Extrusion runner improved structure of plastic extruder

A plastic extruder and extruder technology, which is applied in the field of improving the structure of the extrusion channel of the plastic extruder, can solve the problems of inconvenient connection, large resistance, and inconvenient material flow, etc., so as to achieve fast and convenient connection operation, increase The effect of increasing the amount of material extruded and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

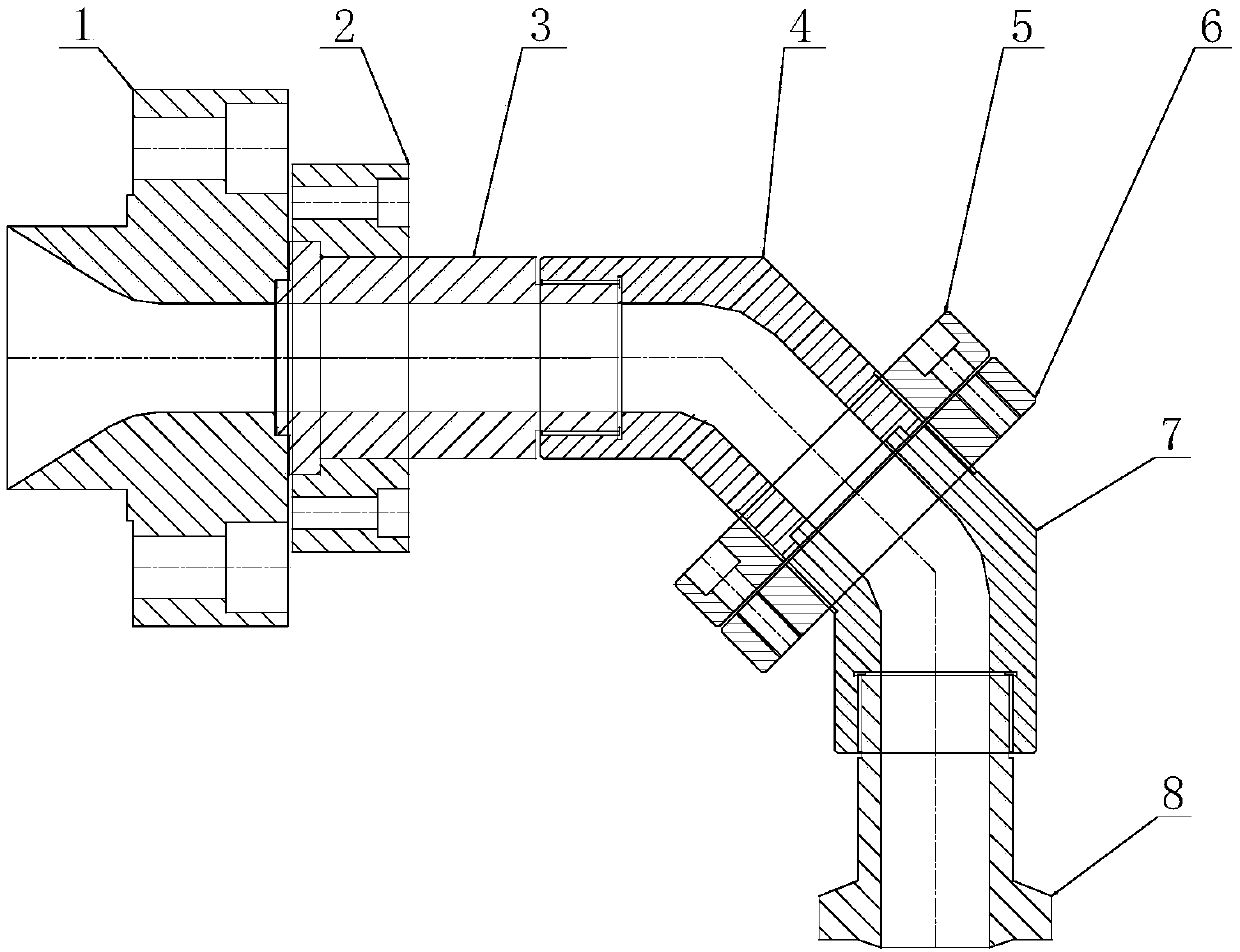

[0012] see figure 1 , the improved structure of the extrusion flow channel of the plastic extruder, including the first connecting part 1 connected to the discharge port of the extruder, the flow channel body 3, the first elbow 4, the second elbow 7 and the connection with the machine head The second connection part 8 . The first connecting part is connected to the flow channel body 3 through the clamping block 2 and bolts, so as to prevent material leakage at the connecting part of the two. The other end of the runner body 3 is threaded to the first elbow 3, the first elbow is threaded to the first flange 5, the second elbow is threaded to the second flange 6, and the first method The flange and the second flange are fixed by fastening scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com