Air-captive structure for inflatable tire

A technology for inflatable tires, applied to tire parts, transportation and packaging, vehicle parts, etc., can solve the problems of air leakage, high cost, high manufacturing cost, etc., and achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific examples.

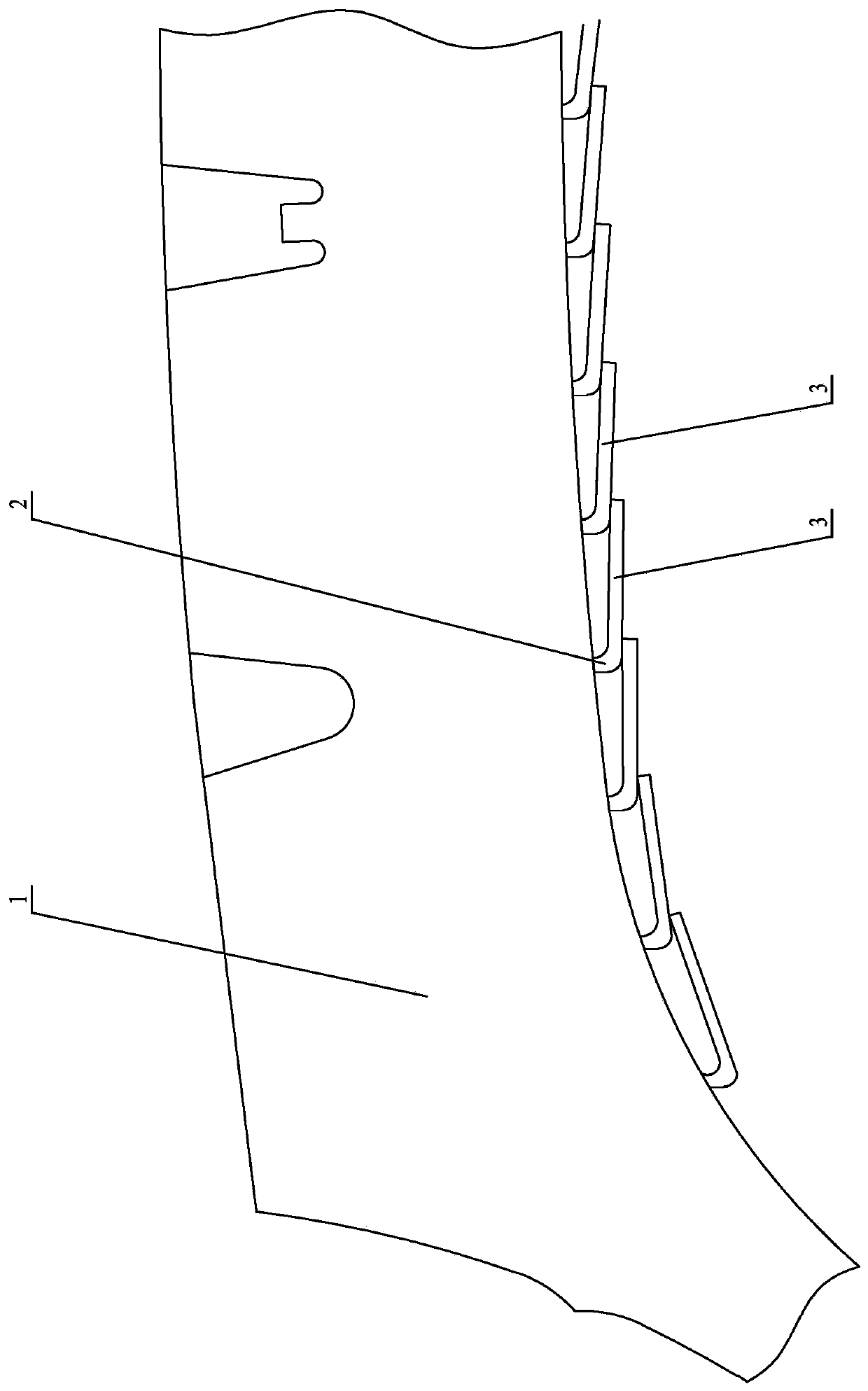

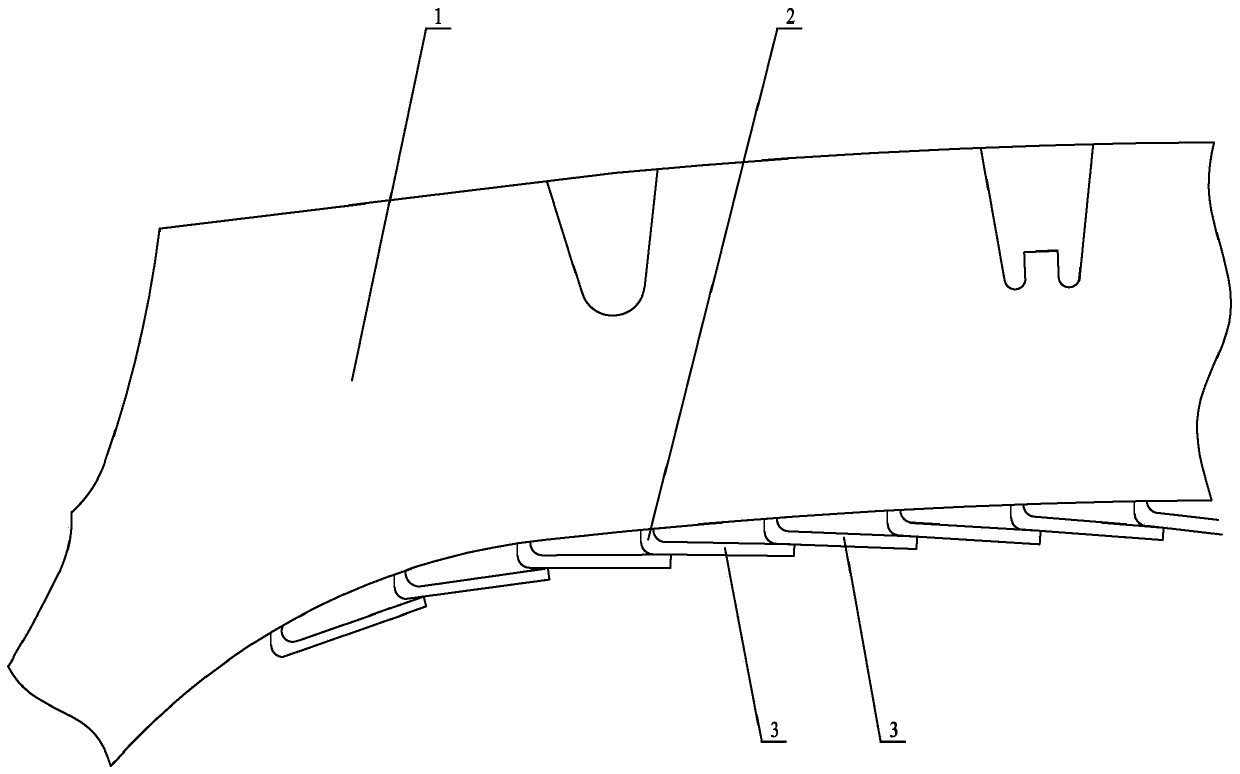

[0009] In the air retaining structure of the pneumatic tire of the present invention, several leak-proof film roots 2 are fixed on the inner wall of the crown part of the tire carcass 1, and a piece of leak-proof film 3 is uniformly connected to each leak-proof film root 2 , the connection between the leak-proof film root 2 and the leak-proof film 3 is preset at an obtuse angle, and all the leak-proof films 3 are tilted to the right; among the two adjacent leak-proof films 3, the leak-proof film 3 on the left is The right-hand end of the frame rides on the left-hand end of the leak-proof film 3 positioned on the right side.

[0010] The connecting part of the leak-proof film root 2 and the leak-proof film 3 is preset at 90-100°.

[0011] In the present invention, the connecting part of the leak-proof film root 2 and the leak-proof film 3 is preset at an obtuse angle, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com