Gob-side entry retaining support system coordinated deformation quantitative design method

A technology of deformation design and deformation amount, which is applied to mining equipment, earthwork drilling, filling, etc., and can solve problems such as threats to the safety of roadway retention, damage and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

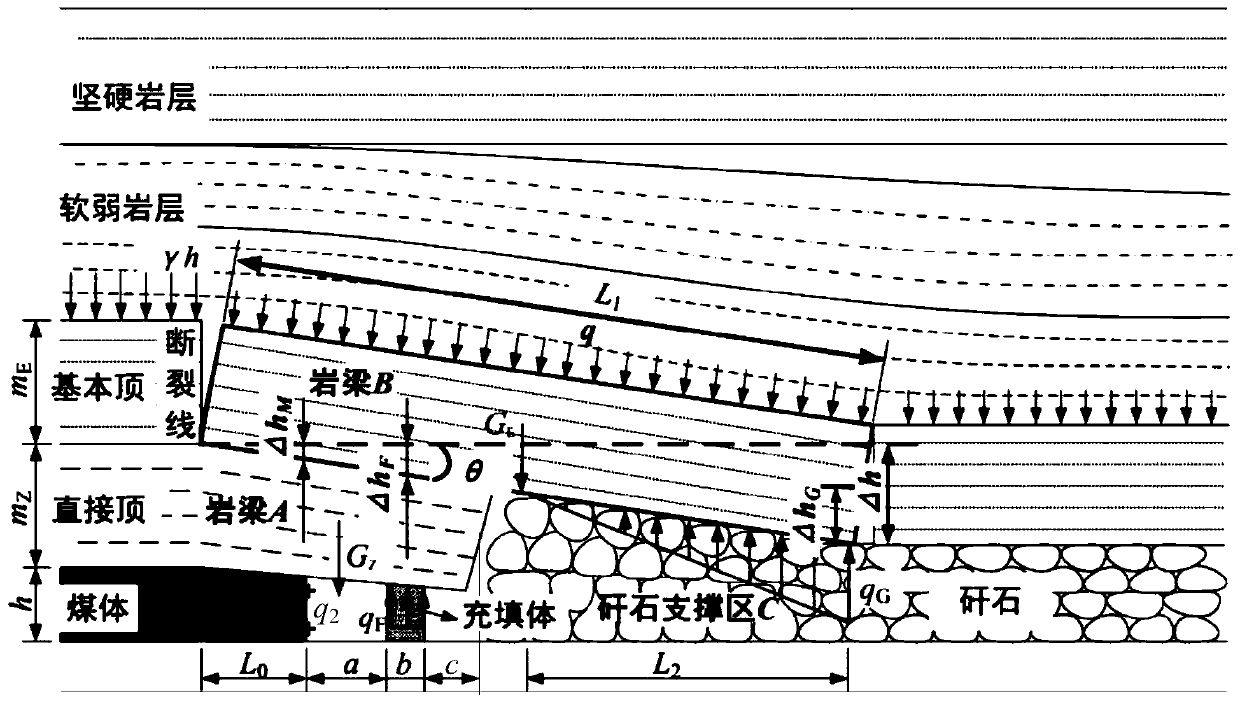

[0042] The present invention will be further described in conjunction with the accompanying drawings and examples. In the example, a certain mine is taken as an example. The average buried depth of the 3# coal seam at the -325m level of the coal mine is 325m, the average coal thickness is 3.5m, and the coal seam structure is relatively simple. Mining area 530 is the first mining area at the level of -325m, adopting fully mechanized coal mining method, and the full height is mined at one time. The immediate upper part of the coal seam is interbedded with fine sandstone and medium sandstone with a thickness of 8.2m, and the bulk density γ is 2500kg / m 3 . The basic roof is siltstone with a thickness of 12m, and the bulk density γ is 2500kg / m 3 . Further upwards are mudstones with a thickness of 4.5m (bulk density γ is 2300kg / m 3 ), rough sandstone with a thickness of 19.5m (bulk density γ is 2580kg / m 3 ), where mudstone is a weak rock formation and coarse sandstone is a hard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com