Top water exclusion effect identification method

A technology for oil production wells and packers, which is applied in the field of water isolation and oil production effect identification, and can solve the problems of complex process, high cost, inability to judge and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

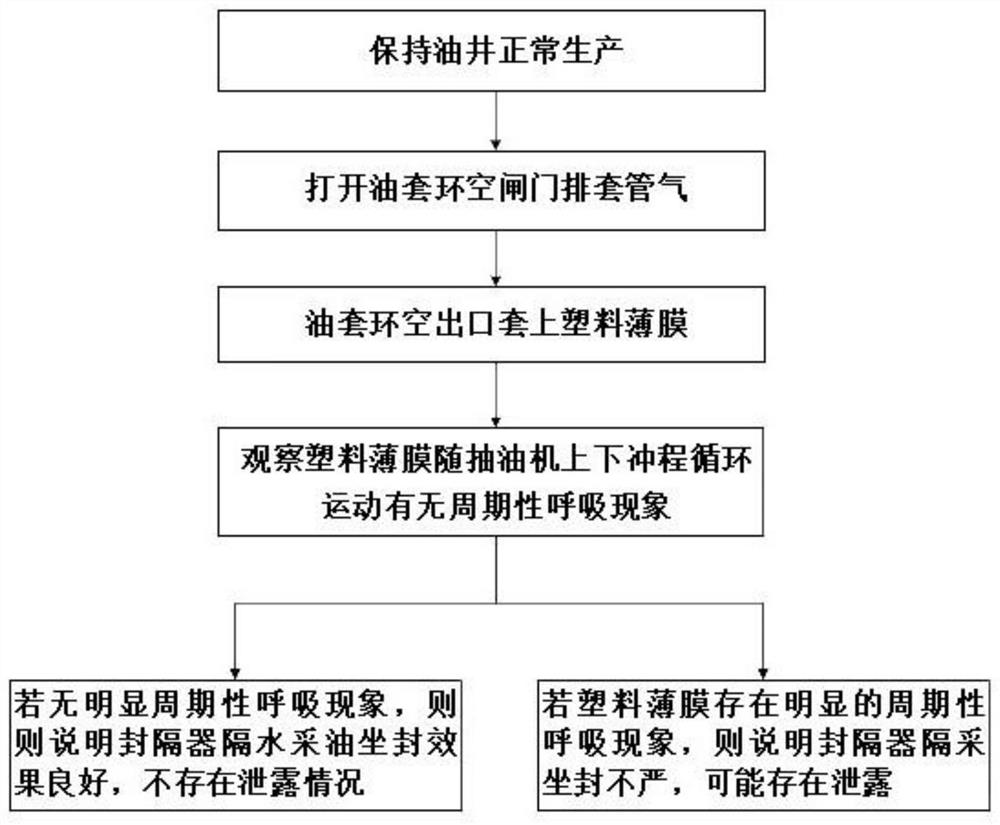

[0038]This embodiment provides a method for ground recognition of the effect of water-proof oil production, such asfigure 1 As shown, including the following steps:

[0039]S1. Maintain normal production of isolation oil wells;

[0040]S2. Open the oil sleeve annulus gate and vent the casing gas;

[0041]S3. Install a water-proof oil extraction effect identification device at the outlet of the oil jacket annulus;

[0042]S4. Judge the setting effect of the packer through the water-insulating oil recovery effect identification device; if the packer is set well, it can indicate that the water-insulating oil recovery measures are effective, even if the oil well productivity cannot be recovered in the later stage, it can be ruled out The problem of the failure of the packer's isolation and production is to eliminate interference factors for further searching for the decline of oil well productivity.

Embodiment 2

[0044]On the basis of Example 1, since the plastic film has good sealing performance and is relatively soft, it responds significantly to the breathing phenomenon existing in the annulus of the oil sleeve, so the present invention selects the plastic film as the test material.

[0045]In the present invention, a plastic film is sheathed on the annulus outlet of the oil sleeve, and the pumping unit drives the piston of the pumping pump to reciprocate up and down during normal oil well production, causing the oil sleeve annulus to fluctuate up and down, and breathing phenomenon occurs at the annulus outlet of the oil sleeve. According to the principle, if the plastic film has no obvious periodic respiration, it means that the packer has a good setting effect for water and oil extraction and there is no leakage. If the plastic film has obvious periodic respiration, it means that the packer is not tightly isolated and set, and there is leakage.

[0046]Specifically, the ground recognition met...

