Variable-speed automatic logistics device for dual-channel steering shuttle vehicles

A shuttle, dual-channel technology, applied in the field of automatic logistics devices for dual-channel steering shuttles, to achieve fast incoming and outgoing work, and quickly meet the effects of entering and leaving the warehouse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

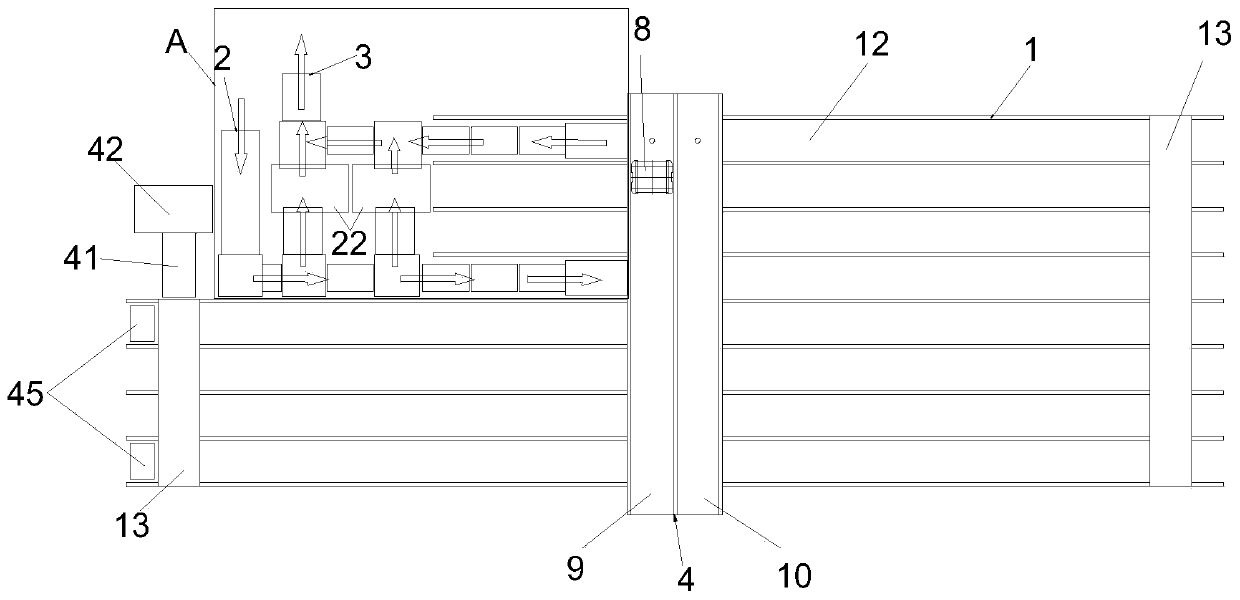

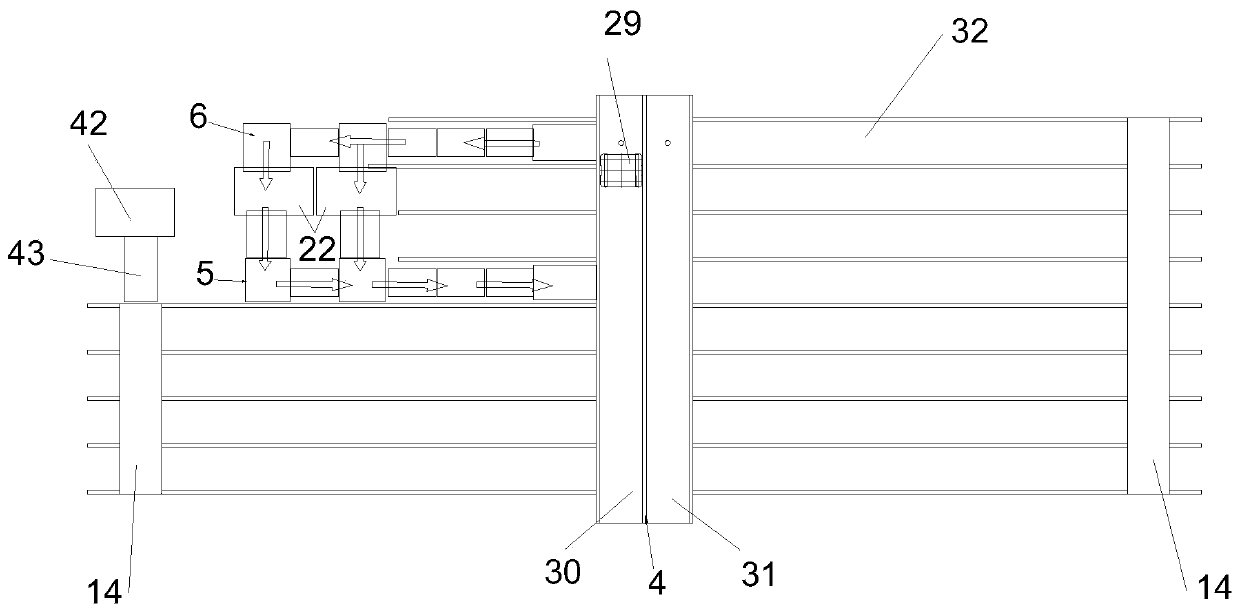

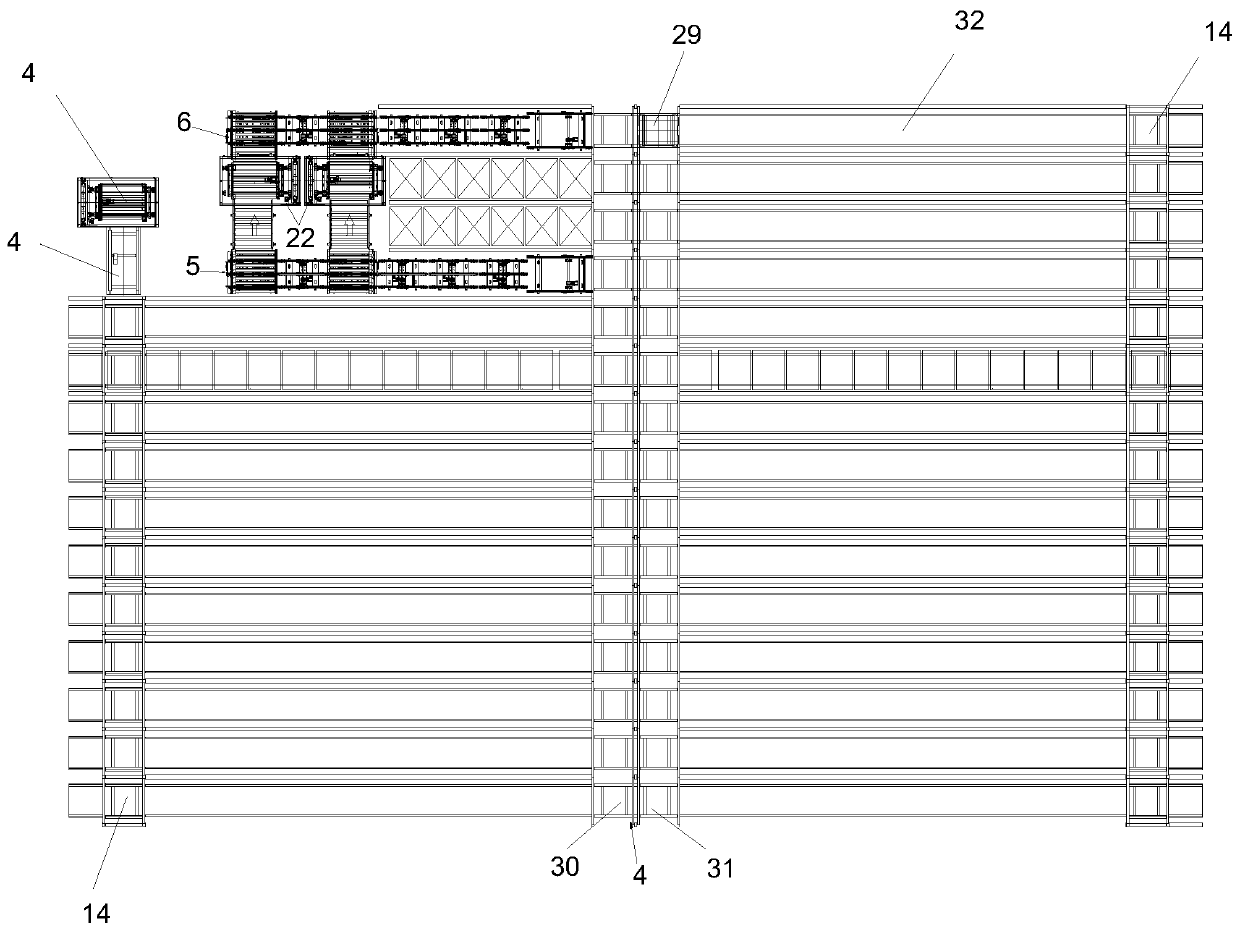

[0029] Such as Figure 1-4 As shown, the present embodiment provides a variable-speed dual-channel steering shuttle car automated logistics device, including storage shelves 1, incoming conveyor lines 2 (5), outgoing conveyor lines 3 (6), and steering shuttle cars 8 (29 ) (there are N shuttle cars, only two are shown in the present embodiment, the ground floor and the Nth floor), turning to the shuttle car changing layer lifting device 42, the storage shelf 1 is multi-layer, and the storage shelf 1 on each floor 1 is provided with a shuttle shelf storage vertical laneway 12 (32) for the steering shuttle car 8 (29) to walk and a steering shuttle car conversion track 13 (14). To the penultimate nth storage position on both sides of the roadway 12 (32), here is the penultimate 2nd or penultimate 3rd storage place, and one end of the steering shuttle car conversion track 13 (14) on the side is connected to the steering shuttle The car layer-changing lifting device 42 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com