Cast-in-situ bored pile concrete pouring height detection device and use method

A technology of height detection device and bored pile, which is applied in the test of foundation structure, construction, foundation structure engineering, etc., to achieve the effect of improving the construction progress and improving the quality of the pile body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

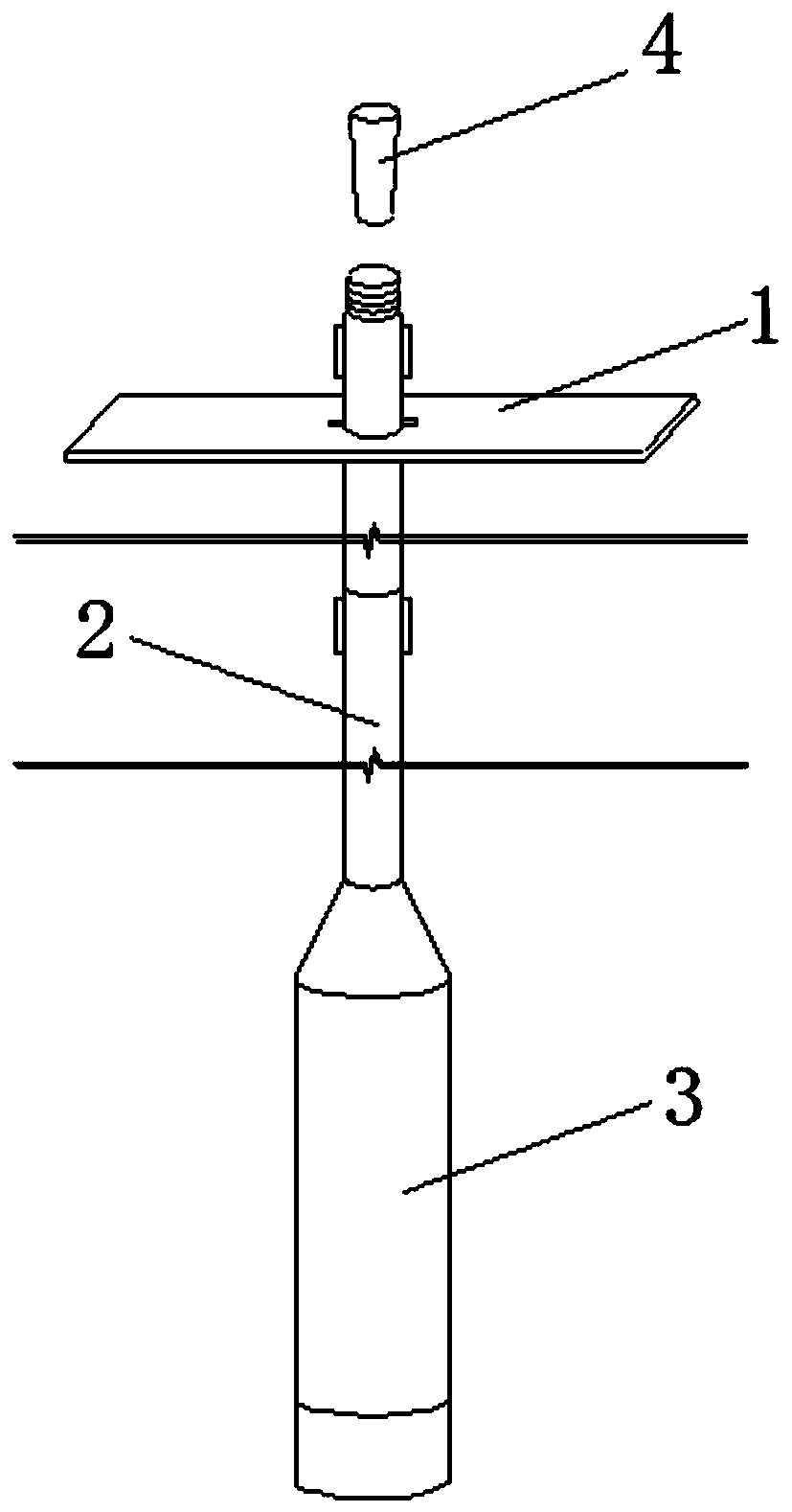

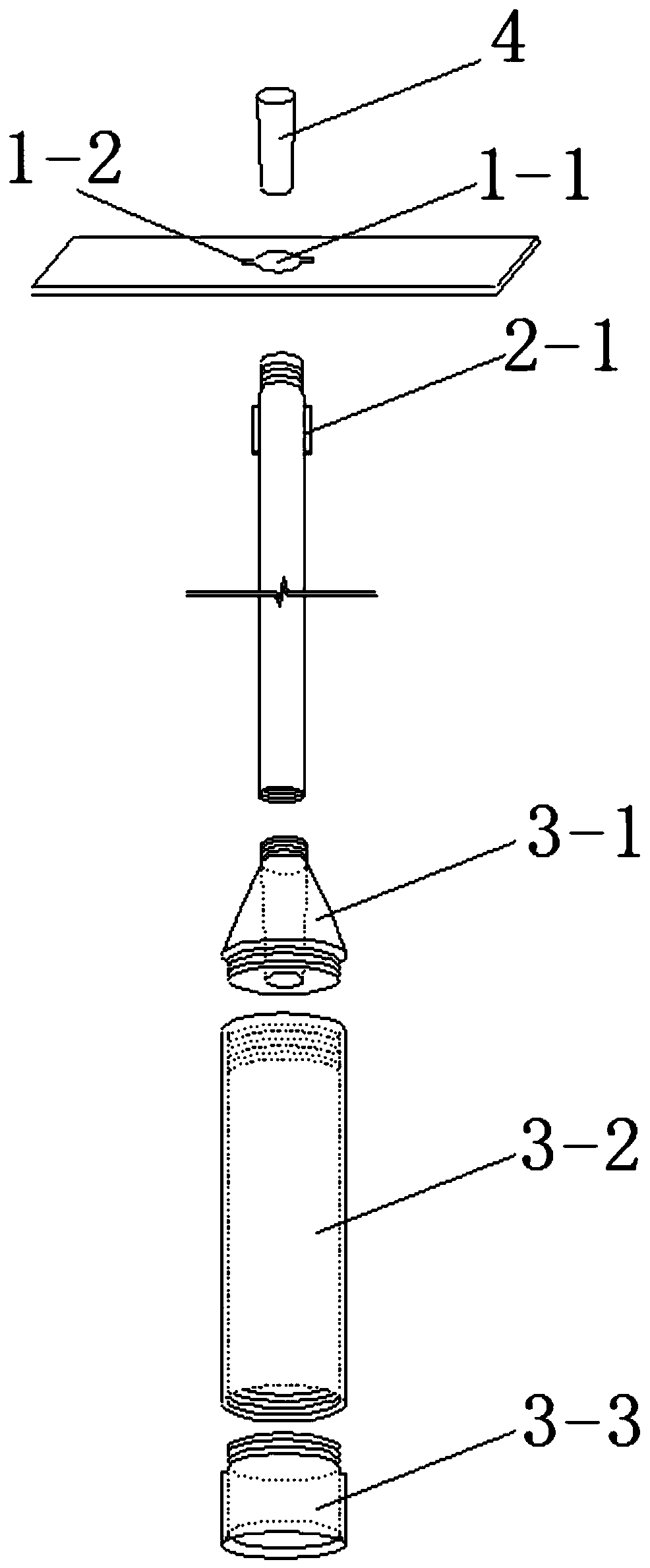

[0041] Such asfigure 1 , 2 As shown, a device for detecting the pouring height of bored pile concrete includes an orifice tray (1), a connecting pipe (2), a coring pipe (3) and a stopper rod (4).

[0042] The center of the orifice tray (1) is provided with an orifice (1-1), and two gaps (1-2) are provided along the diameter of the orifice (1-1); the connecting pipe (2) is a multi-section combined structure, and each The upper end of the connecting pipe is provided with a lug (2-1); the core pipe (3) is composed of a different-diameter pipe collar (3-1), a pipe body (3-2) and a pipe head (3-3) connected in sequence , the reducing pipe collar (3-1) connects the connecting pipe (2) and the pipe body (3-2) into a whole.

[0043] Assemble the different-diameter pipe collar (3-1), pipe body (3-2) and pipe head (3-3) into a core pipe (3); connect the first connecting pipe (2) and the different-diameter pipe collar (3- 1) Carry out threaded connection, and at the same time put the o...

