A downhole control pipeline plugging process and system

A technology for controlling systems and pipelines, applied in wellbore/well components, surveying, earth-moving drilling, etc., can solve the problems of high cost, complicated maintenance or replacement operations, time-consuming and labor-intensive, etc., and achieve low cost, easy operation, and avoid sealing. The effect of blocking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

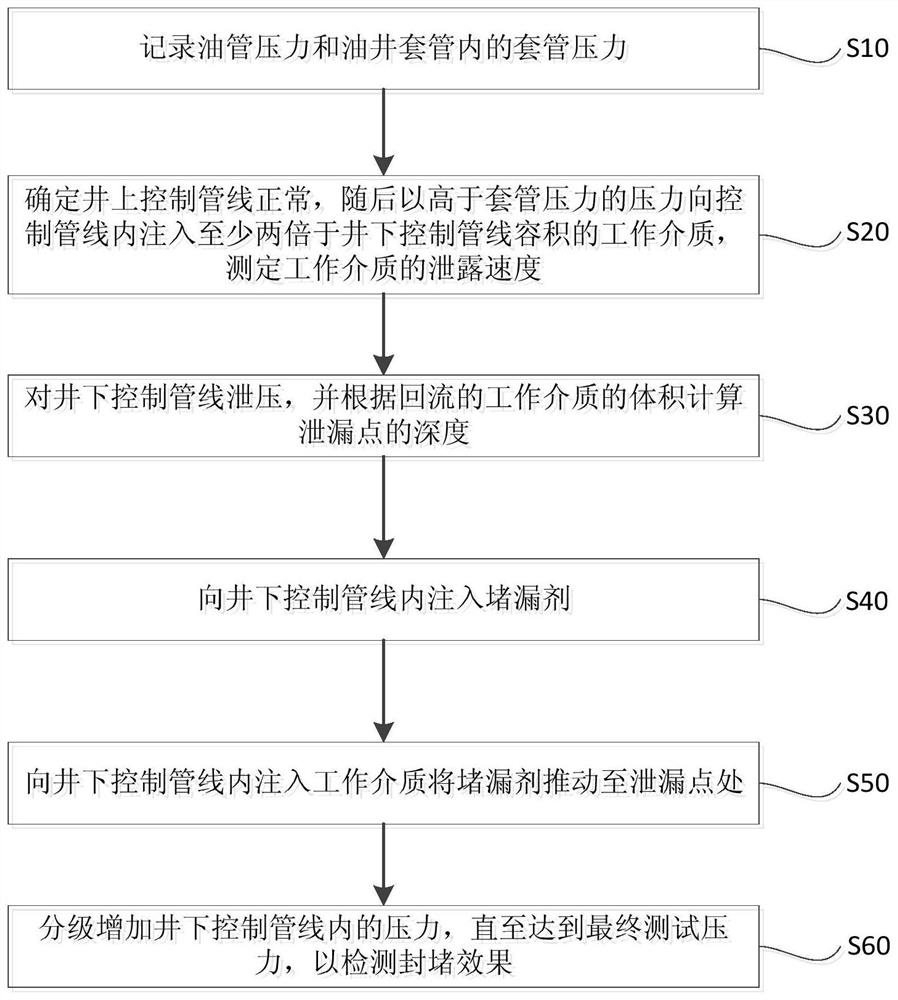

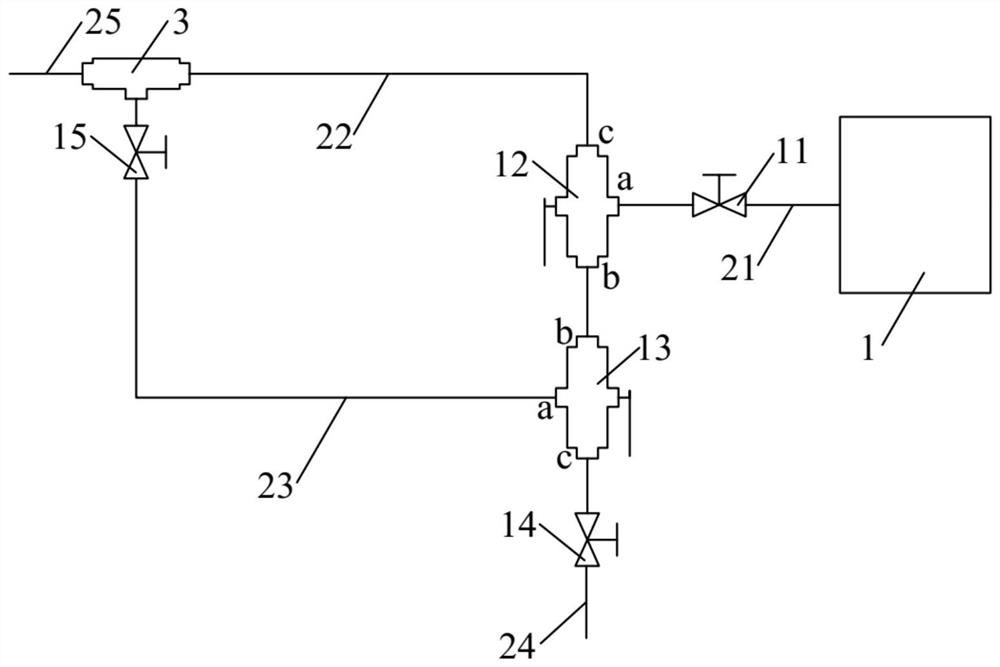

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0033] This embodiment provides a plugging process for downhole control pipelines, which is mainly aimed at downhole control pipelines (hydraulic control pipelines) of hydraulically controlled tools (downhole safety valves, etc.) in oil and gas wells. The agent can be used to seal the leakage point of the downhole control pipeline, and of course it can also be used to seal the leakage point of other hydraulic control pipelines. Among them, the plugging agent is liquid, and there is a pressure difference at the leak point. Under the action of the pressure difference, the liquid molecules of the plugging agent coalesce to form a solid plug with a certain degree of flexibility, which gradually accumulates from the edge of the leak point to the center. Final plugging of leaks

[0034] like figure 1 Sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com