Stone thrower toy

A technology of toys and stone carts, which is applied in the field of toys or props for scene simulation, can solve the problems of loose structure, inconvenience, and small elasticity, and achieve the effects of easy installation, increasing game fun, and exercising hands-on ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

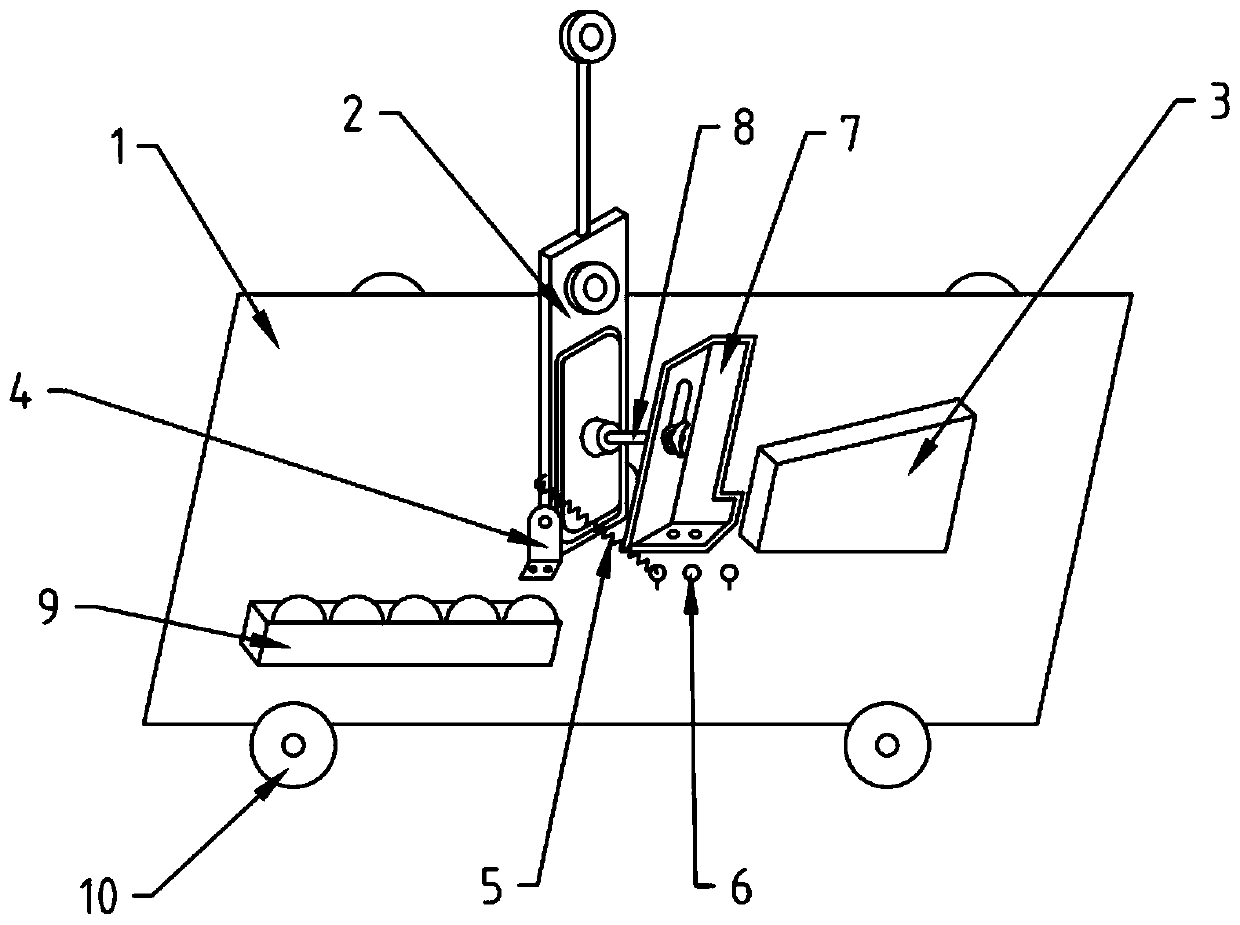

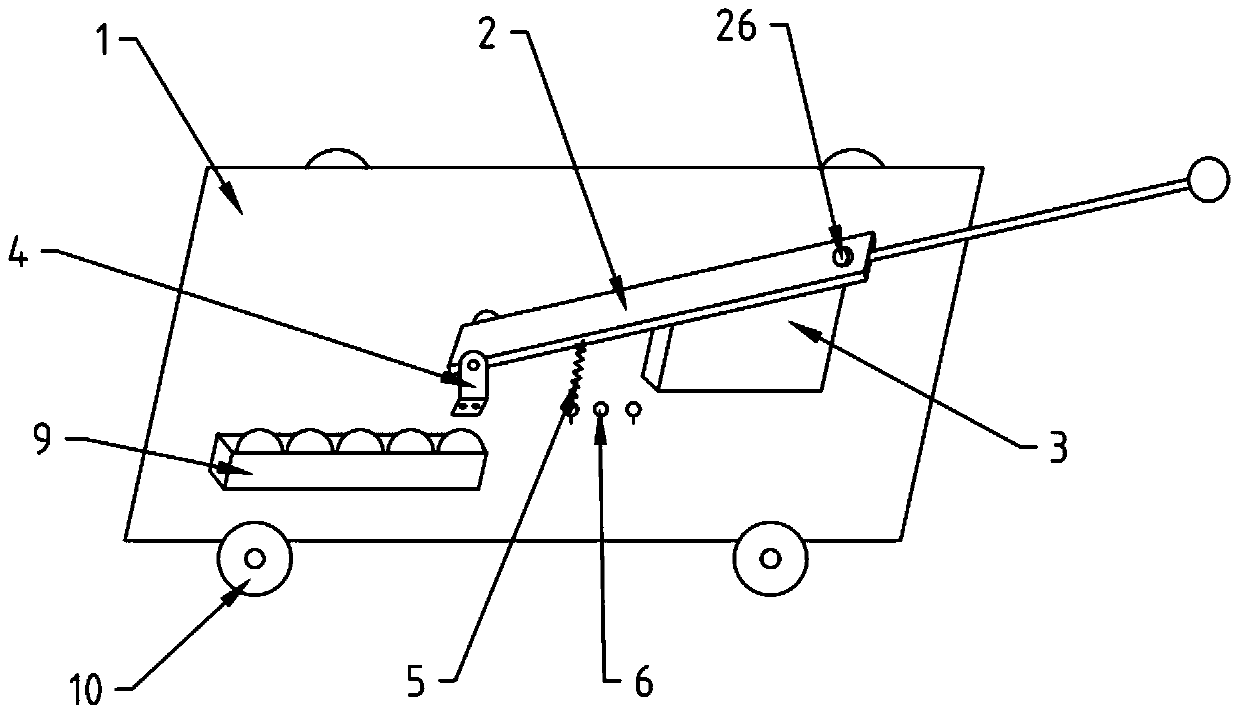

[0033] see figure 1 , figure 1 It is a kind of catapult toy of this embodiment, which comprises an underframe 1, a catapult arm 2, a front block 3 and a limit plate 7, and the catapult arm 2 is connected with a main catapult 23 and an auxiliary catapult 25, and the catapult arm 2 is connected with the fixed plate 4 on the bottom frame 1 through the rotating shaft, and can rotate freely around the rotating shaft. The side of the catapult arm 2 is connected with the pull ring 6 on the bottom frame 1 through the first spring 5. A detachable limit plate 7 is arranged between them, and a locking device 8 is installed on the limit plate 7, which can limit the stop position of the catapult arm 2 after it bounces up.

[0034] Combine below Figure 4 , in this embodiment, the sling arm 2 includes a sling 21, a rubber pad 22, a main sling 23, a telescopic rod 24 and an auxiliary sling 25, wherein the rubber pad 22 is located at the middle and lower part of the sling 21 for Buffer the...

