Central air conditioning unit with 0 to 100% output load regulation capability and control method

An air conditioning, central air technology, applied in energy-saving heating/cooling, shielding with air flow, refrigerators, etc., can solve problems such as difficulty in reducing load, frequent startup and impact on the power grid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

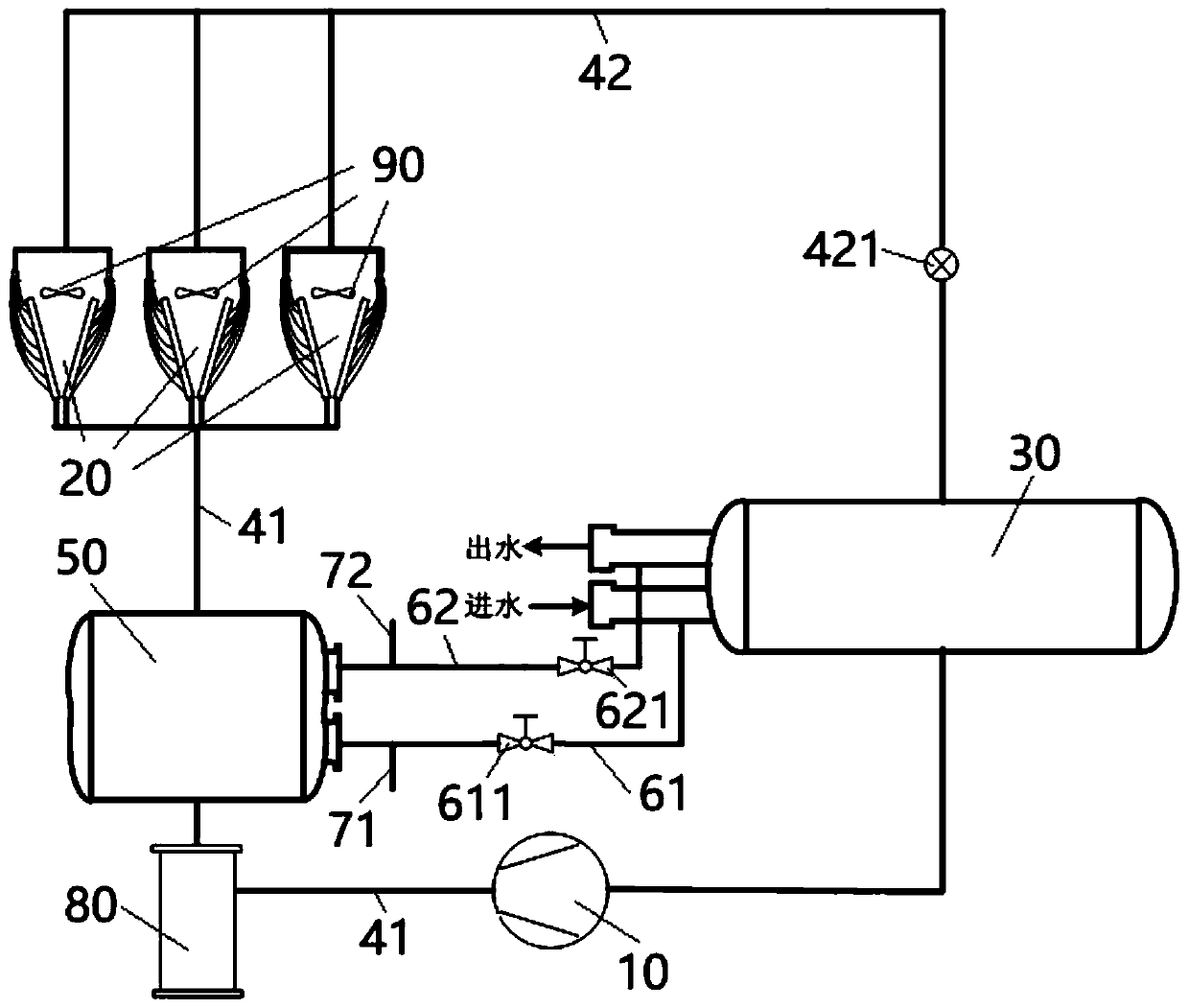

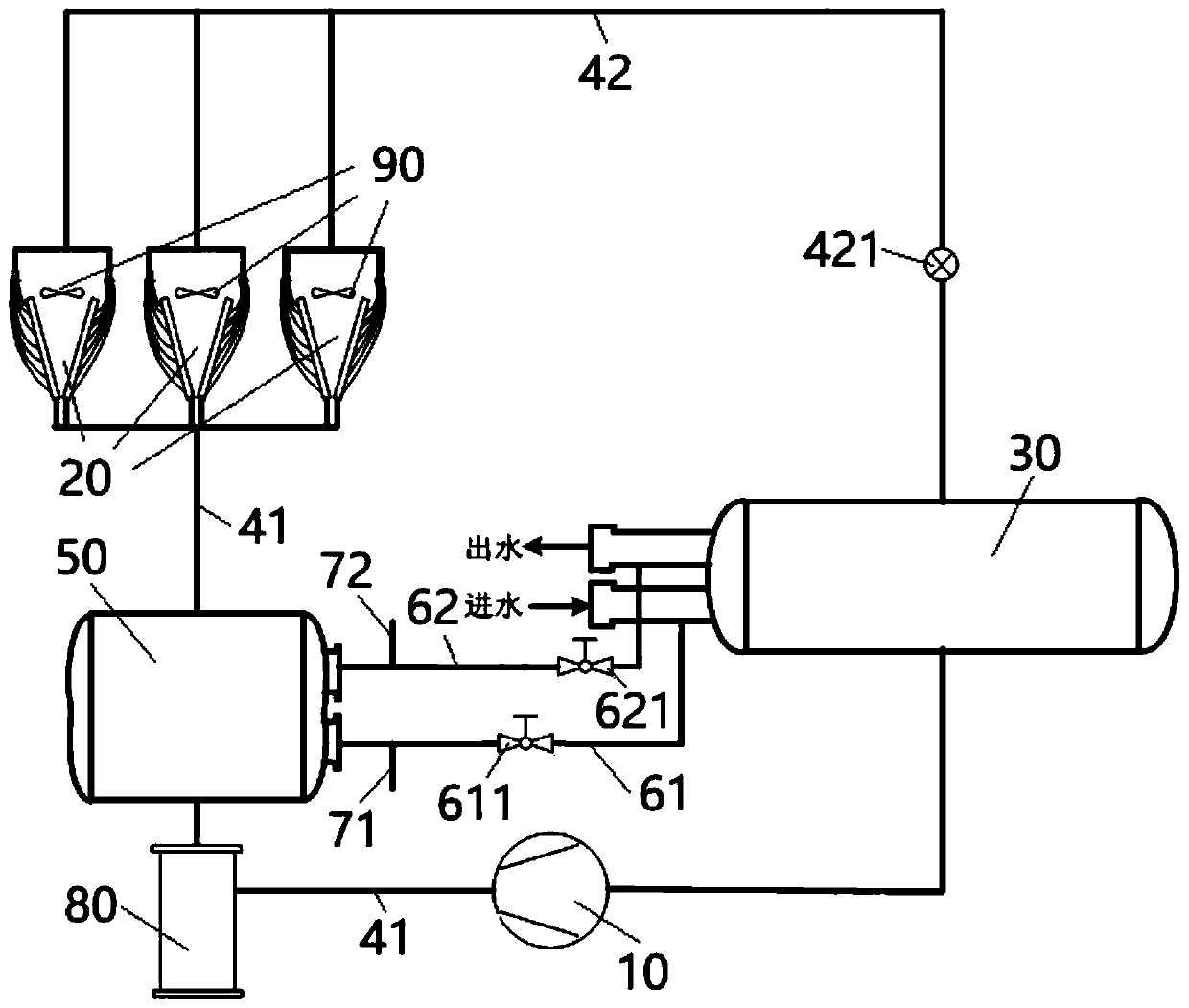

[0022] figure 1 An embodiment of the central air-conditioning unit with 0-100% output load regulation capacity of the present invention is shown, and the central air-conditioning unit includes a compressor 10 , a condenser 20 , an expansion valve 421 and a shell-and-tube evaporator 30 . The exhaust end of the compressor 10 is connected to the condenser 20 through a first pipeline 41, the condenser 20 is connected to the first refrigerant interface of the shell-and-tube evaporator 30 through a second pipeline 42, and the second refrigerant of the shell-and-tube evaporator 30 The interface is co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap