Automatic sawing equipment for straw macrofiber seedling growing rods

A long-fiber sawing technology, which is applied in mechanical equipment, sugarcane machining, etc., can solve the problems of seedling sticks being torn, yield decline, and inability to realize straw long-fiber seedling stick sawing, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

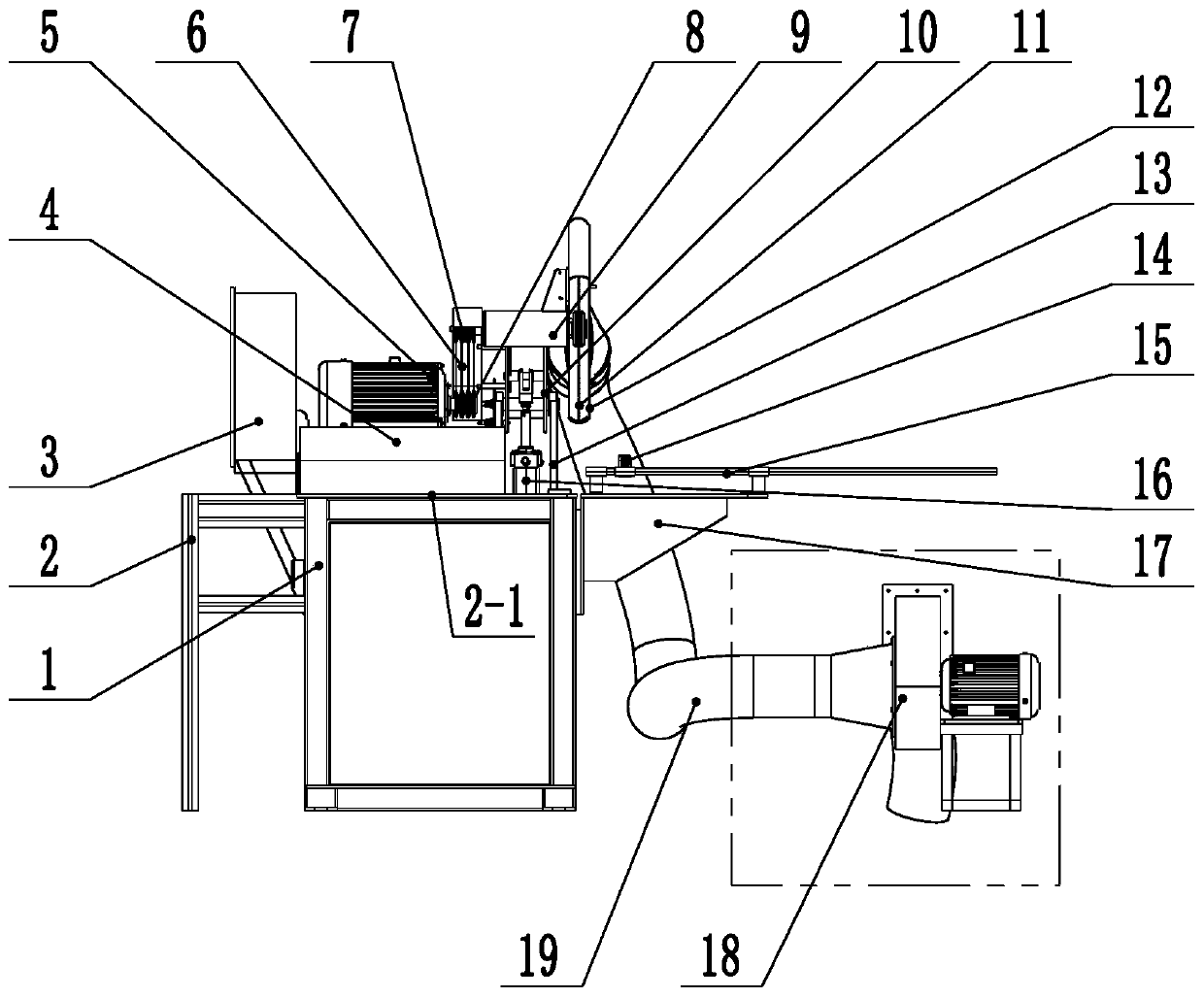

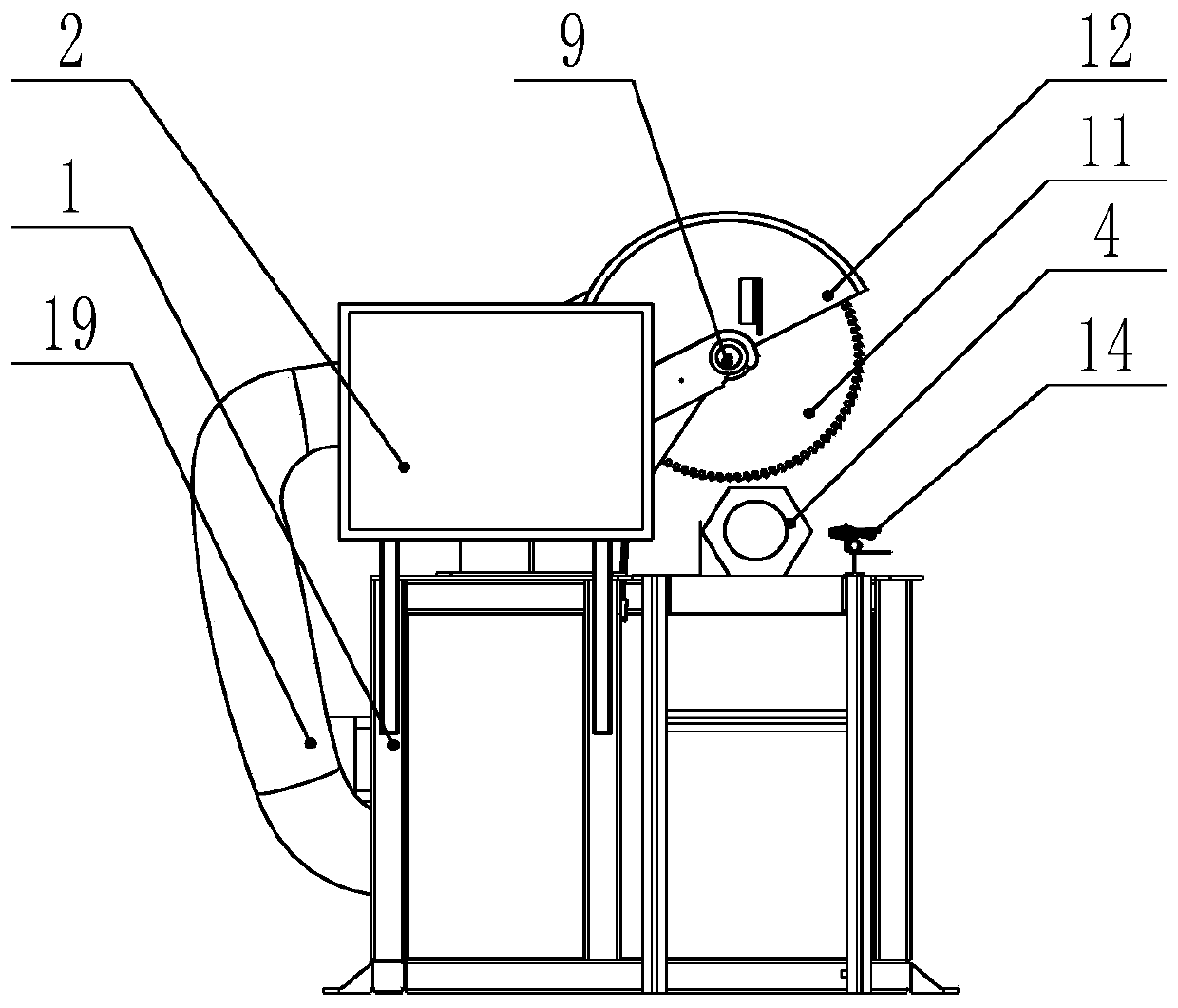

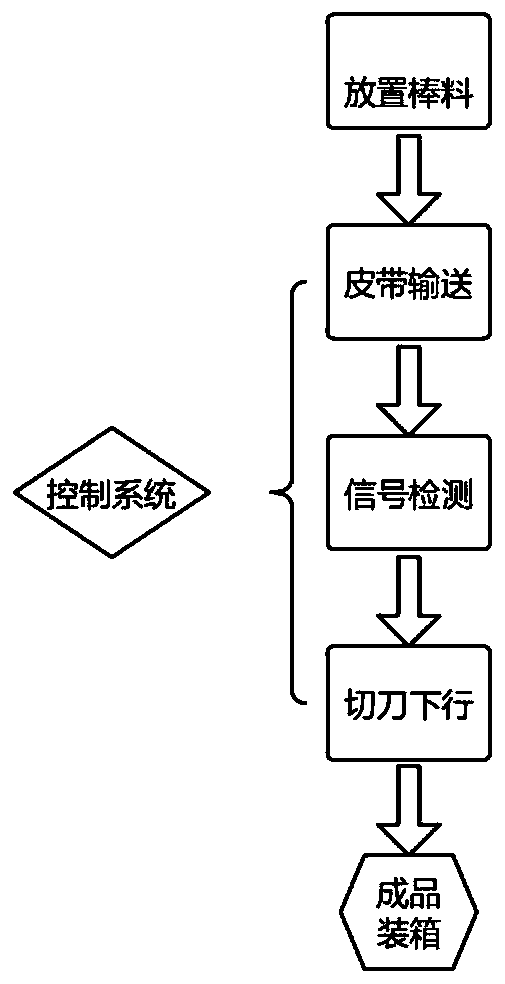

[0017] Such as figure 1 , figure 2 and image 3 As shown, an automatic sawing equipment for straw long-fiber seedling rods includes a sawing device assembly, a dust removal device, a control box 3, a power and transmission device, a material transmission device, a sawing length measuring device, and a frame 1. The feature is: the sawing device assembly includes a sawing shaft assembly 9, a sawing rotating frame 10, a saw blade 11, a saw blade guard 12 and a bearing seat 13; the sawing shaft assembly 9 is installed on On the sawing rotary frame 10, the sawing rotary frame 10 is fixed on the frame 1 by the cylinder 16, the saw blade 11 is installed on one end of the rotating shaft of the sawing shaft cylinder assembly 9, and the saw blade guard 12 is fixed On the outer cylinder of the sawing shaft assembly 9, the other end of the rotating shaft of the sawing shaft assembly 9 is connected with a sawing pulley 7;

[0018] The dust removal device includes a fan assembly 18 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com