Omni-directional traction electric door

An electric door and electric technology, applied in the direction of gate/door, door/window accessories, power control mechanism, etc., can solve the problems of door frame lifting dead point, small space occupation, and inability to close the door smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

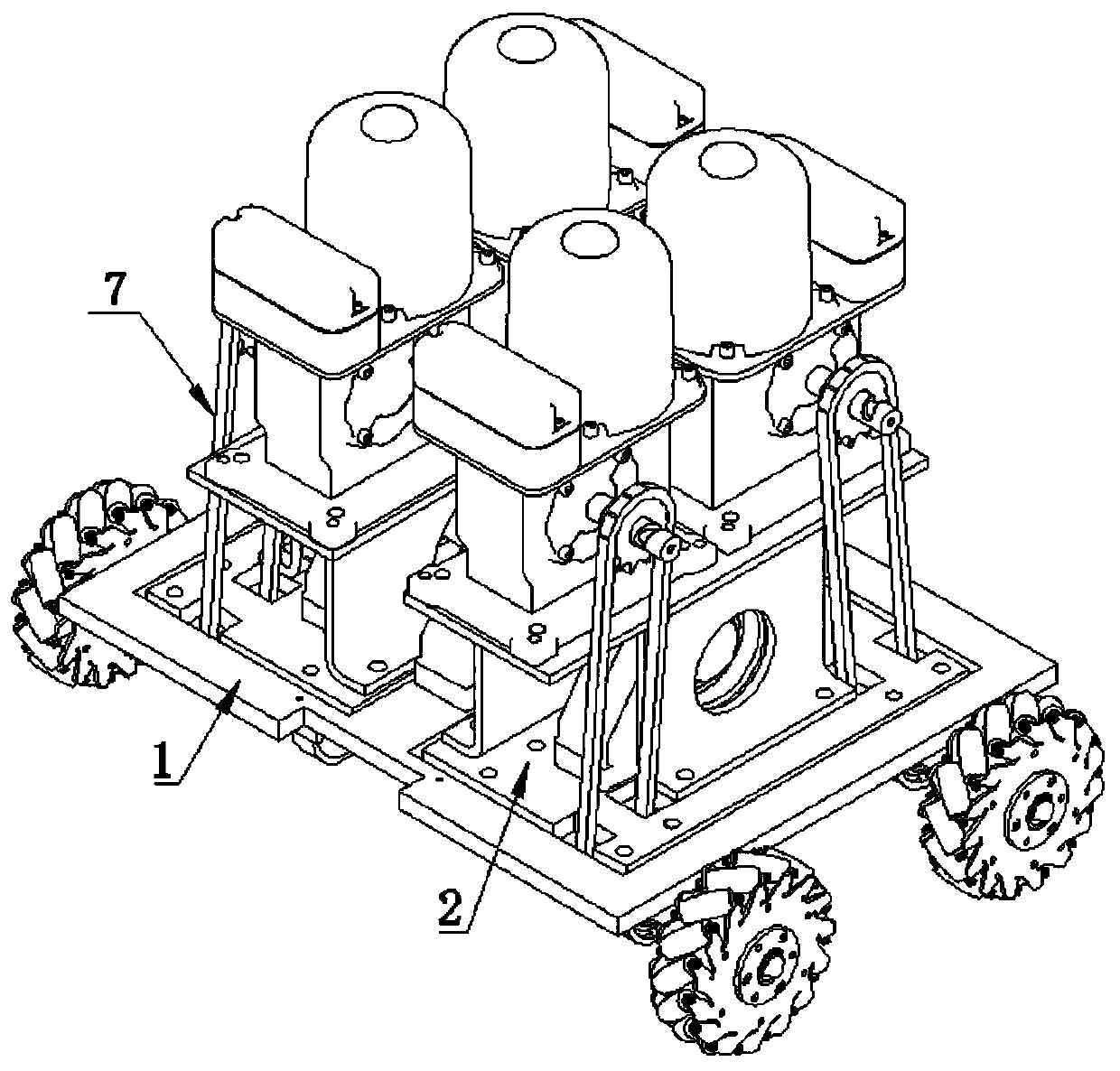

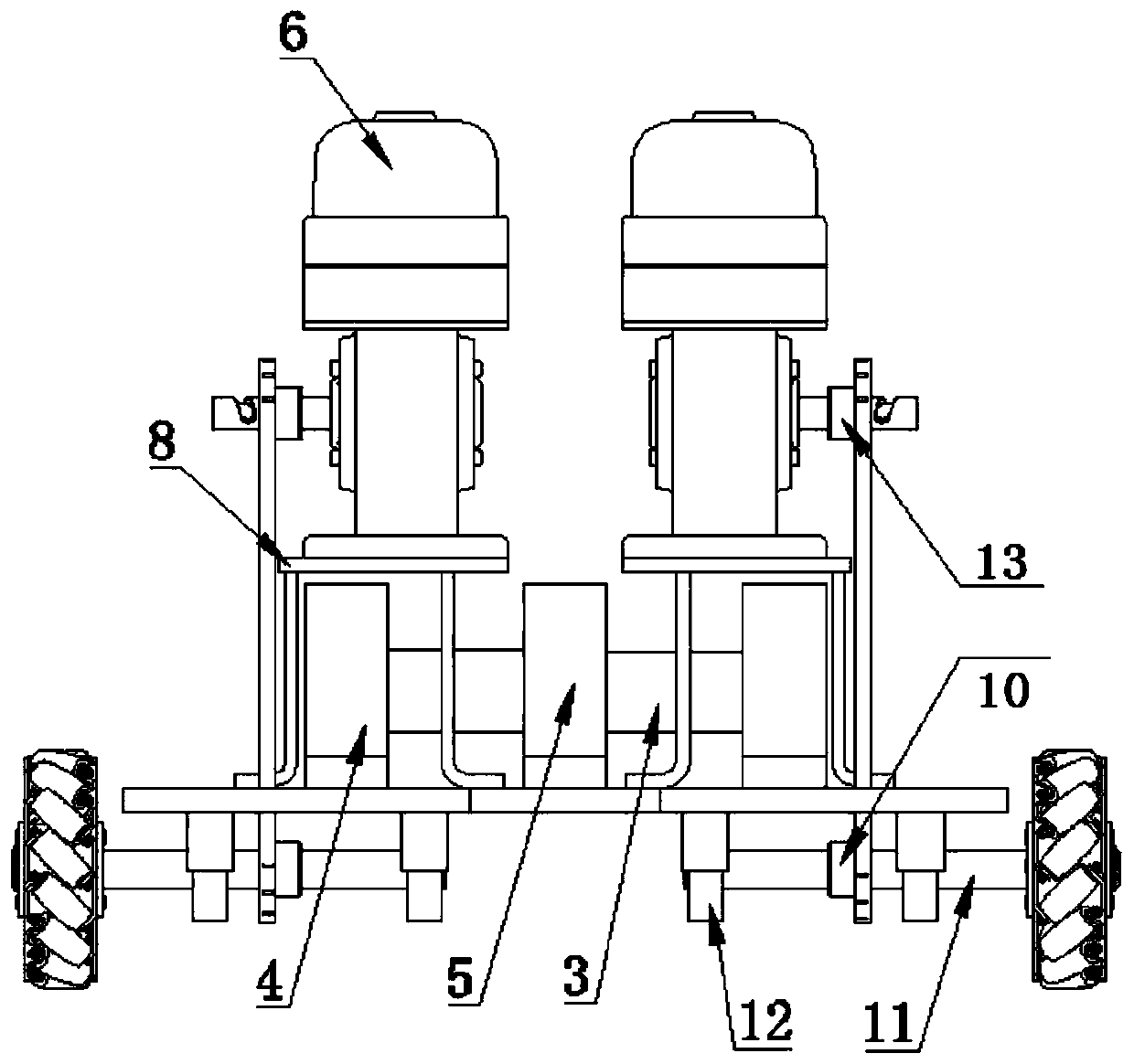

[0038] A kind of omnidirectional traction mechanism structure form of the present invention is introduced in this embodiment, see figure 1 and figure 2 , the base plate assembly includes a support base plate 1 and a head base plate 2, the support base plate 1 is fixedly arranged at the lower end of the machine head housing, a pair of long grooves are opened on the support base plate 1, and two pieces of machine head base plates 2 are respectively arranged in the long grooves, A bearing fixing frame 5 is arranged in the center of the support base plate 1, and a rotating shaft support 4 is arranged on the two machine head base plates 2. The two ends of the machine head bottom plate 2 can be turned up and down relative to the plane of the support bottom plate 1 through the bearings passing through the bearing fixing frame 5; the mecanum wheel assembly includes four sets of independent mecanum wheel units, each Both ends of the bottom plate 2 are provided with a group of indepen...

