Ethanol inventory replenishment strategy based on multi-objective particle swarm optimization algorithm

A multi-objective particle swarm and optimization algorithm technology, applied in computing, instruments, data processing applications, etc., can solve problems such as high dependence on people, waste of resources, and inability to control the quantity of replenishment well, so as to improve inventory turnover Efficiency, reducing the total cost of inventory, and promoting the effect of inventory optimization control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

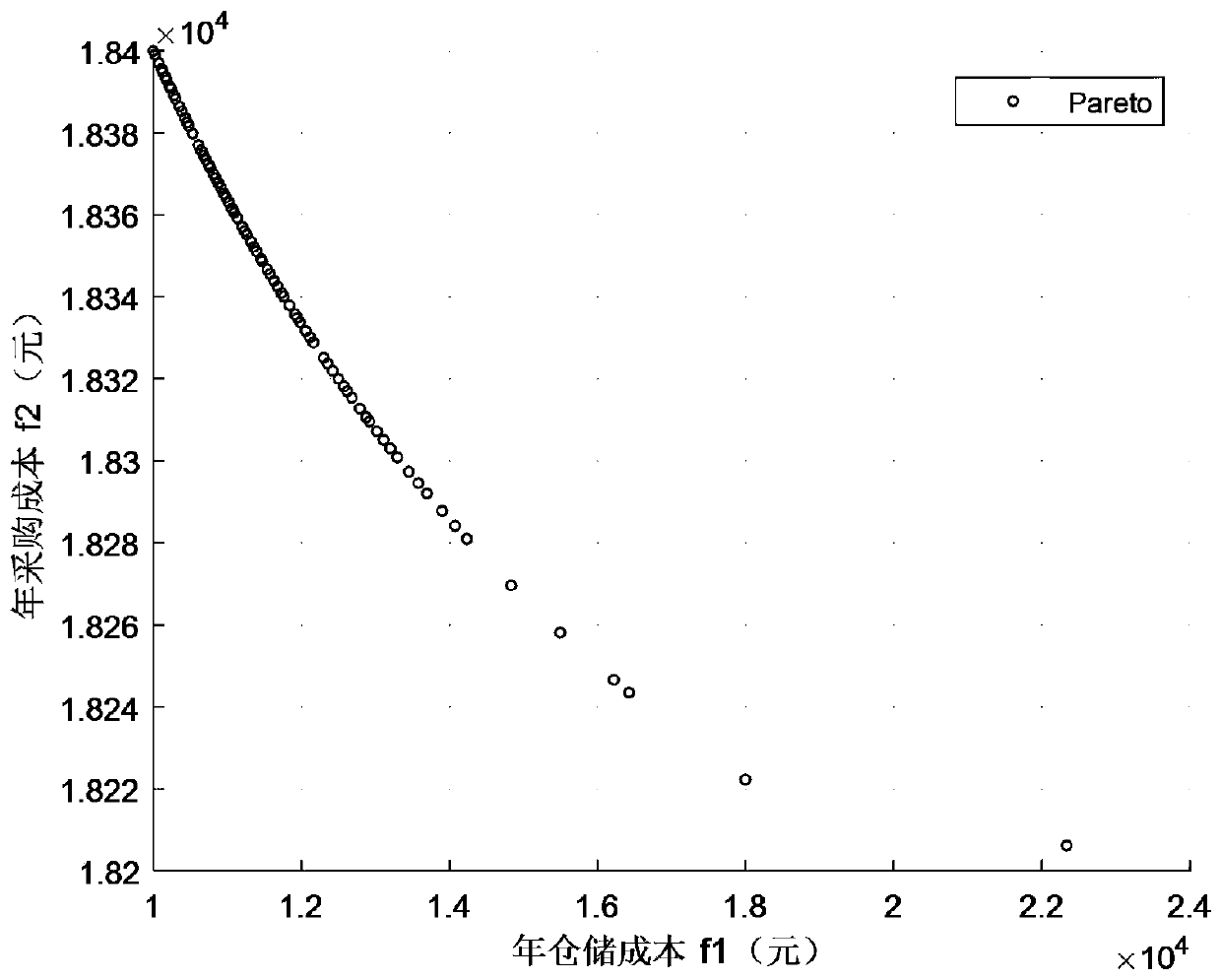

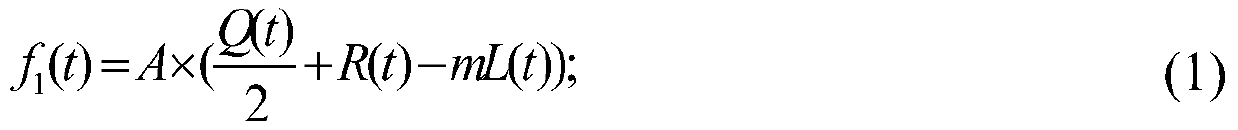

[0031] (1) Select the variables related to ethanol storage cost and procurement cost as follows: replenishment batch Q(t), starting replenishment strategy inventory balance R(t), delivery time L(t);

[0032] (2) Establish ethanol storage cost and purchase cost models:

[0033]

[0034]

[0035]

[0036] Among them, f 1 (t) is the ethanol storage cost model for the tth period, including management cost, accident risk cost, and deterioration loss cost; f 2 (t) is the ethanol procurement cost model in the tth cycle, including ordering cost, transportation cost, and emergency delivery contingency cost; taking one year as a cycle, Q(t) is the fixed cost of each replenishment in the tth cycle Replenishment batches; R(t) is the inventory balance of each replenishment strategy in the t-th cycle; L(t) is the delivery time of each t-th cycle; m is the expected value of the daily ethanol demand, m= 5 bottles; M is the expected value of the total ethanol demand in a single cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com