Auxiliary bundling equipment for automatic portioning of vegetables

A vegetable and component technology, which is applied in the direction of packaging fruits/vegetables, parts of bundling machinery, packaged food, etc., can solve the problems of low work intensity and efficiency, and scattered and scattered bundles of vegetables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

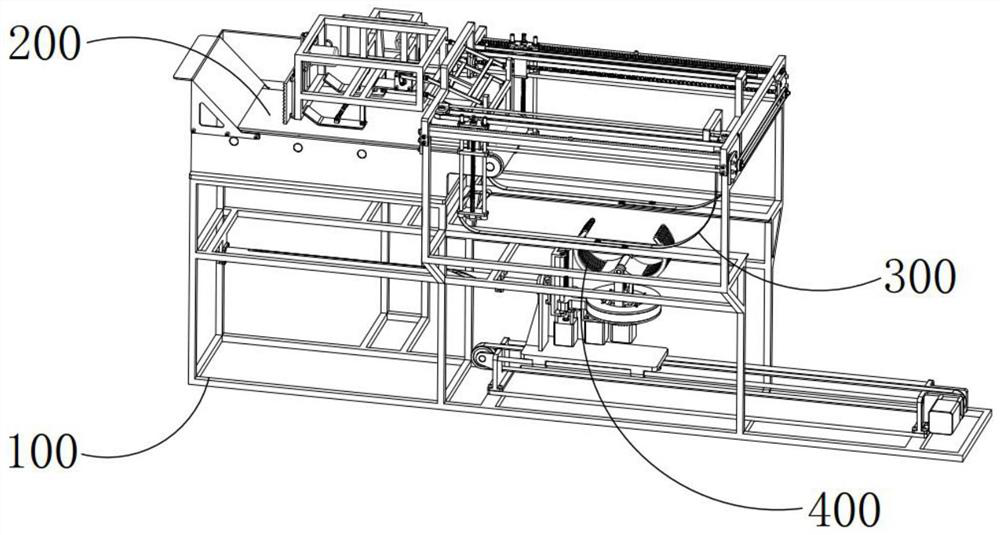

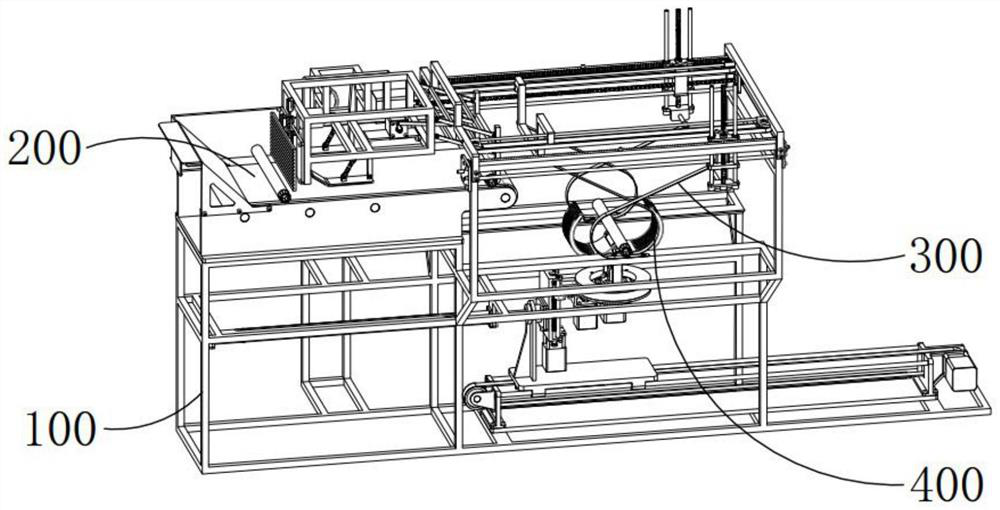

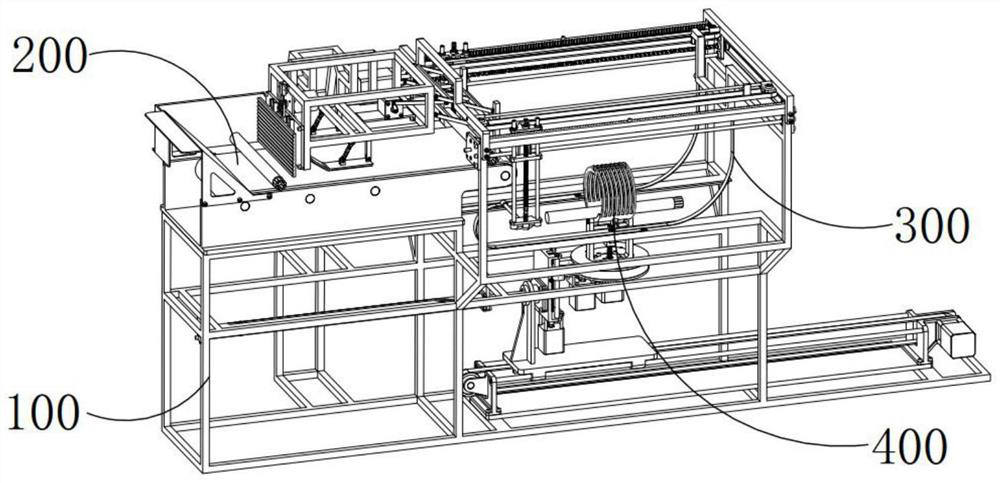

[0092] An auxiliary bundling device for automatic portioning of vegetables, which includes a rectangular bottom frame 100 arranged in a hollowed out shape, a blanking component device 200 arranged at one end of the top of the bottom frame 100 along the length direction, and a bottom frame 100 arranged at the other end along the length direction in the middle of the bottom frame 100. The gathering part 300 of the bottom frame 100 and the manipulator part 400 arranged at the other end along the length direction at the bottom of the chassis 100, the output end of the blanking component device 200 is docked with the input end of the gathering part 300, and the output end of the gathering part 300 is docked with the manipulator part 400, The blanking component device 200 is used to stack vegetables in bunches and quantitatively transport the blanking to the gathering part 300. The gathering part 300 is used to accept the bunches of quantitative components and convolute them. The mani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com