Double-sealing high-temperature high-pressure elastic ball valve seat structure

A high-temperature, high-pressure, double-sealing technology, applied to valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as valve safety and medium leakage, which is beneficial to sealing, ensuring safety and reducing risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

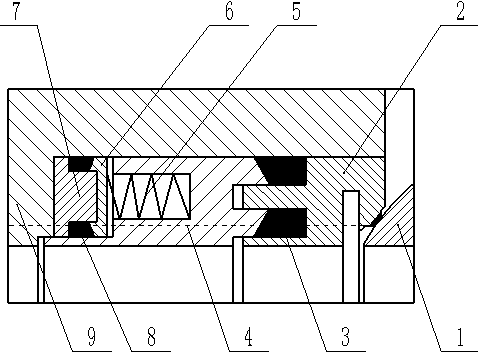

[0008] Such as figure 1 As shown, a double-seal high-temperature and high-pressure elastic ball valve seat structure includes a ball, a valve seat, a sealing ring I, a sealing ring II, a spring seat, a spring, a pressure ring, a pressure sleeve, and a valve body. The valve seat abuts on the ball There is a deep groove at the end, and the valve seat is provided with two concentric sealing rings I, and the sealing ring I is fixed by a spring seat, and a spring is installed on the spring seat, and the spring is pressed against the pressure ring. Two concentric sealing rings II are arranged between the pressure ring and the pressure sleeve, and the pressure sleeve is in contact with the valve body.

[0009] Working principle: When the valve is closed, the two concentric sealing rings II between the pressure ring and the pressure sleeve and the sealing ring I at the lower end of the valve seat act as the first seal. When the first seal fails, the sealing ring I at the upper end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com