Ring grinder structure

A technology of ring rolling machine and driving mechanism, applied in metal rolling and other directions, can solve problems such as unfavorable implementation of movable seat movement, increase in weight and volume of movable seat, etc., and achieve outstanding substantive characteristics, good balance and good The effect of grinding ring work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

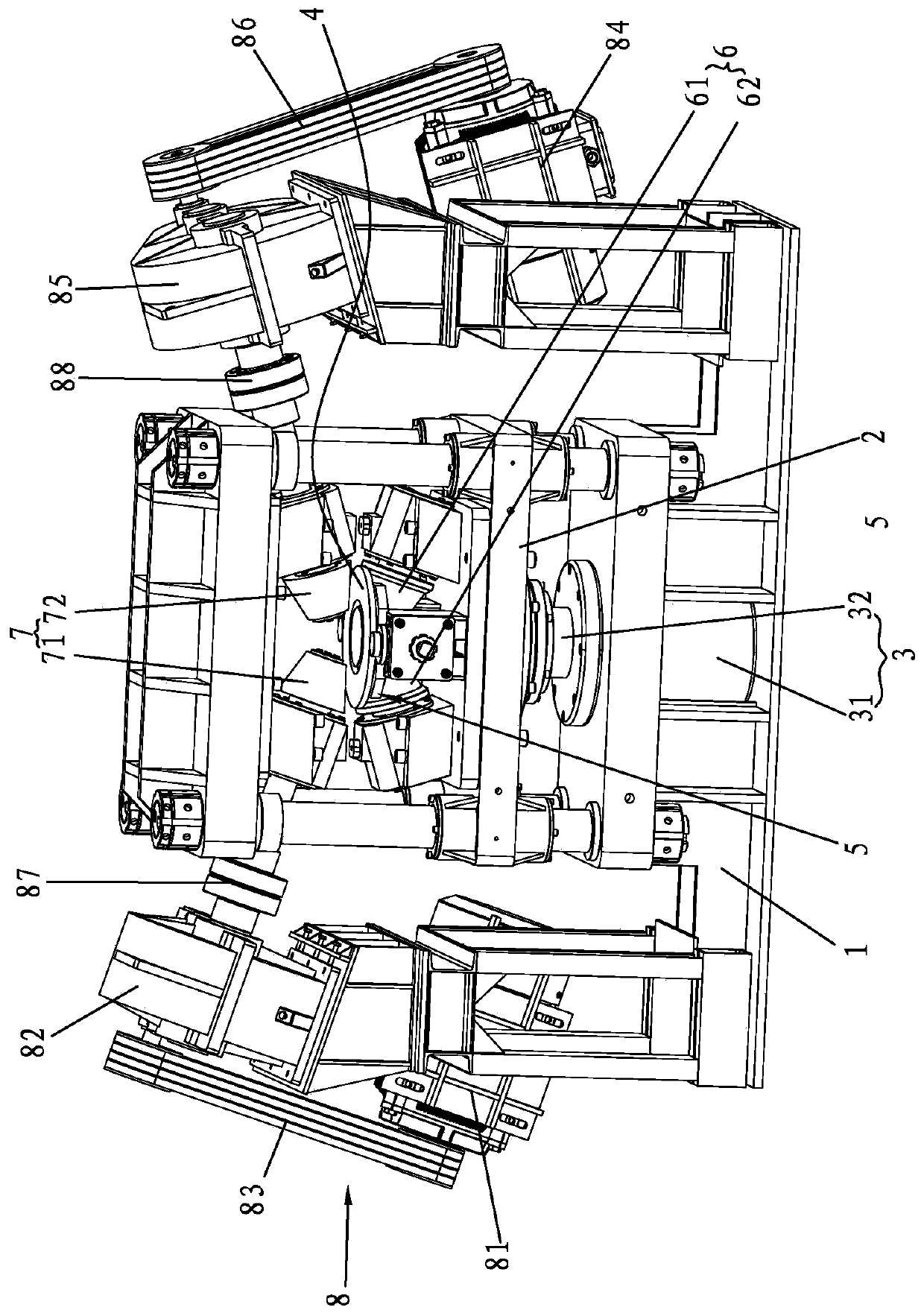

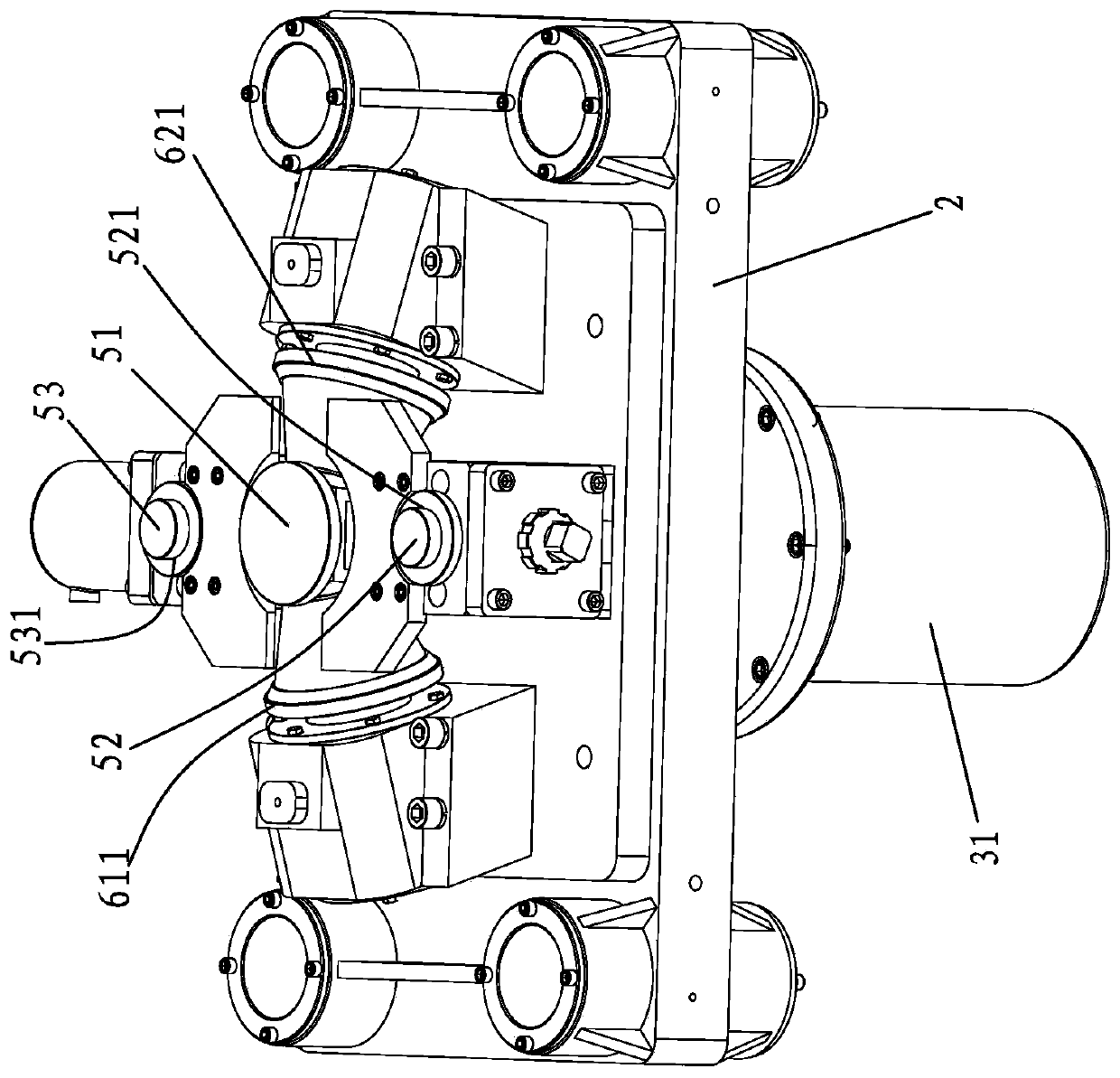

[0017] The features of the present invention and other relevant features are described in further detail below through the embodiments, so as to facilitate the understanding of those skilled in the art:

[0018] Such as Figure 1-Figure 2 As shown, a ring rolling machine structure includes a bracket 1, and the bracket 1 is provided with a vertical sliding seat 2 and a first driving mechanism for driving the vertical sliding seat 2 to slide up and down relative to the bracket 1 3. The vertical sliding seat 2 is provided with a limit support structure 5 for limit support of the annular end plate 4 and a driven tapered roller group 6 rotatably installed for rotational contact with the lower end surface of the annular end plate 4, The bracket 1 is also rotatably installed with a driving tapered roller group 7 located above the annular end plate 4 for rotating contact with the upper end surface of the annular end plate 4 and a second roller for driving the driving tapered roller gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com