Fluid pipeline adapter substitute

A technology for conversion joints and fluid pipelines, which is applied in the direction of pipes/pipe joints/fittings, sealing surface connections, passing components, etc., which can solve problems such as fractures and safety accidents, and achieve the effects of sealing and convenient connection operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

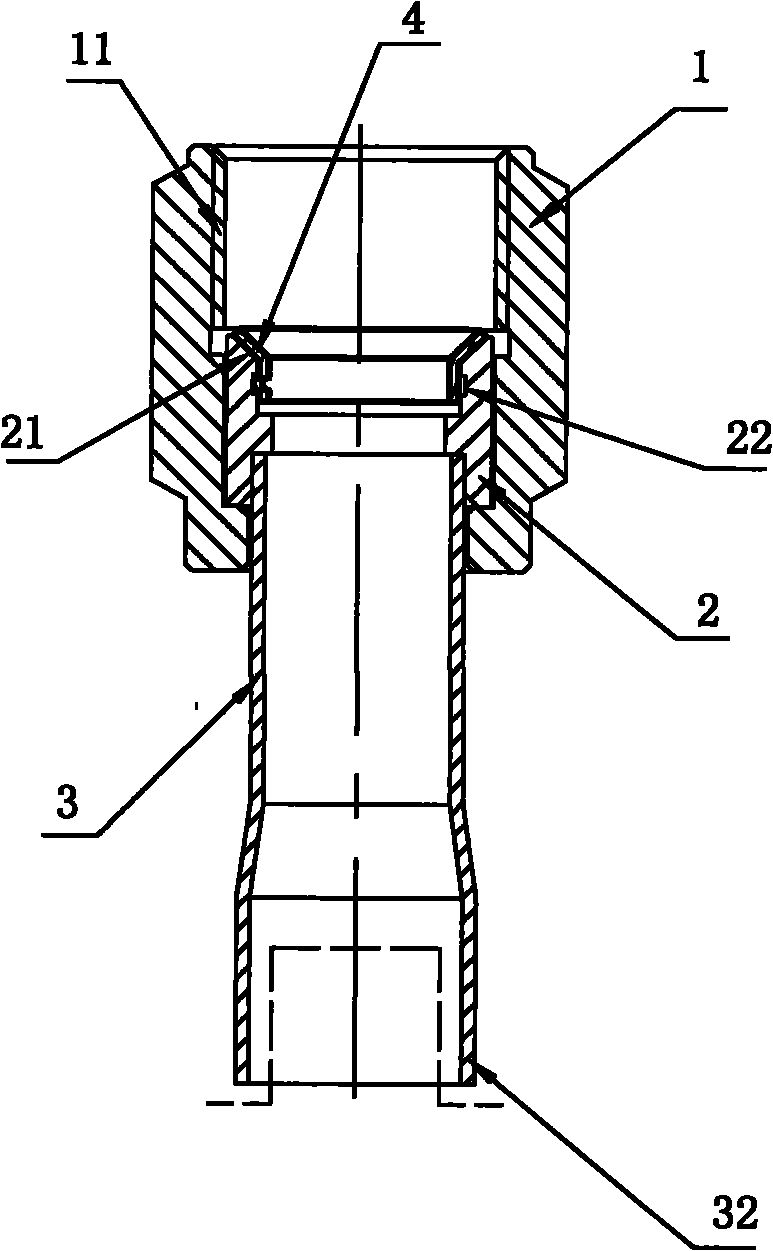

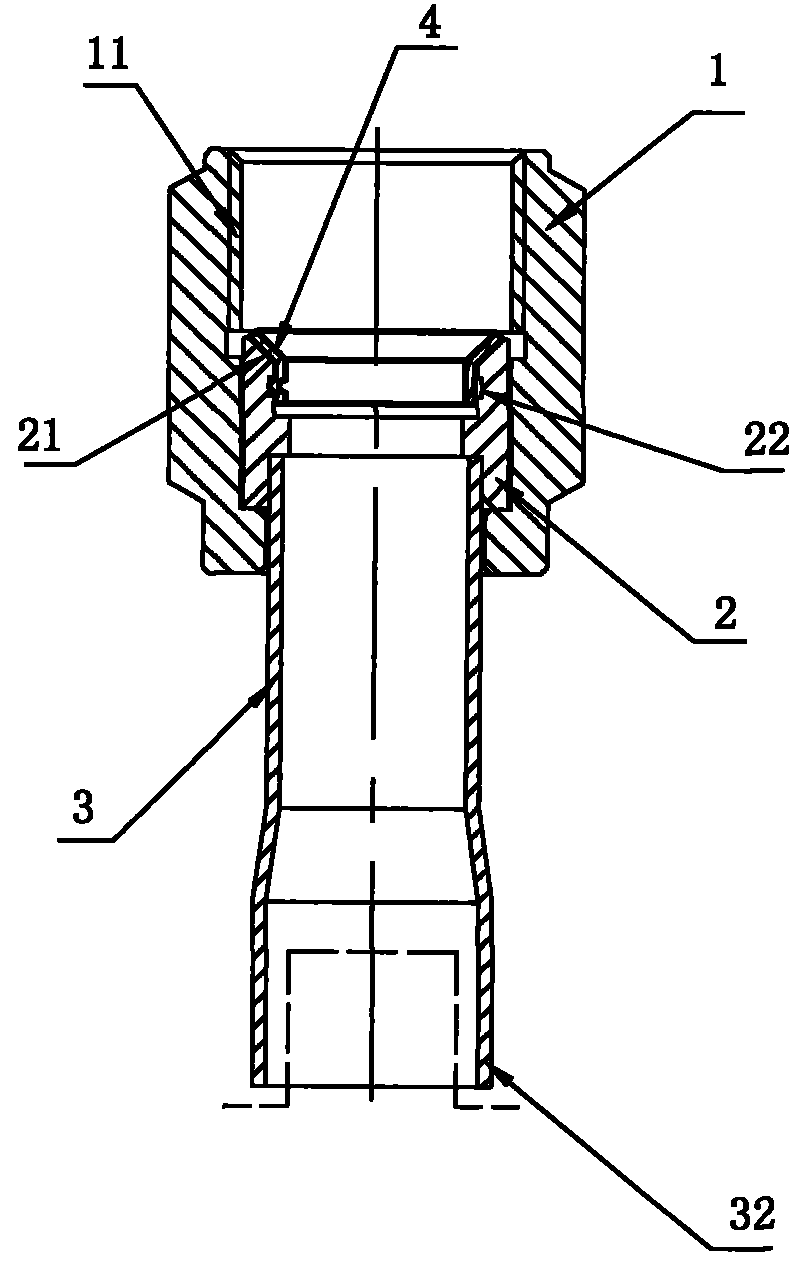

[0011] Refer to attached figure 1 , 2 .

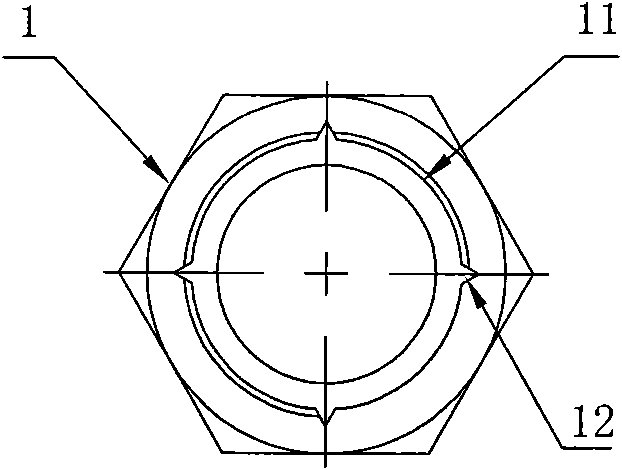

[0012] This embodiment includes a joint nut 1, a joint core 2, and a connecting pipe 3 connected to one end of the joint core 2. The joint core 2 is provided with a gasket 4 at the other end connected to the connecting pipe 3. The inner ring of the joint nut 1 The thread 11 is provided with an air guide groove 12, and the connecting pipe 3 and the gasket 4 are respectively provided at both ends of the joint core 2.

[0013] The joint core 2 is also provided with a tapered mouth 21 at the other end connected to the connecting pipe 3, and the lower part of the tapered mouth 21 is provided with a card slot 22, and the gasket 4 can be inserted into the tapered mouth 21 , and snapped into the card slot 22.

[0014] The number of the air guide grooves 12 is four, and they are uniformly distributed along the inner thread 11 of the joint nut 1 in the circumferential direction, and the cross section of the air guide grooves 12 is inverted "V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com