Embodiment 2

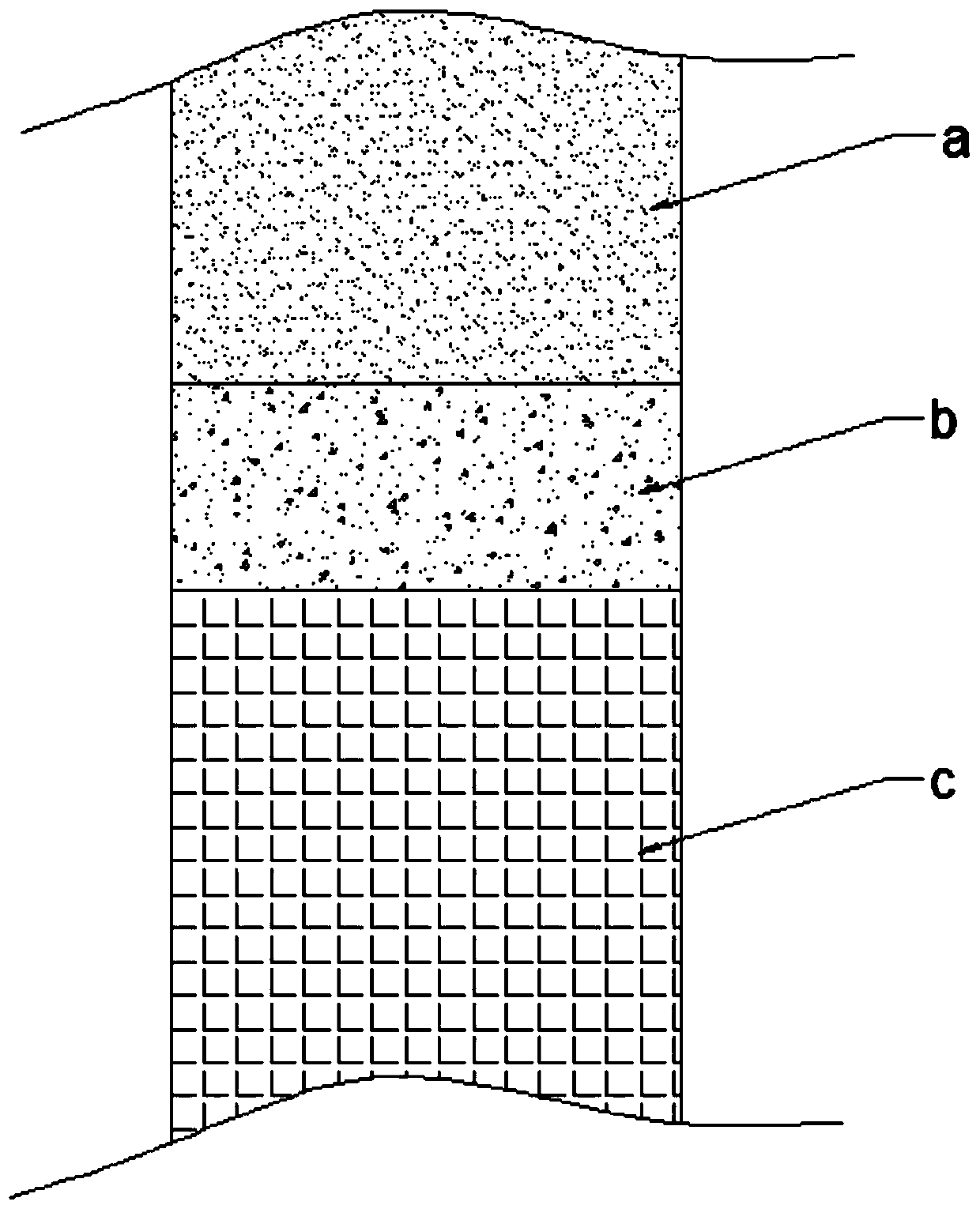

[0061] The difference between this embodiment and Embodiment 1 is that the tube body (3-2) of the core tube can be made of transparent material, such as glass or transparent plastic, so that in step ⑦, it is not necessary to pour out the core tube (3) As long as the outer wall of the pipe body (3-2) is cleaned, the position of the interface between the concrete layer and the mixed layer can be directly observed, and then the pouring height of the cast-in-place concrete can be measured.

Embodiment 3

[0063] Further, the orifice tray (1) is a steel rectangular backing plate, the length of which is usually twice the diameter of the borehole, and its rigidity and thickness are based on the weight that can bear the core pipe (3) and the N-section connecting pipe (2) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com