Keel connector and preparation method thereof

A connecting piece and keel technology, which is applied in building components, buildings, building structures, etc., can solve the problems of poor structural stability and high production cost of keel connecting pieces, and achieve the goal of reducing production costs, improving structural stability, and facilitating connection operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

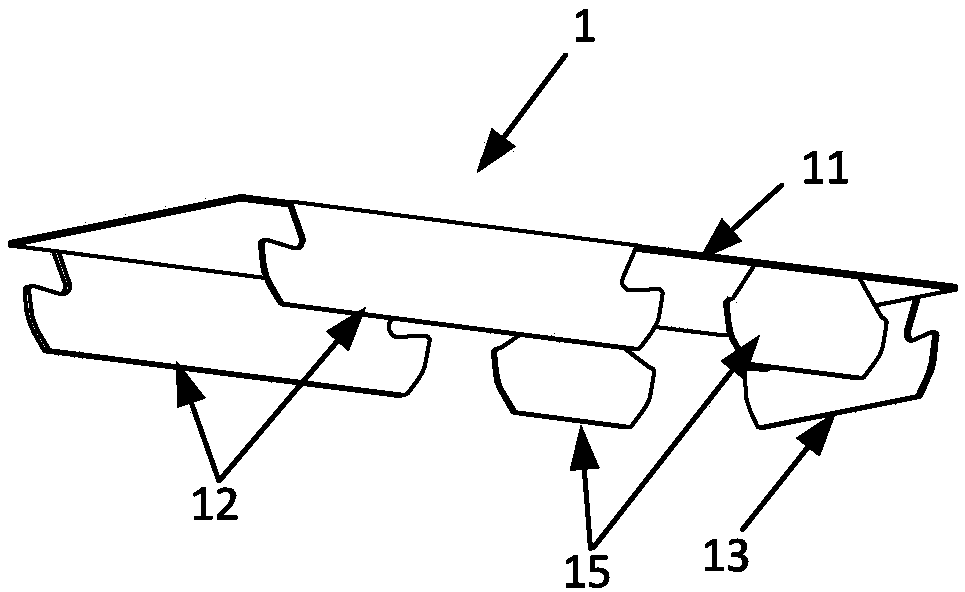

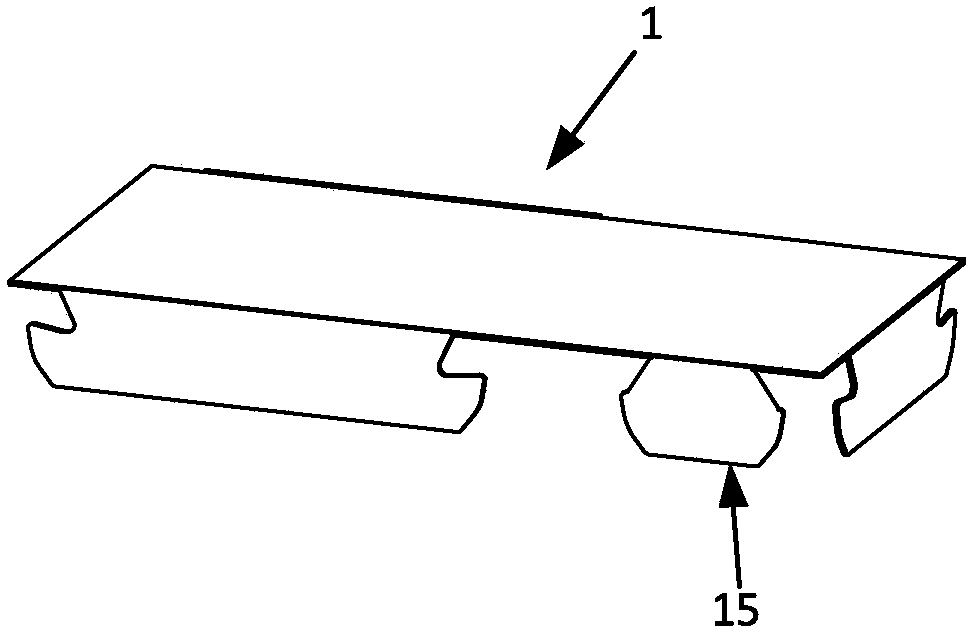

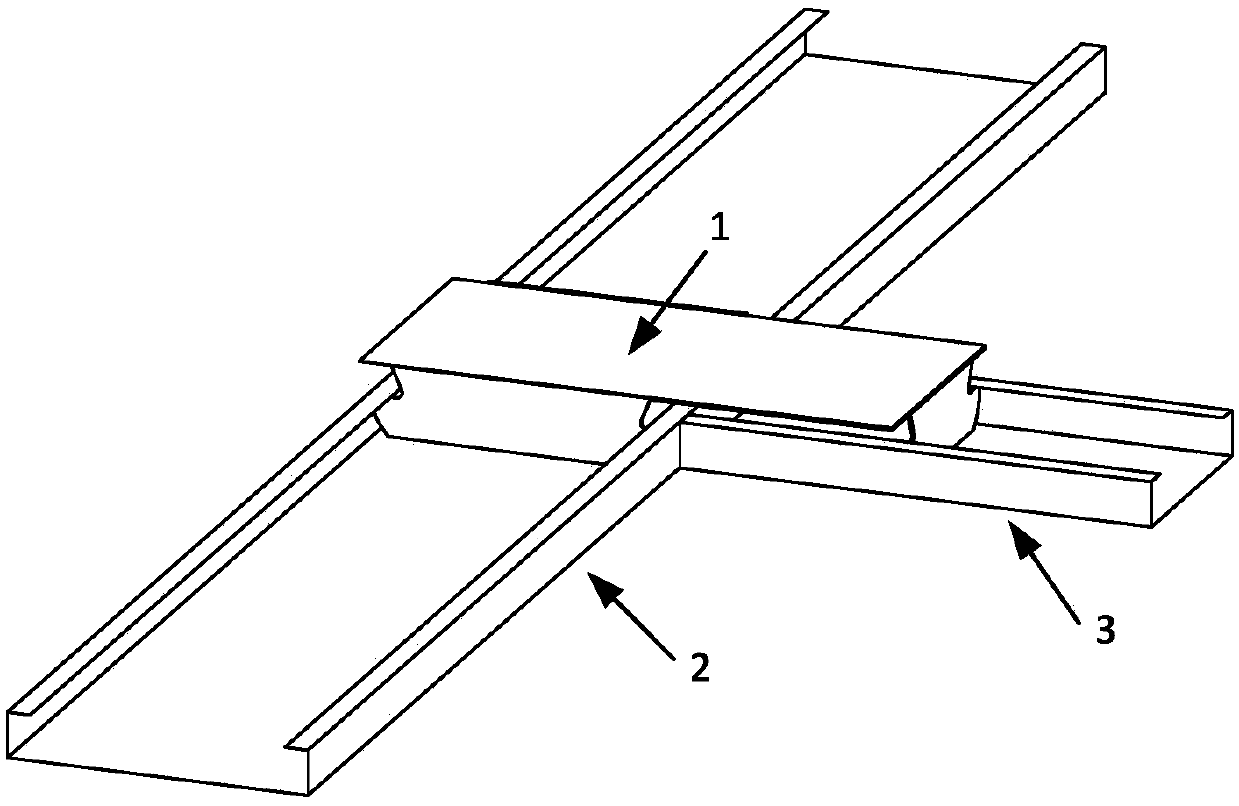

[0045] combine figure 1 , figure 2 , image 3 As shown, Embodiment 1 of the present invention provides a keel connector 1, including a connecting base plate 11, and also includes a first clamping portion 12 for connecting the first keel 2 and a second clamping portion for connecting the second keel 3. The connecting portion 13, the second keel 3 is arranged on one side of the first keel 2 and is perpendicular to the first keel 2.

[0046] In this embodiment, the first clamping portion 12 includes two clamping plates arranged on the first side of the connection substrate 11 and on the opposite side of the first side, and the two clamping plates are arranged in parallel and perpendicular to the connection substrate 11 ; In the specific operation, the above two clamping plates can be inserted into the C-shaped groove of the first keel 2 at the same time, so as to realize the effective clamping operation of the first keel 2; the above connection operation is simple and easy, sa...

Embodiment 2

[0058] Embodiment 2 of the present invention provides a keel connector 1. The main structure is similar to that of Embodiment 1, and also includes a connecting base plate 11, a first clamping portion 12, and a second clamping portion 13; specific settings for the main structure Please refer to the description in Embodiment 1, which aims to illustrate the difference between the two.