Embodiment 3

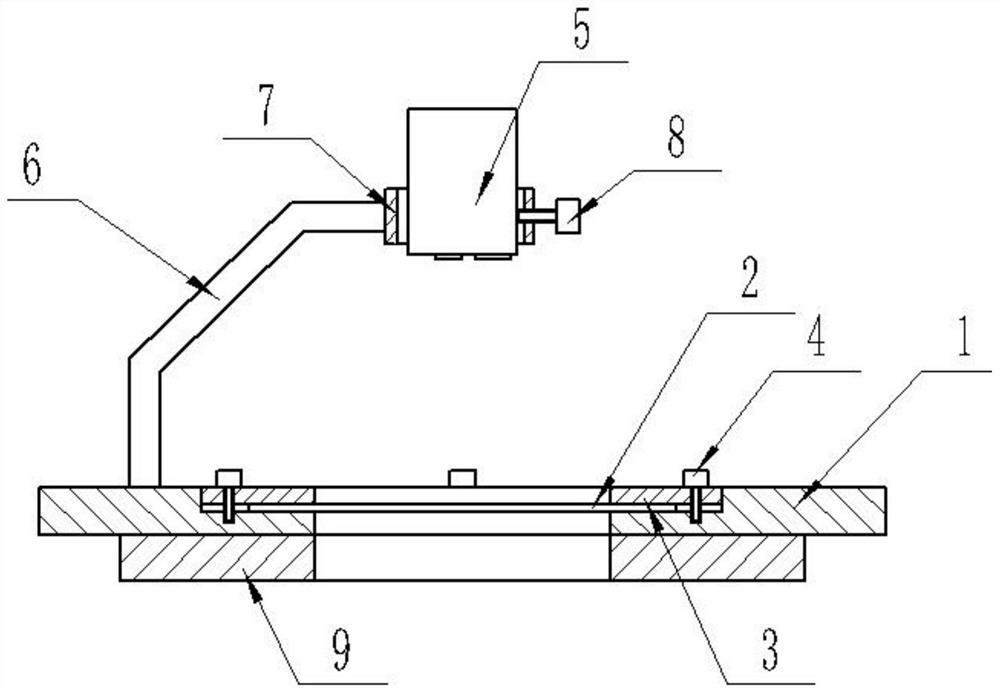

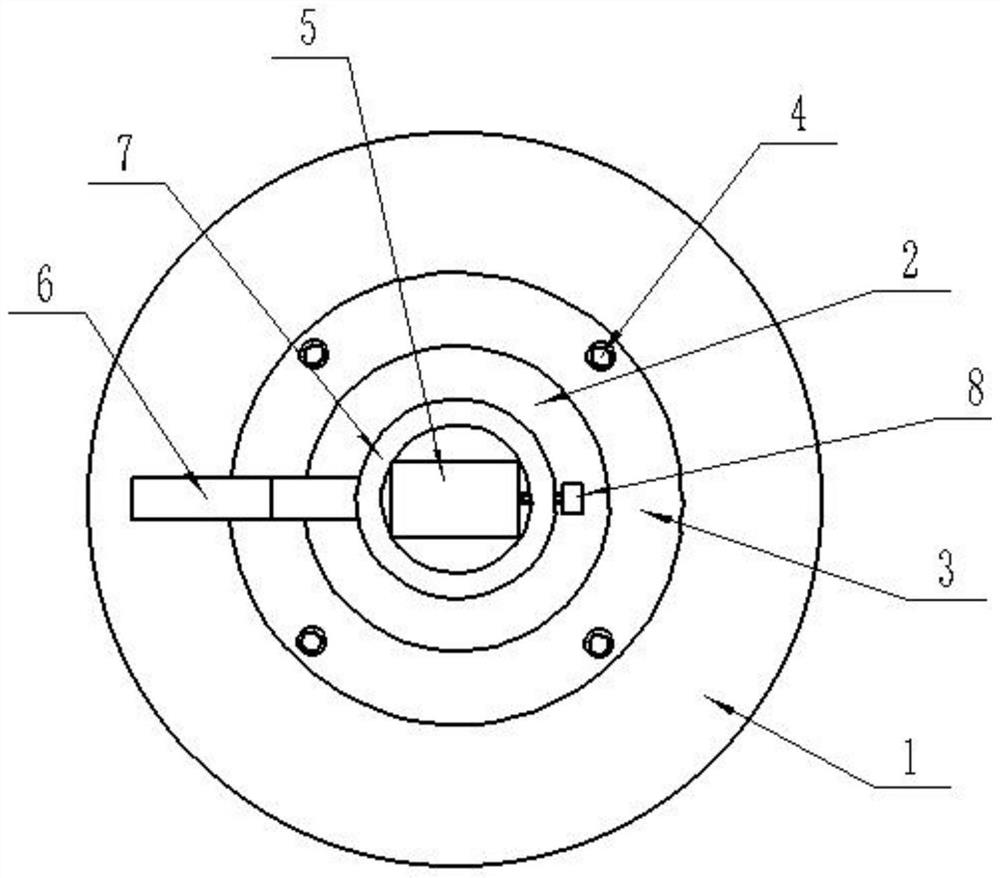

[0057]In order to further optimize the ground identification method for water-insulating oil recovery effect, the present invention also provides a water-insulating oil recovery effect identification device, such asfigure 2 Shown, including:

[0058]The pressure plate 1 has a through hole in the axial direction;

[0059]Membrane 2, the membrane 2 can be detachably connected in the through hole;

[0060]Measuring part, the measuring part is detachably connected to the upper surface of the pressure plate 1, and the measuring end of the measuring part is perpendicular to the center of the upper surface of the film 2;

[0061]The sealing part is fixed at the bottom end of the pressure plate 1.

[0062]As a further optimization, the measuring part includes: a distance meter 5, a bracket 6, a clamping ring 7 and a positioning nut 8. One end of the bracket 6 is fixed on one side of the upper surface of the pressure plate 1, and the clamping ring 7 is fixed On the other side of the bracket 6, the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com