Embodiment 2

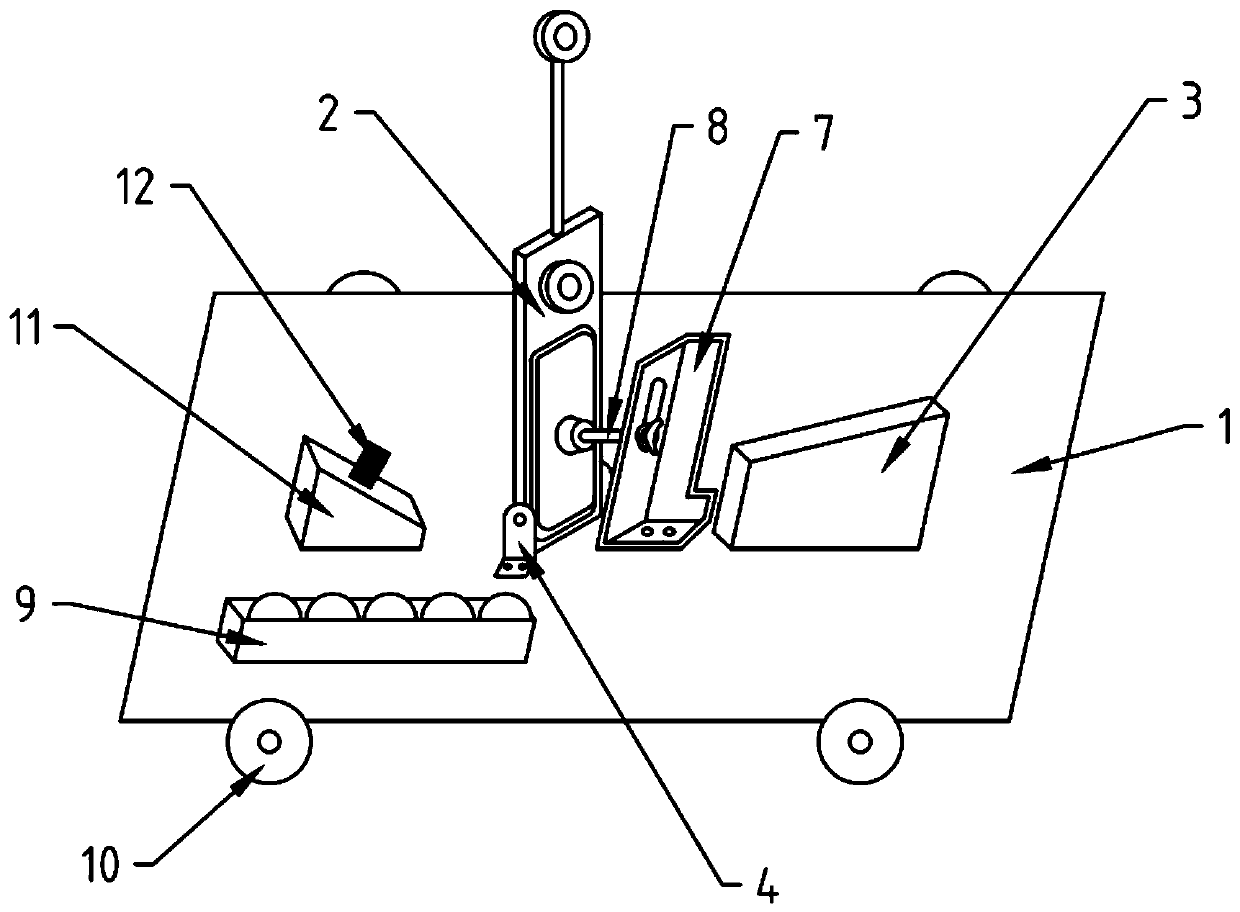

[0052] see image 3 , different from Embodiment 1, this embodiment is provided with an inclined rear stopper 11 at the rear end of the catapult arm 2, and a second spring 12 is provided at the middle position on it to provide elastic force for the catapult arm 2 to launch ammunition, and the installation on the The first spring 5 and the pull ring 6 on the side of the throwing arm 1.

[0053] Further, the upper end surface of the rear stopper 11 is an inclined plane, and the inclination angle is the same as the angle at which the catapult arm 2 rotates to the position of the rear stopper 11 .

[0054] This embodiment is mainly suitable for children with less strength. Because in Embodiment 1, the first spring 5 needs to be pulled back hard. For children with less strength, they cannot play without pulling the first spring 5. This embodiment During operation, it is only necessary to press down firmly after loading the ammunition on the catapult arm 2, which is more convenient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com