Equipment failure early warning system based on model full life cycle management

A full life cycle, equipment failure technology, applied in data processing applications, calculations, electrical testing/monitoring, etc., can solve problems such as early warning errors, accuracy decline, and reliance on machine learning modeling methods, so as to reduce operation and maintenance costs and reduce The effect of equipment downtime accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

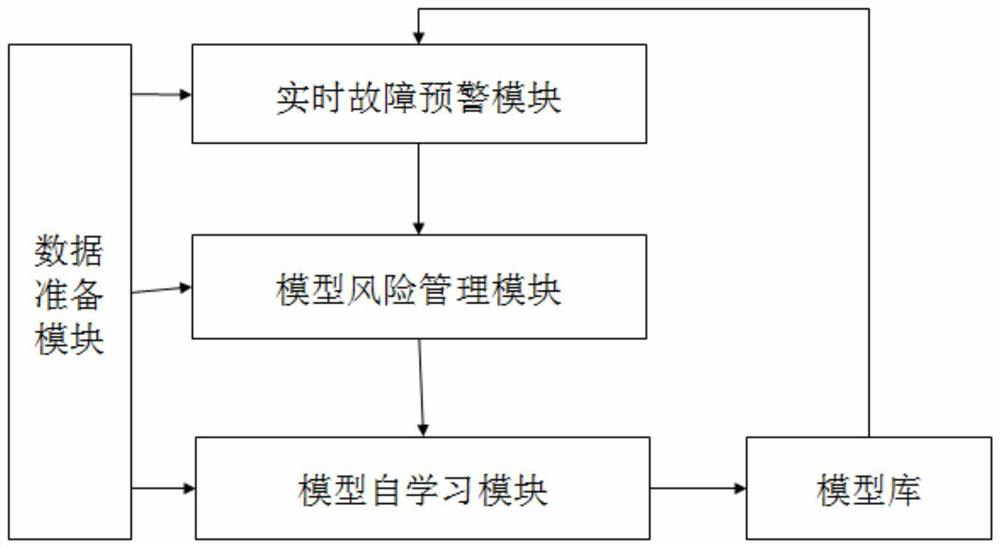

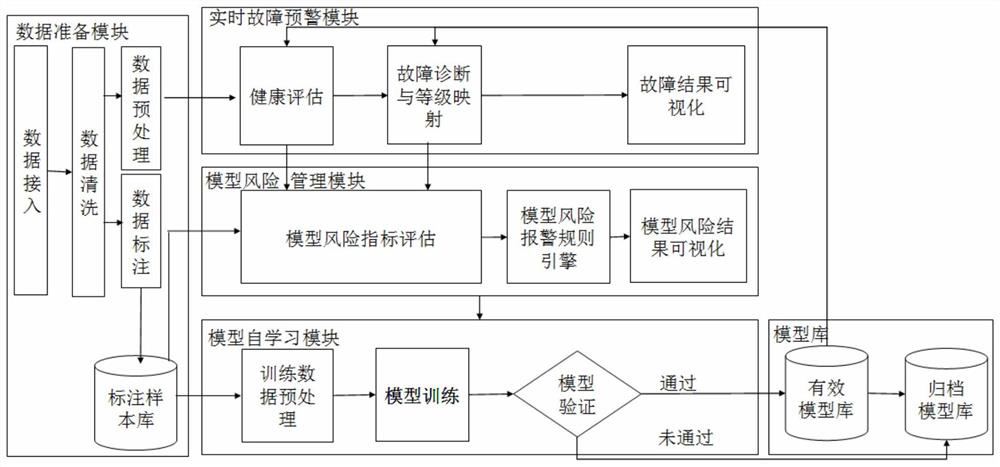

[0020] Such as figure 1 As shown, the equipment failure early warning system based on model lifecycle management in this application includes a data preparation module, a real-time failure warning module, a model risk management module, a model self-learning module and a model library.

[0021] The data preparation module reads in external real-time data and performs preprocessing, transfers the processed external real-time data to the real-time fault early warning module for analysis, and transfers the accumulated labeled samples to the model risk management module for relia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com