A gravity unloading device in the process of assembly and debugging of spacecraft light parts

A technology of gravity unloading and parts, applied in simulation devices, shock absorbers, shock absorbers and other directions of space navigation conditions, can solve problems such as mechanical damage and precise control of unfavorable loads, and achieve low friction resistance and rapid movement response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

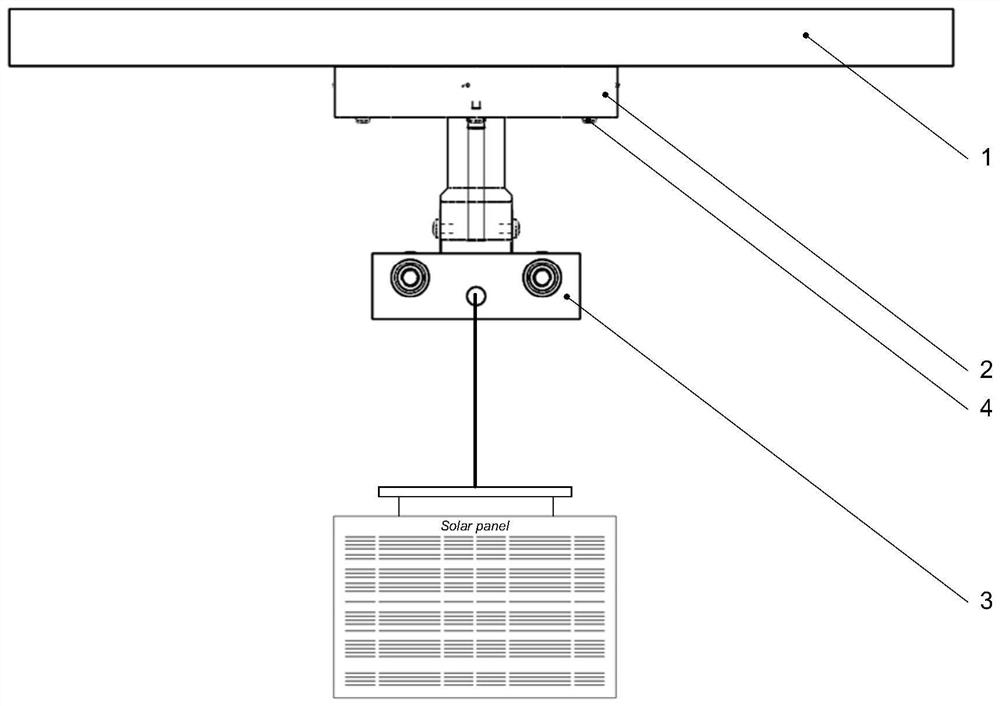

[0026] A gravity unloading device in the process of assembly and debugging of lightweight components of a spacecraft, such as figure 1 As shown, it includes a horizontal top plate 1, an air foot mechanism 2, a spring mechanism 3 and a protective mechanism 4. The horizontal top plate 1 is precisely installed horizontally on a large mounting bracket, and has high flatness and surface roughness. The flatness of the flat top plate The error is not less than 10μm, and the surface roughness is not less than 0.4. It provides a reference plane for plane movement for the air foot mechanism 2, and has a magnetic permeability, and can prevent the suspended parts from falling through electromagnetic adsorption in an emergency.

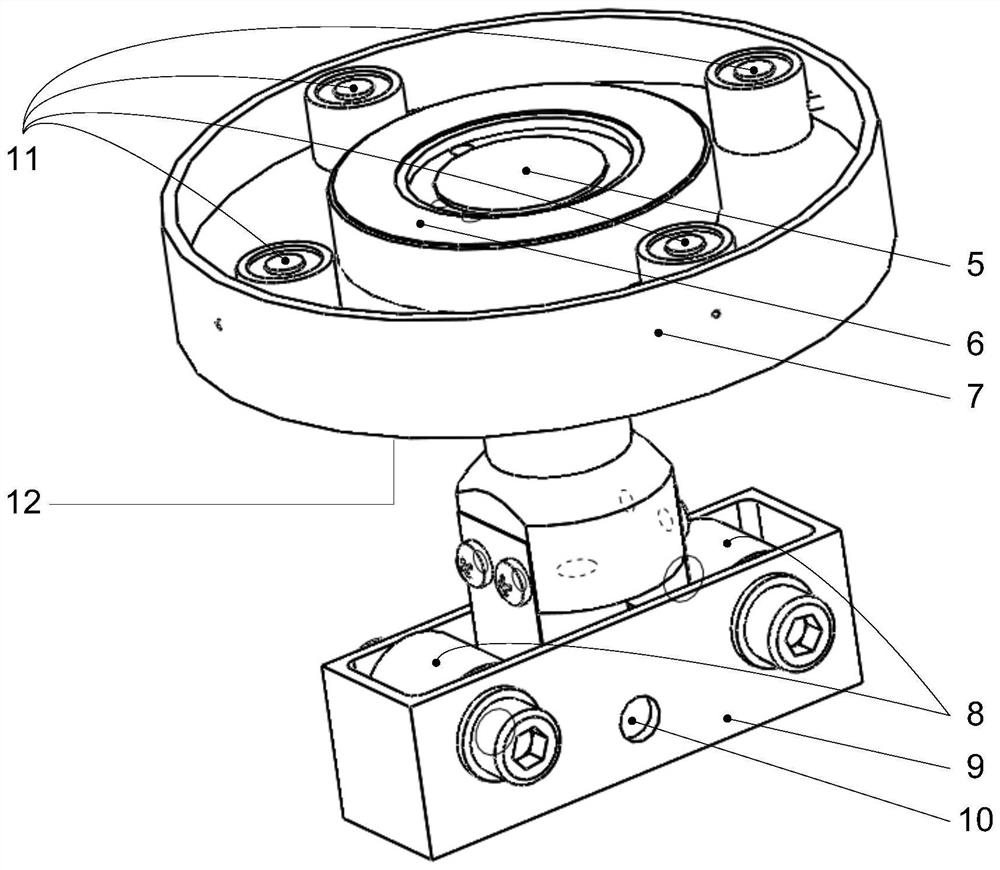

[0027] Such as figure 2 As shown, the upper part of the air foot mechanism 2 and the lower part of the horizontal top plate 1 have negative pressure or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com