Automatic bore scrubbing device and bore scrubbing system

A linkage device and drive device technology, which is applied in the direction of weapon cleaning devices, offensive equipment, weapon accessories, etc., can solve the problems of inability to clean, wear, and complete cleaning of the gun bore, and achieve high work efficiency, simple operation, and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The conception, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

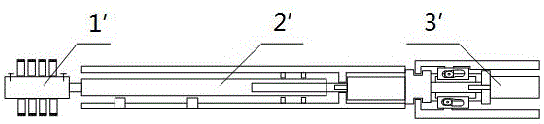

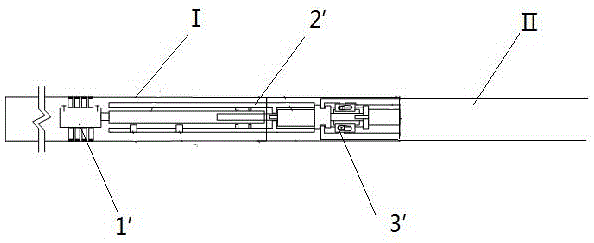

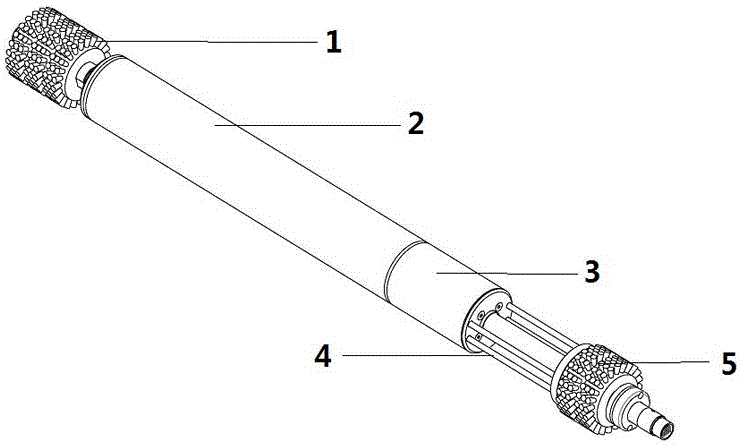

[0033] The gun bore scrubbing device of the best embodiment of the present invention is made up of first brush head device 1, reciprocating drive device 2, brake device 3, head and tail linkage device 4, tail brush head device 5, refer to Figure 3 to Figure 10 shown. The front end of the reciprocating drive device 2 is connected with the head brush head device 1 , and the other end thereof is connected with the tail brush head device 4 through the brake device 3 through the head and tail linkage device 4 . In the present invention, due to adopting the front brush head device 1 and the tail brush head device 5 at the same time, in the whole operation process, both front and back can be brushed at the same time at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com