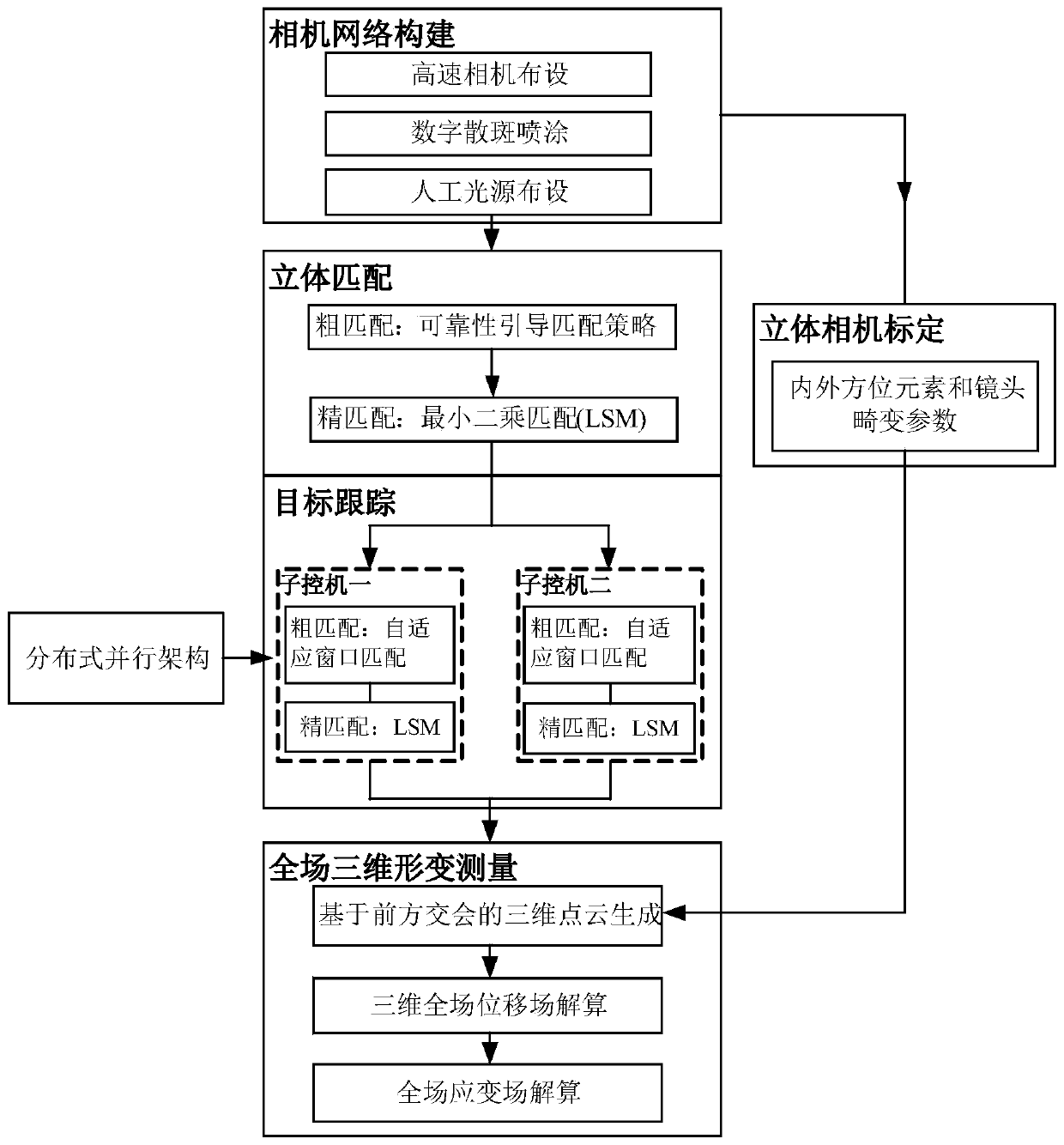

Digital speckle full-field deformation measurement method based on adaptive window matching

An adaptive window and digital speckle technology, applied in the field of computer vision, can solve the problems of sudden changes in stereoscopic image parallax, and the measurement of fine deformation of speckle image sequences cannot be directly applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

