Method for analyzing damage tolerance of turbine blade interval

A technology of turbine blades and analysis methods, applied in the field of turbine blades, can solve problems such as lack of experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

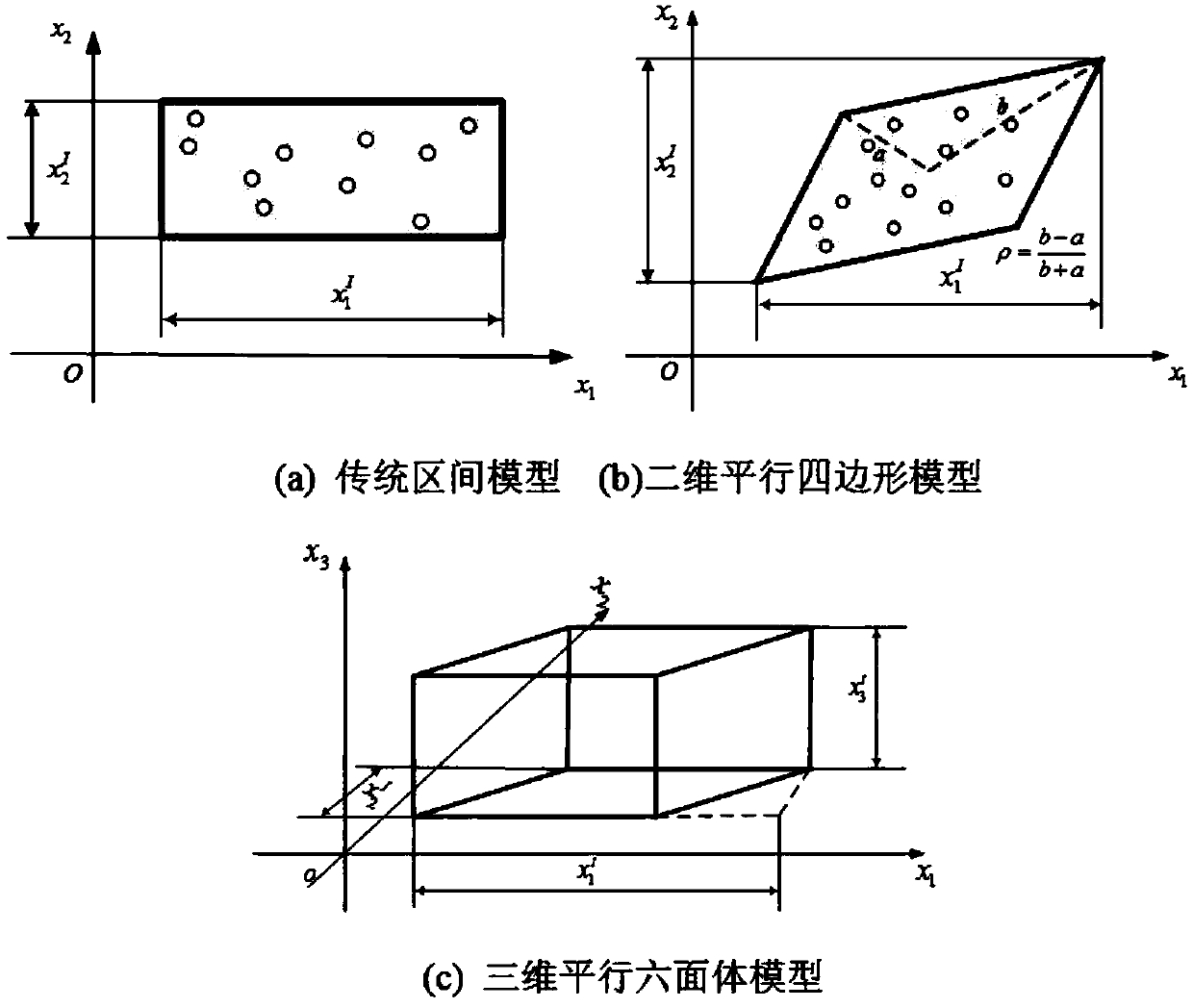

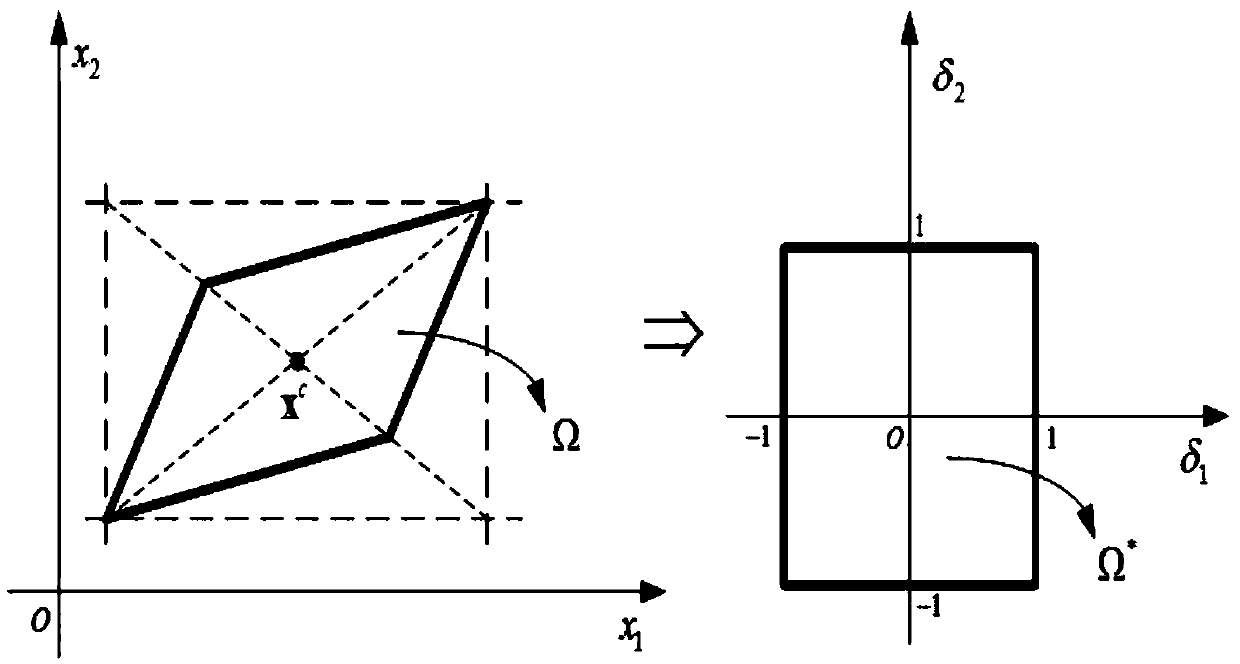

[0056] Aiming at the lack of samples, the invention proposes an interval analysis method for the crack propagation life. Since in the crack structure, some parameters are correlated, such as two crack growth rate constants, while some parameters are independent parameters, such as load and crack size, etc., a novel parallelepiped model