Embodiment 2

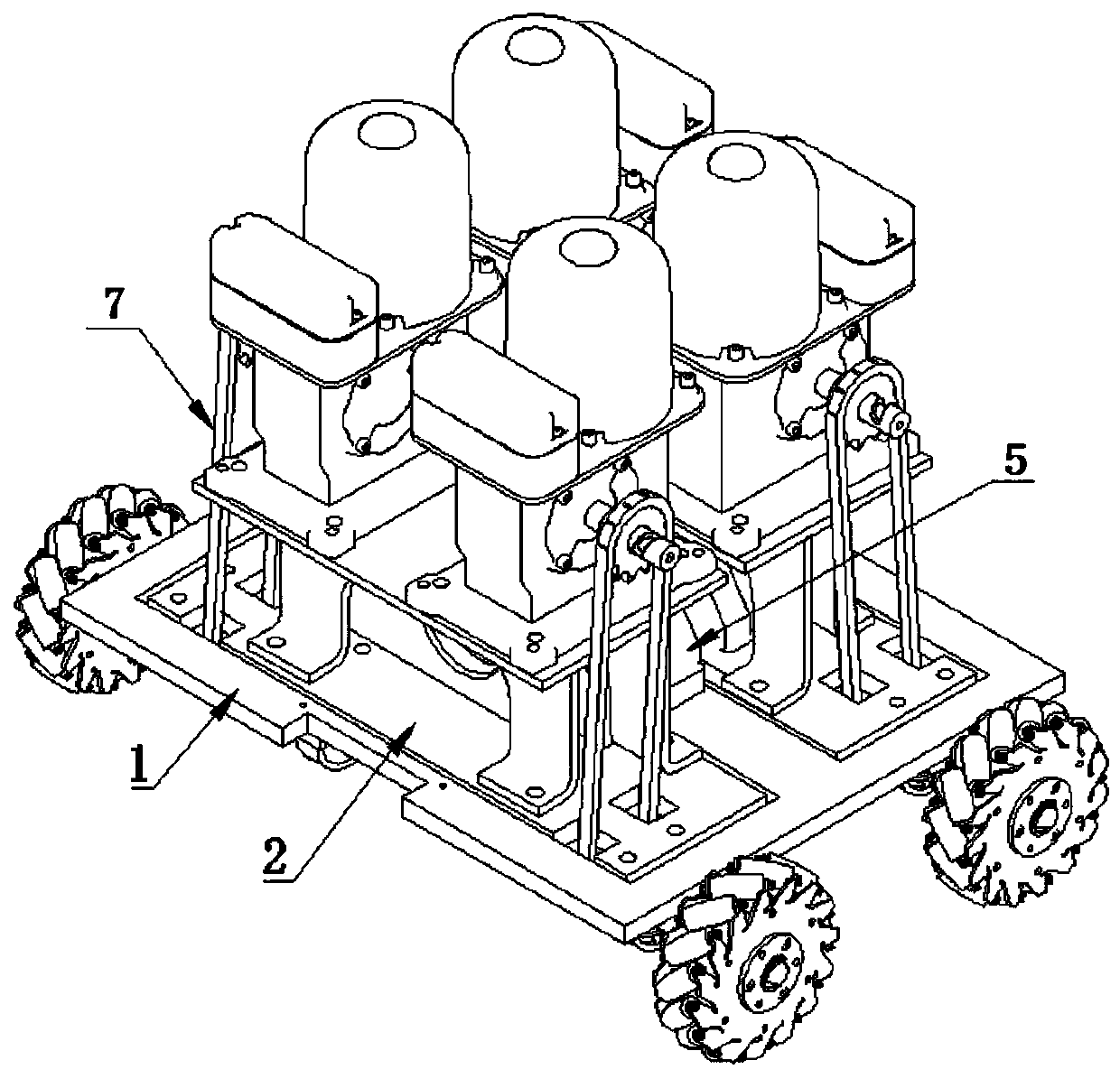

[0042] Another omnidirectional traction mechanism structural form of the present invention is introduced in this embodiment, see image 3 and Figure 4, and the difference from Embodiment 1 is that two head base plates 2 are arranged laterally, and two sets of mecanum wheel units on the same side along the horizontal axis of the support base plate 1 are arranged on one head base plate 2 . When the four sets of mecanum wheel units pass through rough and uneven roads, the nose base plate 2 can deflect at a certain angle to always ensure that the four sets of mecanum wheel units can be in close contact with the ground and will not hang in the air, so that the nose can be accurately Omni-directional movement, the door can be opened and closed smoothly.

Embodiment 3

[0044] The selection of the door body in this embodiment is an electric telescopic door body, see Figure 5 , including machine head, door body and fixed shaft, the machine head is fixedly connected with the door body, the tail of the door body is hinged with the fixed shaft, and the machine head with door body can rotate around the fixed shaft. The omnidirectional traction mechanism is installed in the machine head. When the machine head drives the door body to stretch, the electronic control system controls the traction mechanism in the machine head to move horizontally to the left to complete the door closing action, such as Figure 5 As shown; when the machine head drives the door body to retract, the electronic control system controls the traction mechanism in the machine head to move horizontally to the right to complete the door opening action, as shown in Figure 6 As shown; at this time, the electric telescopic door as a whole is still within the range of the passage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com