Printing equipment

A technology of printing equipment and printing mechanism, which is applied to printing devices, printing, typewriters, etc., can solve the problems of reciprocating movement of nozzles and affecting stability, and achieve the effect of improving stability and avoiding oblique spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

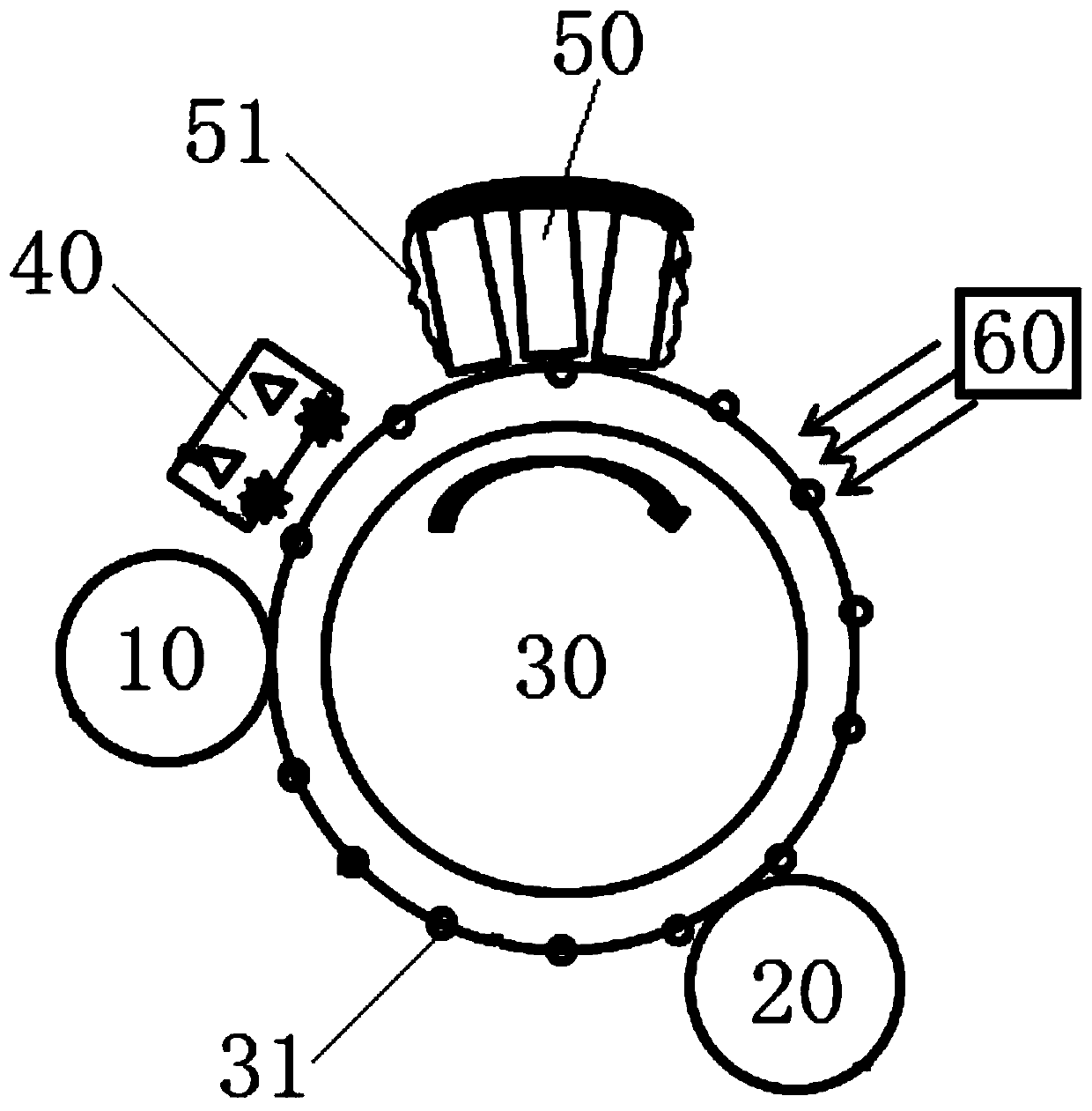

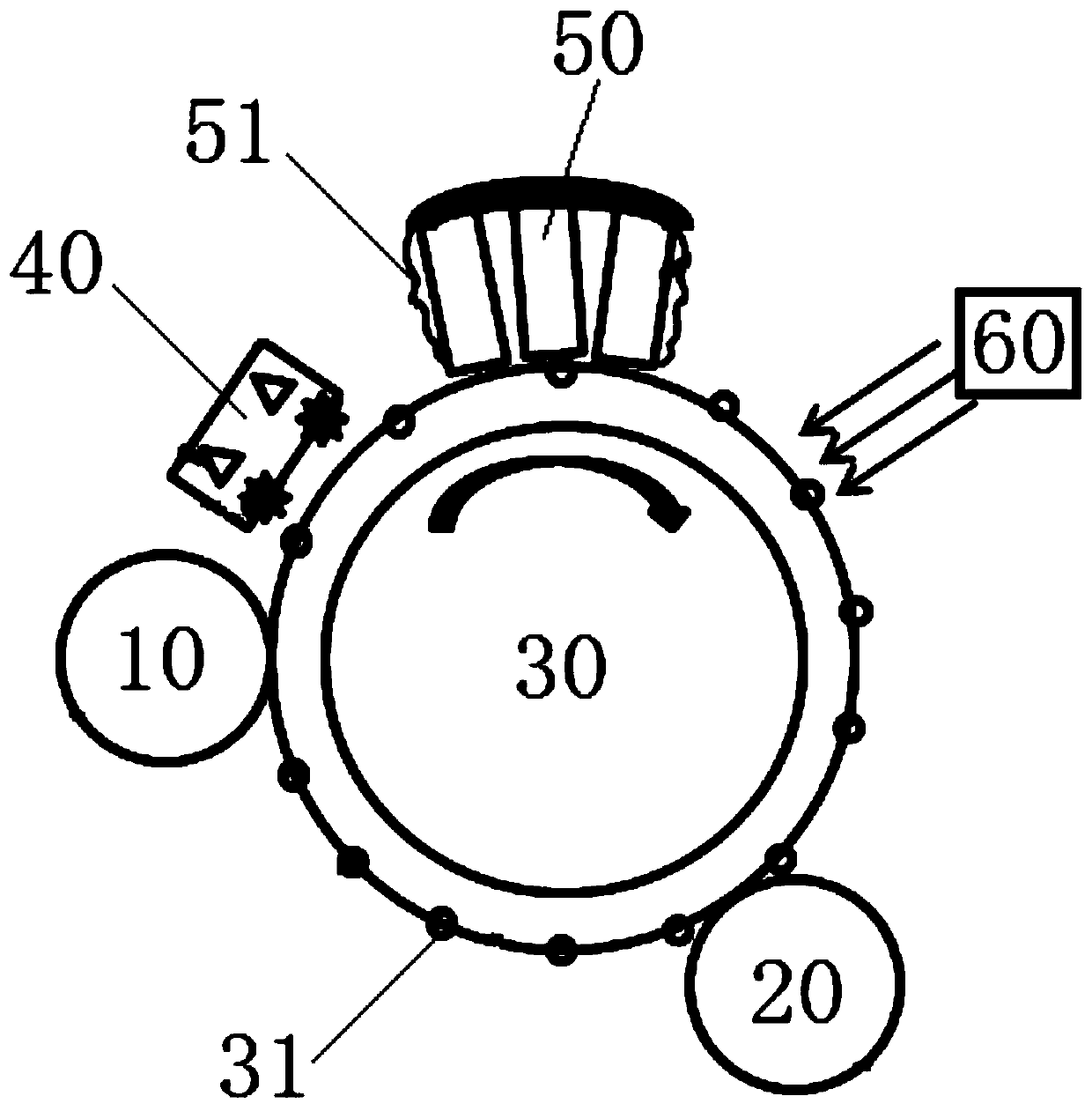

[0020] The invention provides a printing device, such as figure 1 As shown, the printing device includes a printing mechanism, a paper feeding mechanism 10 and a paper output mechanism 20, the printing mechanism includes a conveying device and a fixedly installed printing device, the paper feeding mechanism 10 can provide substrates to the conveying device, The printing device can define a printing area, the conveying device can transport the printed matter so that the printed matter passes through the printing area, and the paper output mechanism 20 can receive the printed matter on the conveying device.

[0021] With the printing equipment provided by this application, the substrate is supplied to the conveying device of the printing mechanism through the paper feeding mechanism 10, and the conveying device can transport the substrate through the printing area defined by the printing device, so that the printing device does not need to move. Printing, the printed substrate c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap