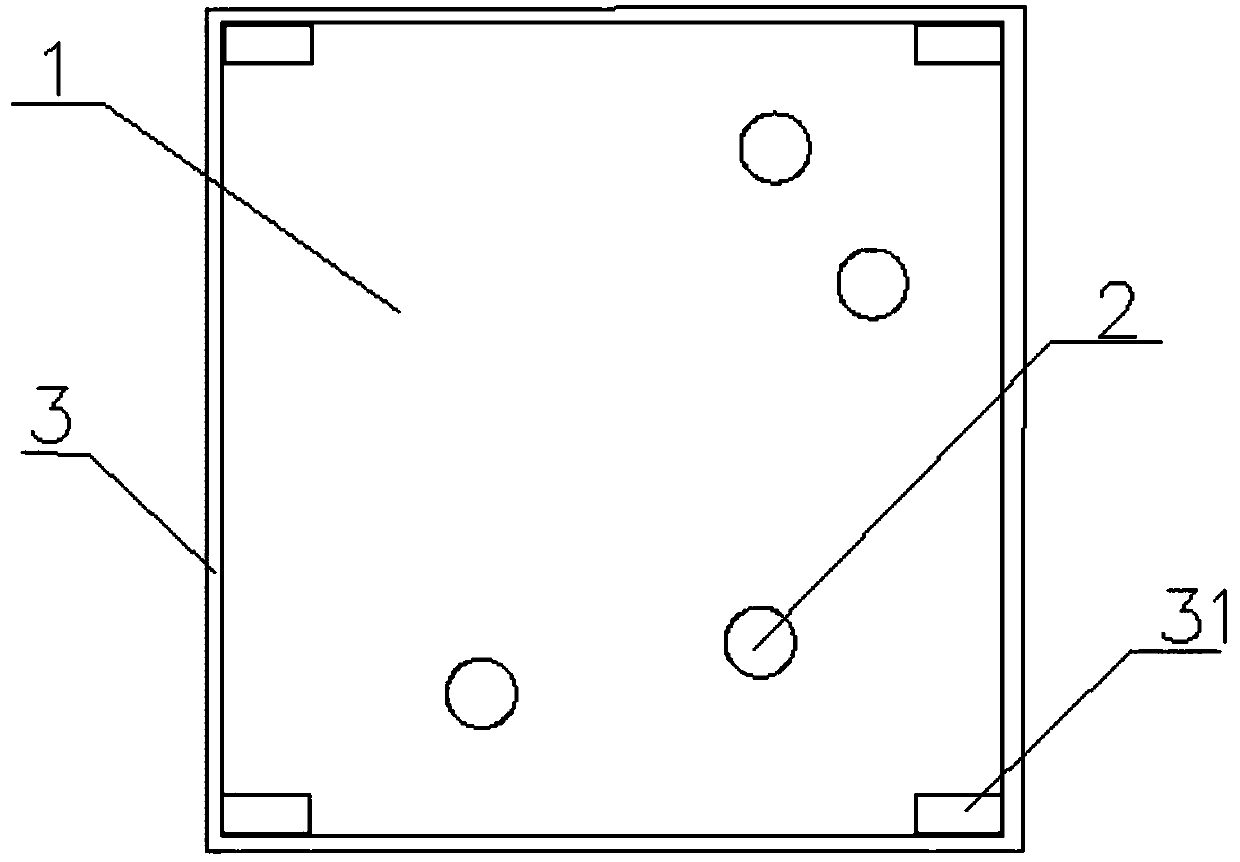

[0012] Such as figure 1 The lofting blanket shown includes a flexible plane 1 made of polyvinyl chloride resin material, and, arranged on the flexible plane, a plurality of positioning holes 2 adapted to a plurality of water-stop joints; wherein, the lofting The edge of the blanket is also provided with a positioning edge 3 for positioning it on the template, and a positioning clip 31 is provided on the positioning edge 3 .

Embodiment 2

[0014] The use of staked blankets

[0015] When laying the first layer of toilet pipes, firstly cut the staked blanket according to the size of the toilet so that the edge of the toilet overlaps with the staked blanket, and selectively paste the sticky positioning edge on the edge of the staked blanket; then according to the instructions of the engineering drawing Use a ruler to measure the position of the reserved hole and mark it, then use tools to leave the reserved hole position blank to form a positioning hole, and finally spray paint at the positioning hole. The pipeline positioning on the first floor is completed; when the pipeline is positioned on the second floor, align the edge of the lofted blanket with the toilet plane, and spray paint on the positioning hole formed when the pipeline is laid on the first floor; similarly, in the same building When laying and positioning the bathroom pipes, just place the staked blanket directly on the bathroom plane for positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com