rubber seat

一种橡胶座、螺旋弹簧的技术,应用在车辆座椅、支承机器、运输和包装等方向,能够解决悬架构件损伤、橡胶座损伤、被嵌合凸部损伤等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

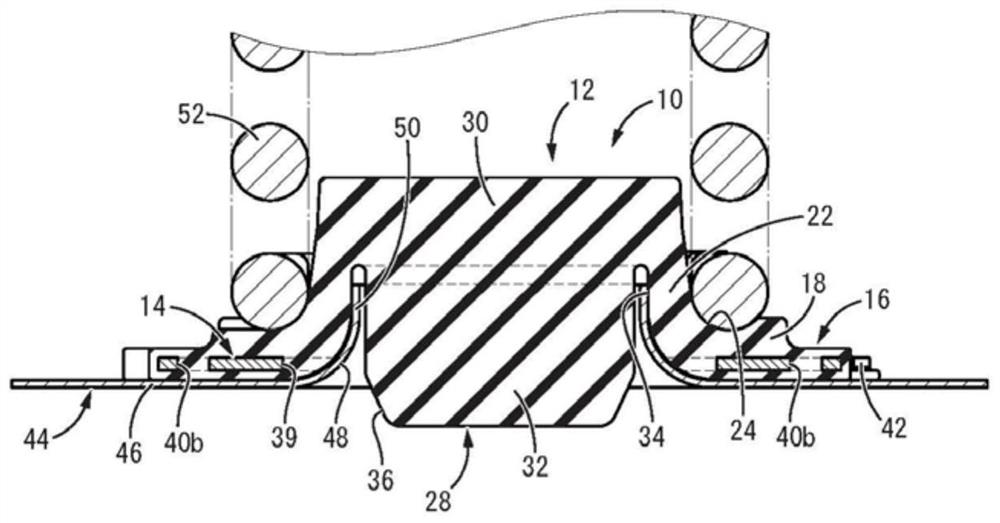

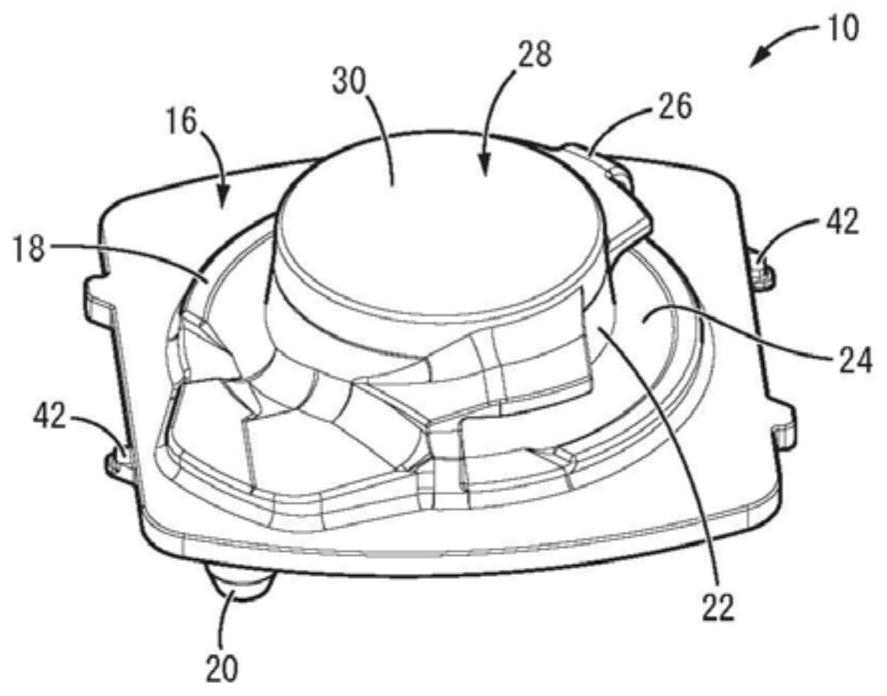

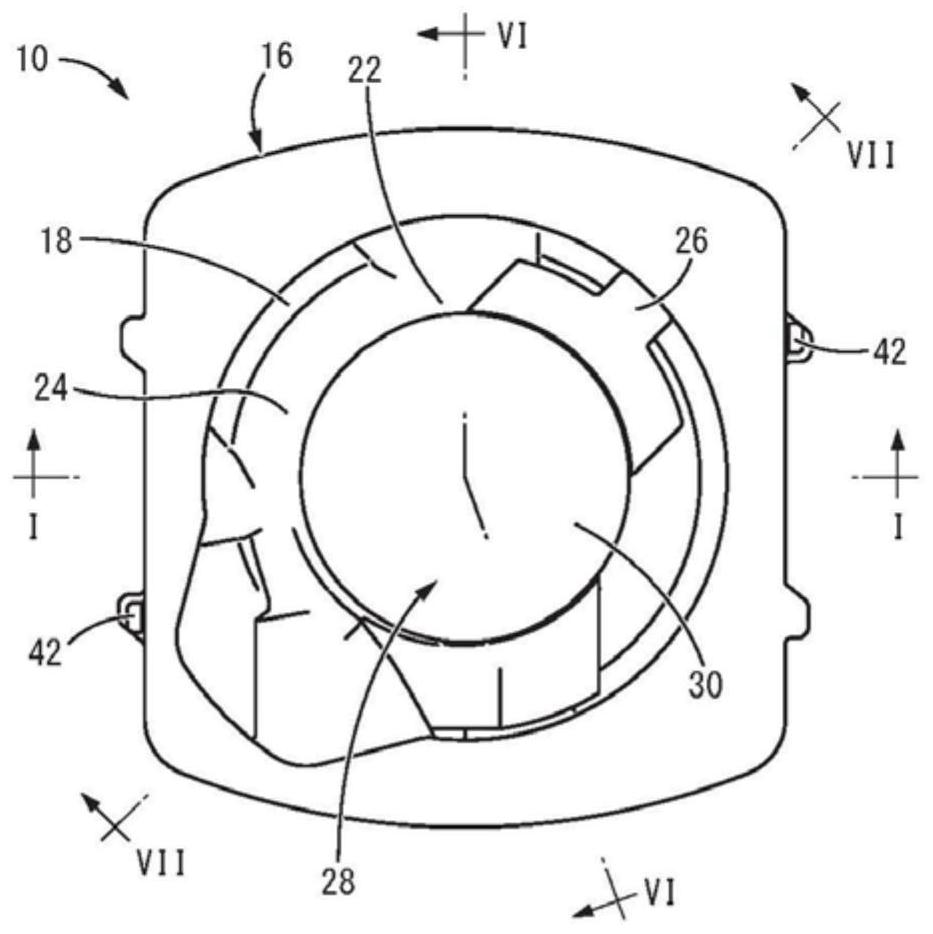

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0036] exist figure 1 In , the rubber seat 10 as the first embodiment of the present invention is shown in an assembled state with respect to vehicle assembly. Such as Figure 2 to Figure 7 As shown, the rubber seat 10 has a structure in which a reinforcing member 14 is fixedly connected to the rubber body 12 in an embedded state. In addition, in the following description, as a principle, the up-down direction refers to Figure 5 up and down direction, left and right direction refers to image 3 The left-right direction, the front-back direction refers to image 3 up and down direction.

[0037] More specifically, the rubber body 12 includes an outer peripheral plate-shaped portion 16 on the outer peripheral portion. The outer peripheral plate-like portion 16 has a ring plate shape with a substantially quadrangular outer periphery and a substantially circular inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com