is introduced in the method to simultaneously contain It is measured when the relevant interval parameters contain independent interval parameters. Through the parallelepiped model, most of the relevant interval parameters will be unified and normalized into an independent standard hypercube. In this standard space, the upper and lower boundaries of the fatigue crack growth life of the turbine blade are predicted by using the subinterval analysis method.

[0057] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

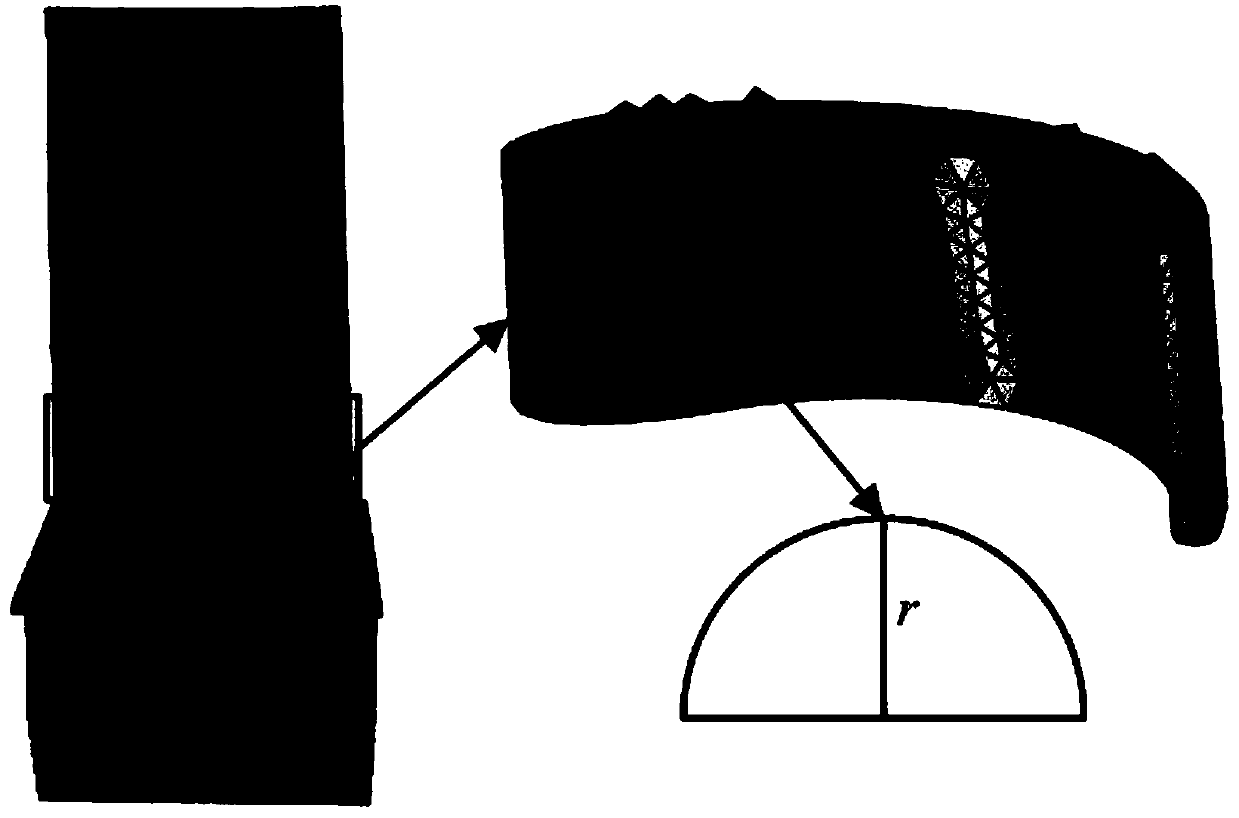

[0058] Step 1: Firstly, a deterministic three-dimensional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com