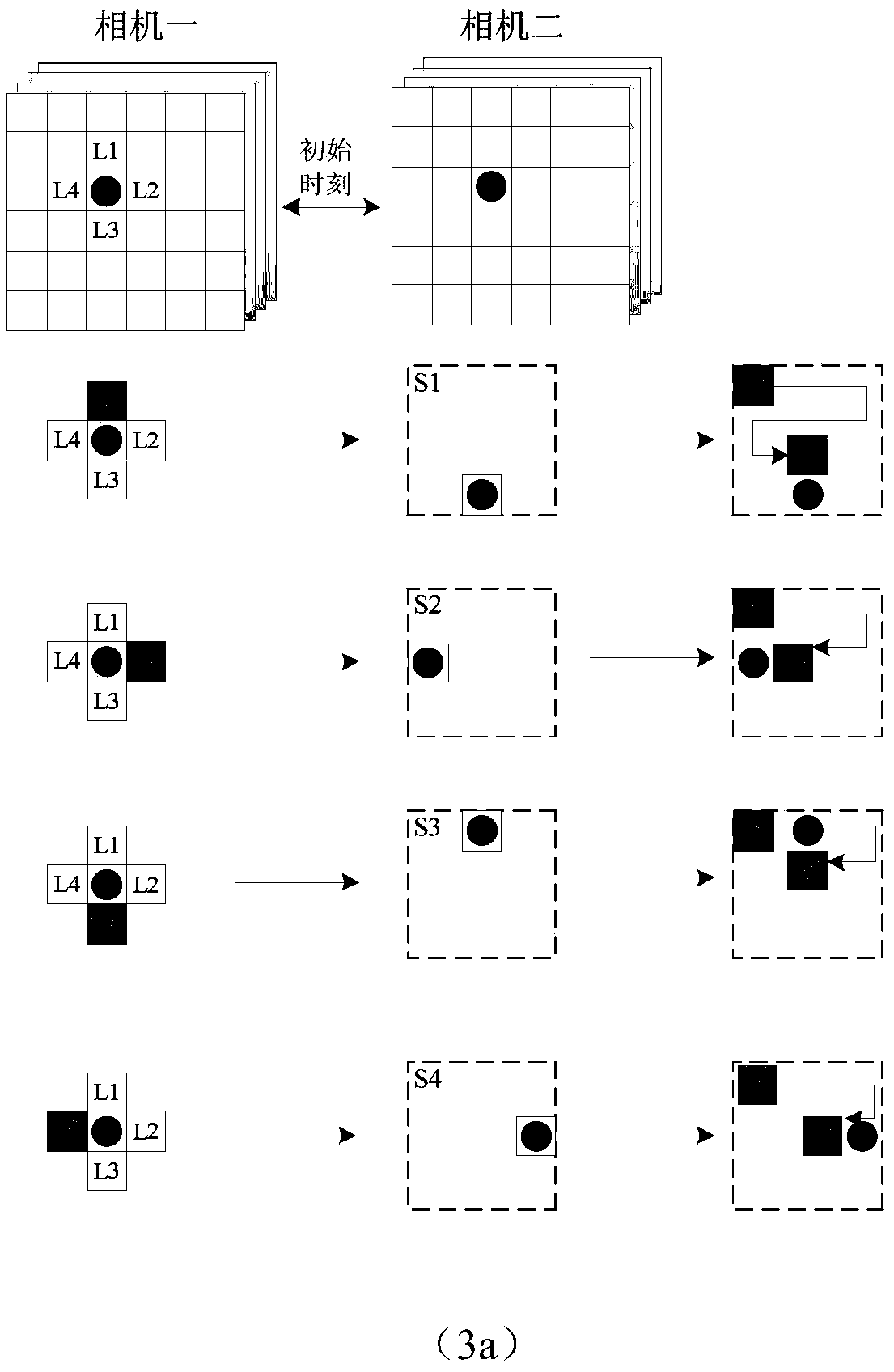

Method used

Image

Examples

Embodiment

[0076] Simulation test: Gaussian speckle simulation experiment is used in this example

[0077] In order to verify the image matching strategy of this patent, robust speckle features and accurate deformation information can be provided through simulated images. Based on formula (4), the speckle simulation image can be generated by Gaussian random speckle. Among them, the initial speckle image is generated according to random speckle position and speckle radius, and the deformed speckle image is formed by setting different deformation parameters on the initial image.

[0078]

[0079] In formula (4), (u, v) is the image coordinate of each pixel, (u i ,v i ) is the image coordinate of the i-th speckle point, I i is the gray value of the i-th speckle point, R is the radius of the speckle point, (a 0 ,a 1 ,a 2 ,b0 ,b 1 ,b 2 ) is the affine deformation parameter. Such as Image 6 Shown, according to the set parameters (M=16718, I i =rand(100~255), and R=3 pixels) to g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com