[0059] combine Figure 5 , Image 6 as well as Figure 7 As shown, the keel connector 1 in this embodiment also includes a third clamping portion 14 and a third limiting portion 16 for connecting the third keel 4, and the third keel 4 is arranged on the other side of the first keel 2. side and perpendicular to the first keel 2. In specific operation, the third clamping portion 14 includes a clamping plate arranged on the opposite side of the second side of the connection substrate 11, the third clamping portion 14 is perpendicular to the connection substrate 11; the above-mentioned one clamping...

Embodiment 3

[0064] Embodiment 3 of the present invention provides a preparation method of the keel connector applied in Embodiment 1 or Embodiment 2, which includes the following steps: on the first side of the connecting substrate and on the opposite side of the first side, a Clamping the clamping plate of the clamping groove, bending the clamping plate on the first side and the clamping plate on the opposite side of the first side by 90° to form the first clamping portion;

[0065] A clamping plate with a clamping groove is provided on the second side of the connecting substrate, and the clamping plate on the second side is bent by 90° to form a second clamping portion;

[0066] A limiting plate is provided on the first side of the connecting substrate and on the opposite side of the first side, the limiting plate is arranged between the first clamping part and the second clamping part, and the limiting plate is bent at a preset angle, To form the second limiting part.

[0067] In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com