Gear shifting lamplight panel module

A panel mold and lighting technology, applied in passenger/cab lighting, signal devices, transportation and packaging, etc., can solve the problems of high cost, large number of parts, complex assembly structure, etc., achieve simple installation, uniform character brightness, reduce The effect of product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

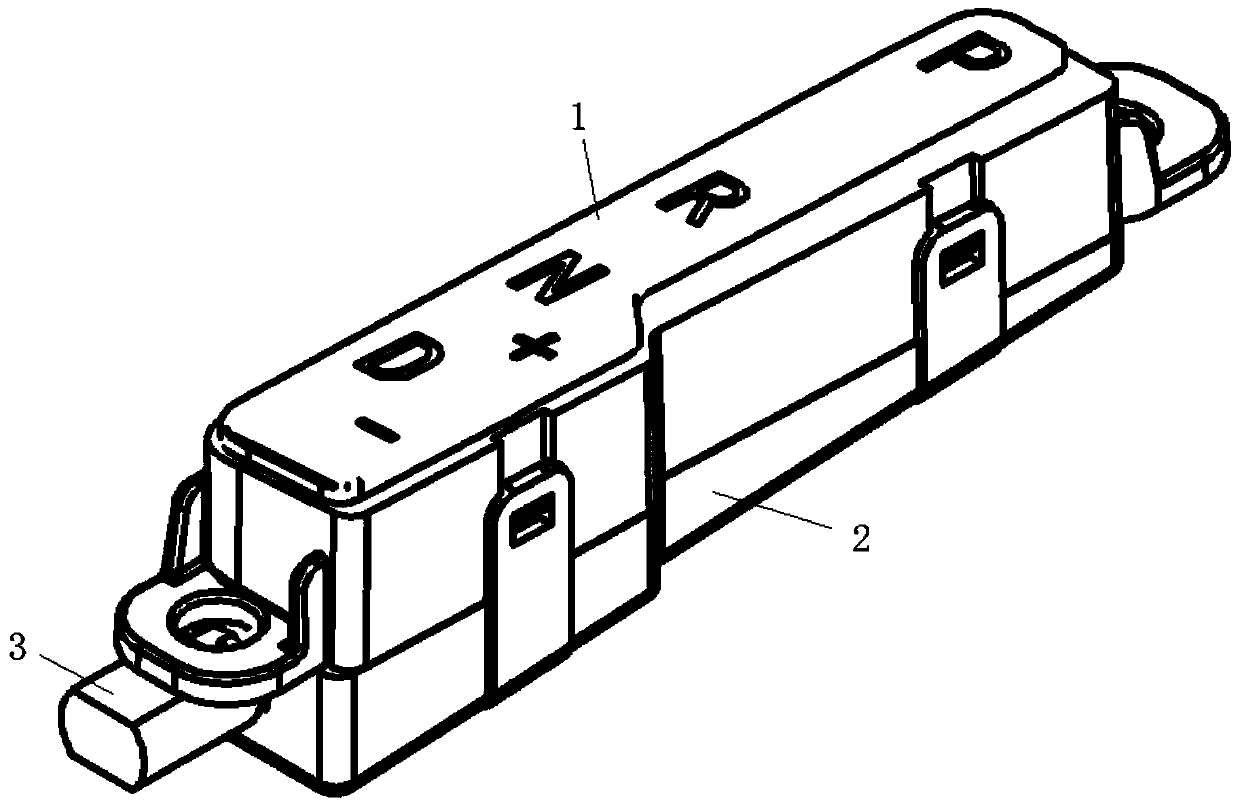

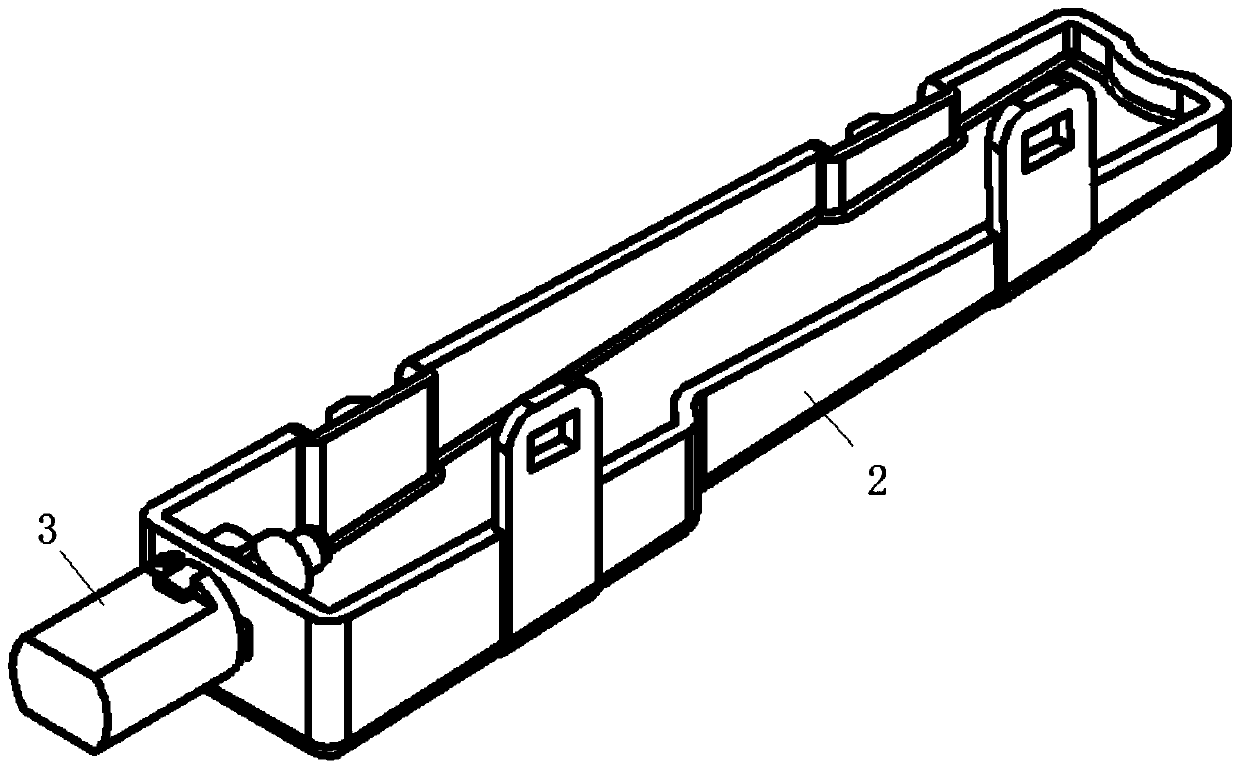

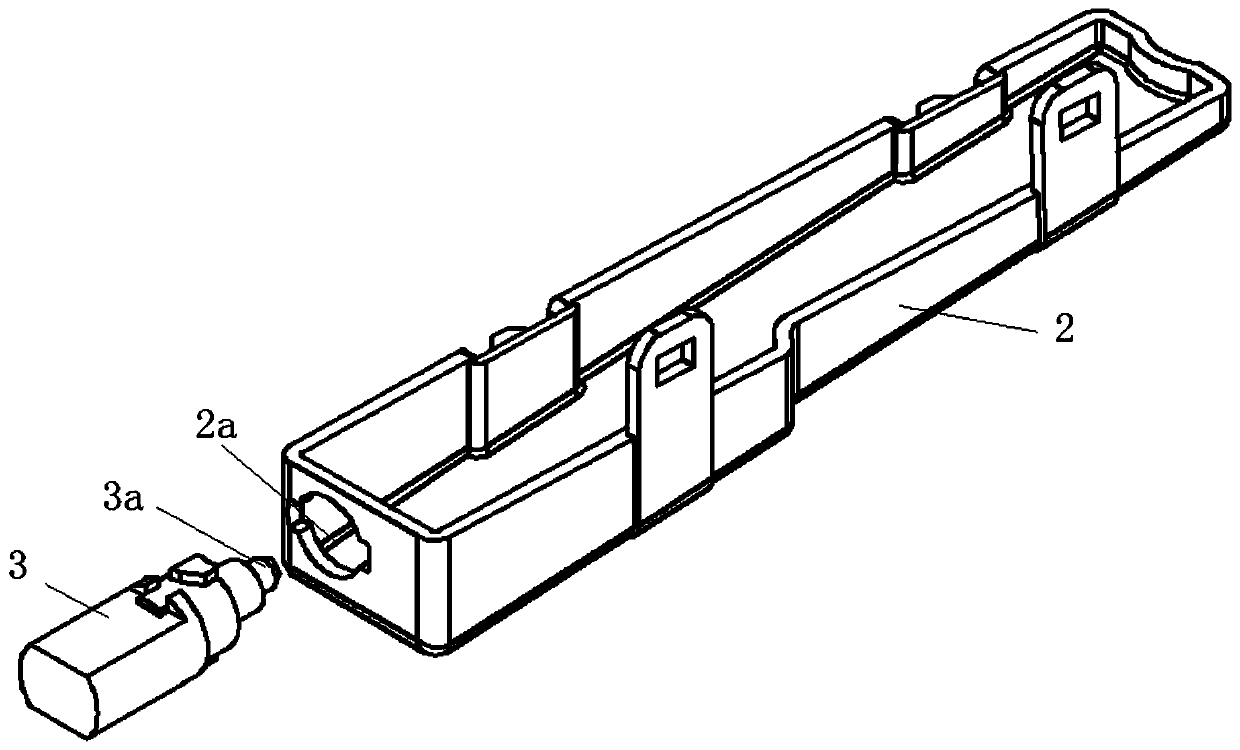

[0020] Such as Figure 1 to Figure 4 As shown, in this embodiment, a shift lighting panel module includes a background light mounting seat 2, a shift character panel 1 and a background light 3; the background light mounting seat 2 and the shift character panel 1 are box Shaped structure, and the shift character panel 1 is clamped with the backlight mounting seat 2 to form a closed cavity. A mounting hole 2a is opened on the side wall of the background light mounting seat 2, and the background light 3 is mounted on the background light mounting seat 2 in a clamping manner through the mounting hole 2a, and the light source part 3a of the background light 3 located within the cavity. The depth of the background light mounting seat 2 gradually decreases from the side where the background light 3 is located to the opposite side of the side where the background light 3 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com