A turbine blade probability damage tolerance analysis method

A turbine blade, damage tolerance technology, applied in the field of aero-engine structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

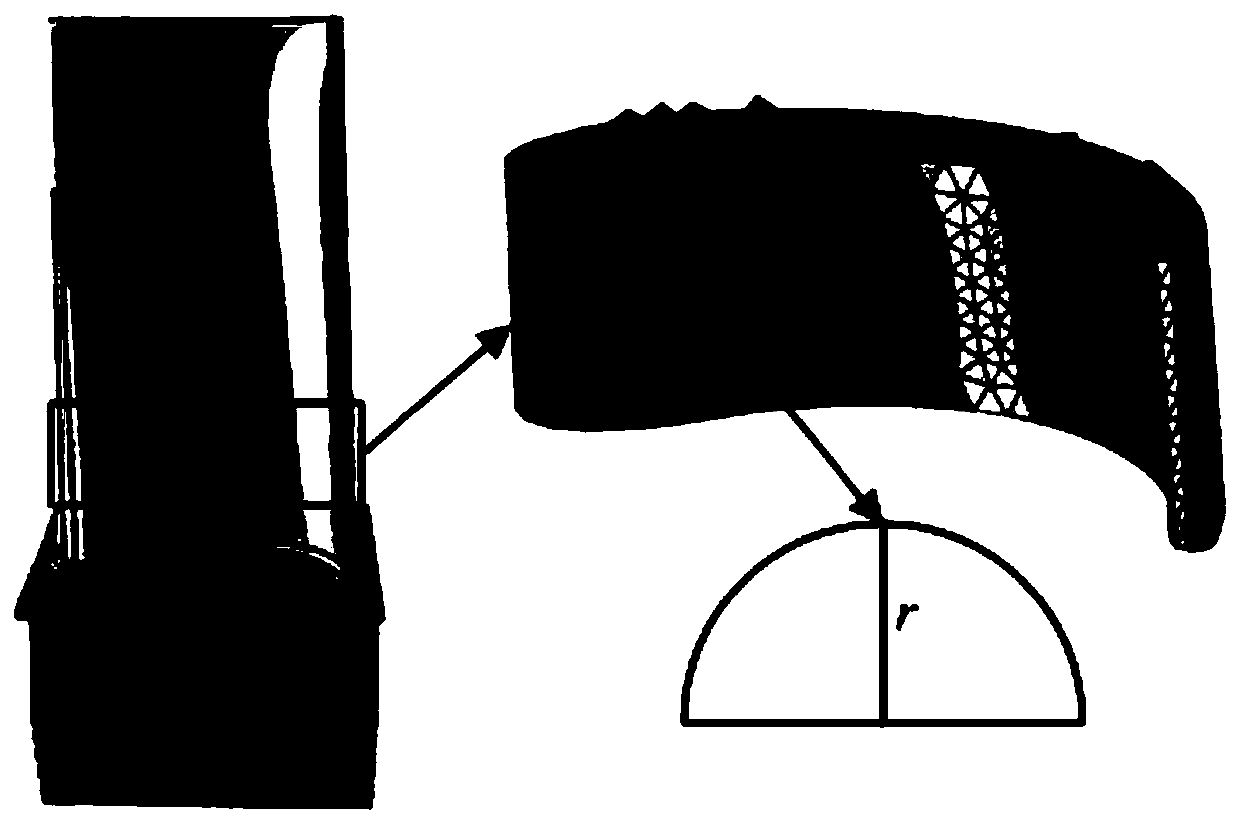

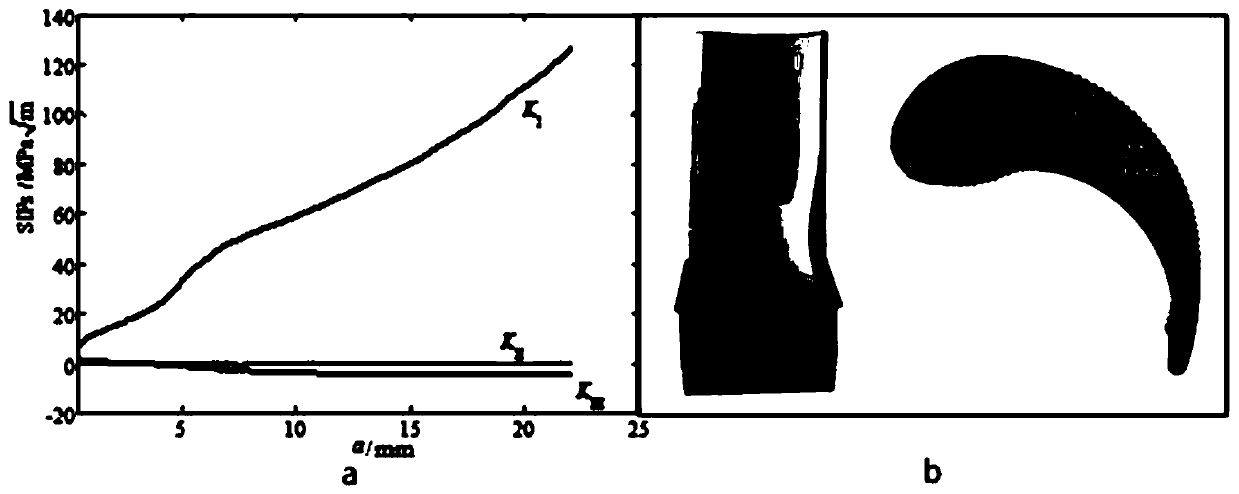

[0075] Step 1: Firstly, a deterministic three-dimensional crack growth analysis is carried out on the turbine blade. The overall finite element model of the blade and the local sub-model after the crack is introduced are as follows: figure 1 Shown: The model is 75.8mm long, 43.6mm wide, and 15.4mm thick. The finite element model contains 96287 C3D10 elements, 143824 nodes, the initial crack size is 0.5mm, the thrust is 544.1N, and the bending moment is 400Nm. The blade material is AISI450 steel, the crack growth rate constant C is 2.0349e-8, m is 3.45, and the fracture toughness is K IC for The invention uses the combination of Abaqus and Franc3d to analyze the deterministic crack growth of the turbine blade. Firstly, the global model of the blade is analyzed by Abaqus to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com