Fish controller with touch control locking mechanism

A touch and trigger technology, applied in fishing, fishing accessories, applications, etc., can solve the problems of operation fatigue, the fish controller is not suitable for long-distance fish retrieval, and inconvenient to use, and achieves the effect of reducing operation fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

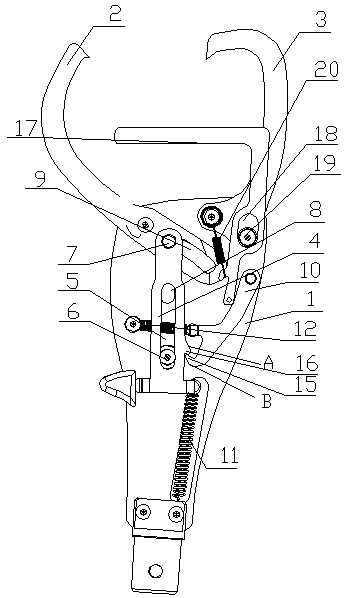

[0026] Such as figure 1 As shown, the fish control device with a touch control locking mechanism includes a base 1, the base 1 is a double-layer splint arranged at intervals and connected to each other, and the front end of the base 1 is provided with a left jaw 2 and a The right jaw 3, wherein the left jaw 2 is a movable chuck, the right jaw 3 is a fixed chuck, the base 1 is also connected with a trigger 4 for driving the left jaw 2 to open, the tail end of the trigger 4 is connected to the base A first elastic member 11 is connected between the tail ends of 1, and the first elastic member 11 is a tension spring.

[0027] The middle part of the trigger 4 is provided with a first chute 5 extending forward, the base 1 is provided with a first guide pin 6 cooperating with the first chute 5, the front end of the trigger 4 is connected with a second pin 7, the base 1 is provided with a second chute 8 extending forward, and the left jaw 2 is provided with an arc-shaped groove 9, a...

no. 2 example

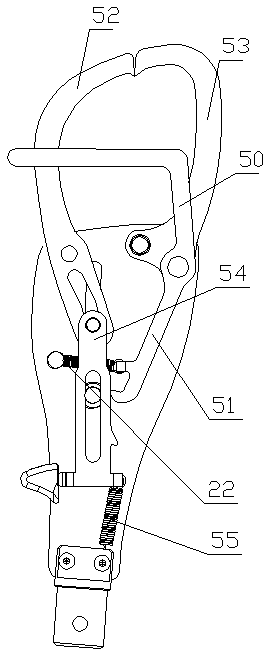

[0034] As shown in the figure, the structure of the second embodiment is basically the same as that of the first embodiment, the difference is that the trigger piece 50 is L-shaped, and the vertical section is integrated with the front end of the locking piece 51, the trigger piece 50 The horizontal section is horizontally arranged on one side of the left jaw 52 and the right jaw 53, so that when the left jaw 52 or the right jaw 53 extends into the fish mouth, the horizontal section of the trigger 50 can be pushed to rotate, thereby driving the locking piece 51 counterclockwise Turning makes the trigger 54 reset under the action of the first elastic member 55, thereby driving the left jaw 2 and the right jaw 3 to close.

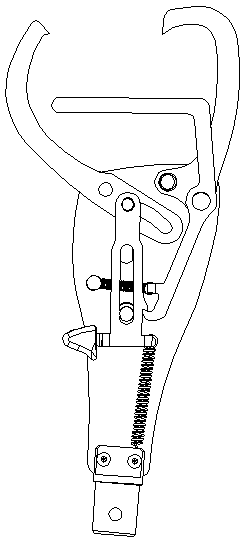

[0035] image 3 It is a structural diagram of the left jaw 52 and the right jaw 53 in the open state of the second embodiment, and the specific principle is the same as that of the first embodiment, which will not be repeated here.

no. 3 example

[0037] Such as Figure 4 As shown, the structure of the third embodiment is basically the same as that of the second embodiment, the difference is that the first elastic member 20 is a compression spring, one end of the compression spring 20 is connected to the first guide pin 21, and the other end is connected to the The rear end of the first sliding groove 23 of the trigger 22.

[0038] The second elastic member 26 adopts a compression spring, and the locking member 24 is provided with a guide rod 25 and a guide seat 27 cooperating with the guide rod 25. The guide rod 25 slides and is inserted in the guide seat 27, and the second elastic member 26 is inserted in the guide rod. 25 on.

[0039] The working principle of this embodiment is similar to that of the first embodiment, and will not be repeated here;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com