Cleaning equipment for clothing auxiliary fabric

A technology for cleaning equipment and surface accessories, which is applied to the field of cleaning equipment for clothing and surface accessories, can solve the problem that the cleaning effect cannot meet the needs of use, and achieve the effects of low production cost, energy saving, and reasonable and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

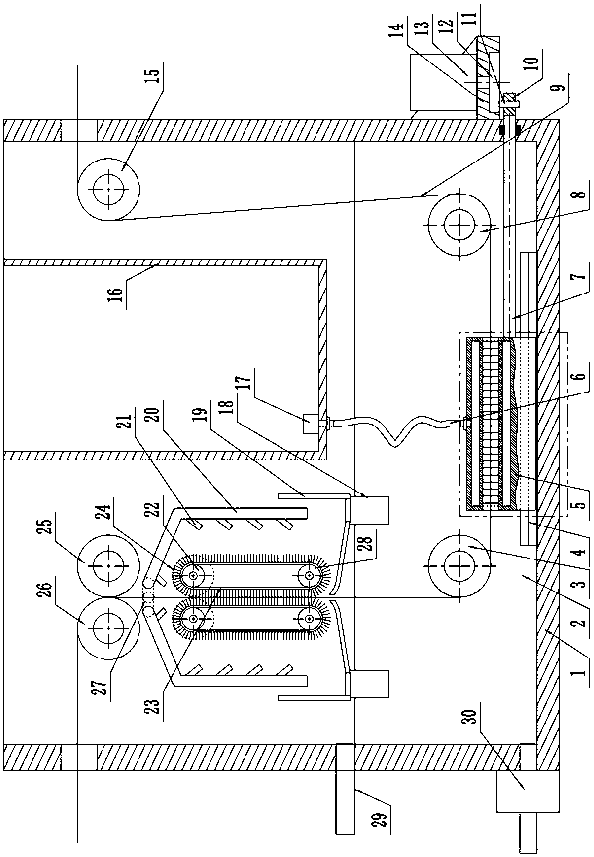

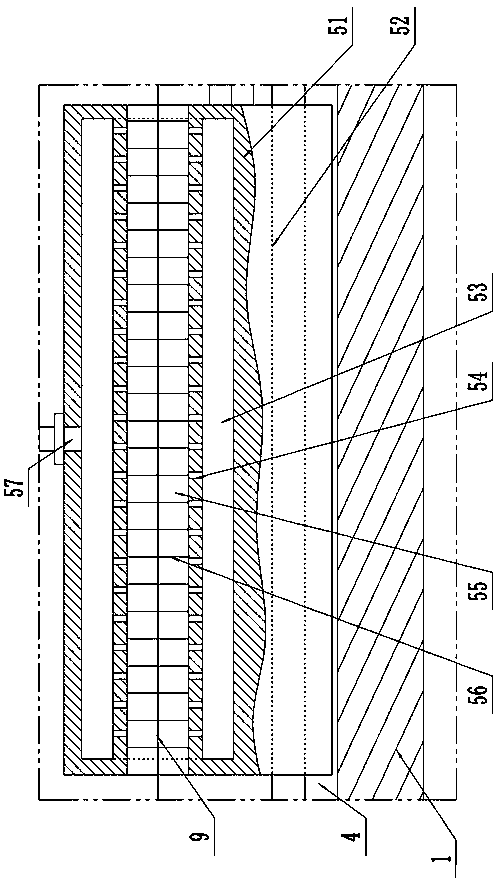

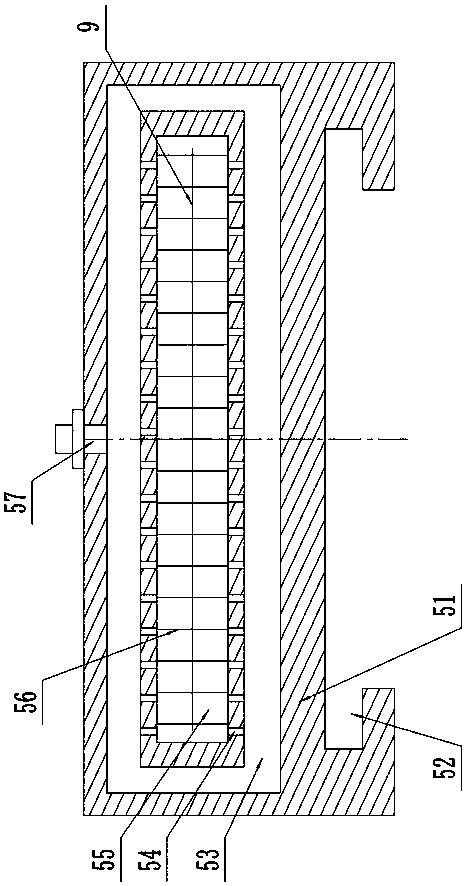

[0022] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a cleaning device for clothing surface accessories, including a casing 1, a cleaning chamber 2, a guide roller 3, a guide rail 4, a scrubbing device 5, a connecting pipe 6, a connecting shaft 7, Guide roller 2 8, connecting tank body 10, connecting pin 11, turntable 12, motor 1 13, fixed seat 14, guide roller 3 15, cleaning liquid housing 16 and water pump 17; the inside of the box body 1 is provided with a cleaning chamber 2 , the outer lower right side of the box body 1 is fixedly connected with a fixed seat 14; the guide rail 4 is horizontally fixedly connected to the center of the bottom surface of the cleaning chamber 2, and the guide rail 4 is horizontally movably connected with a scrubbing device 5; 3 and guide roller 2 8 are respectively located on the left and right sides above the guide rail 4, and the guide roller 1 3 and guide roller 2 8 are all movably connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com