Mobile plugging structure

A technology of plug-in structure and movable connection, applied in the direction of connection, contact parts, parts of connection device, etc., can solve the problems of difficult plug-in and loose connection, and achieve the effect of easy plug-in and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

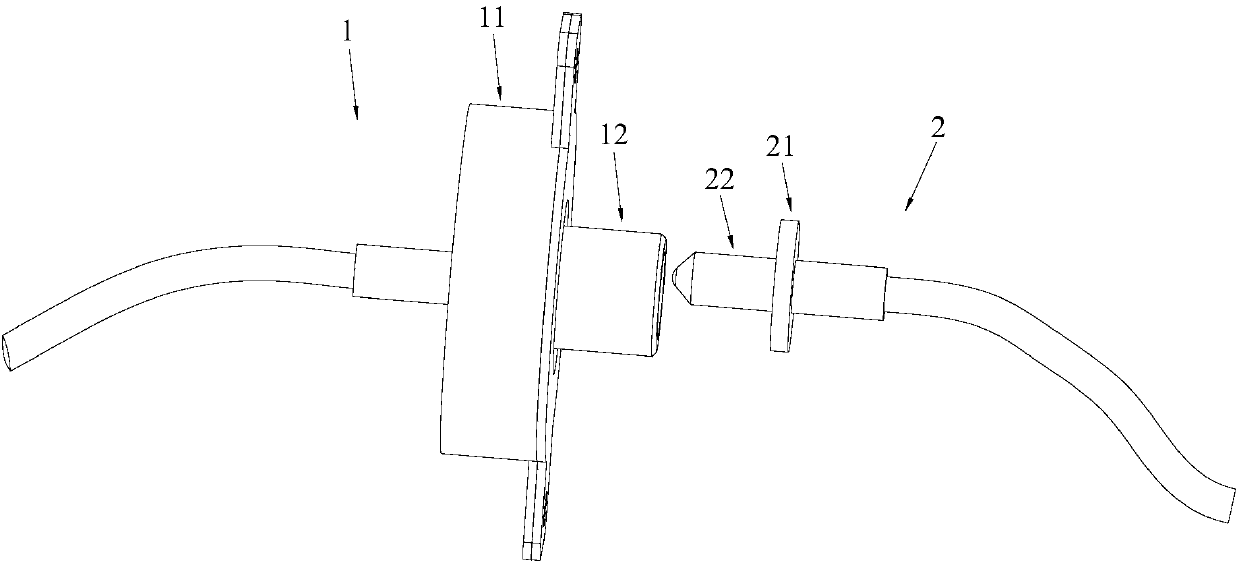

[0029] Please also refer to Figure 1 to Figure 3 , the movable plug structure provided by the present invention will now be described. The movable plug structure includes a first plug assembly 1 and a second plug assembly 2, the first plug assembly 1 includes a first mount 11 and a first plug 12 connected to each other, and the second plug assembly 2 includes interconnected The second mounting base 21 and the second plug 22, the first plug 12 and the second plug 22 are plugged together, in particular, the first plug 12 and the first mounting base 11 and the second plug 22 and the second mounting base 21 are at least One group is movable connection, that is, the movable plug structure of the present invention has the following three situations: the first plug 12 is movably connected with the first mounting base 11, and the second plug 22 is fixedly connected with the second mounting base 21; or, the first The plug 12 is movably connected to the first mounting base 11, and the...

Embodiment approach

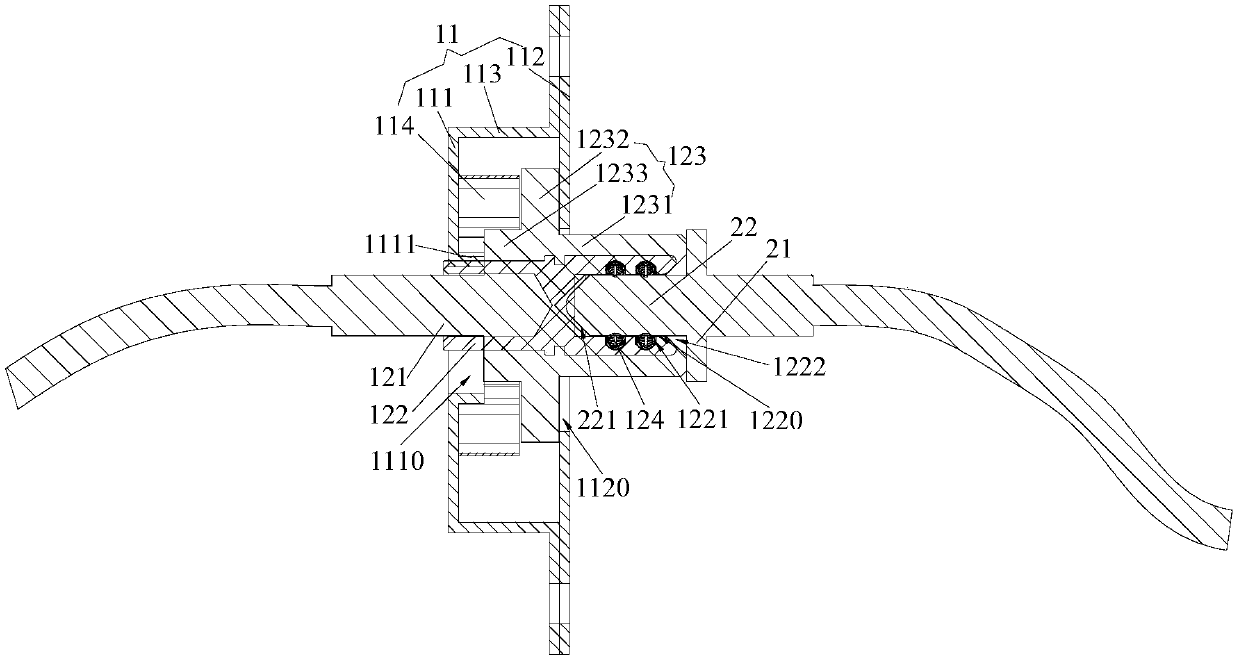

[0037] Further, see figure 2 , as a specific embodiment of the movable plug-in structure provided by the present invention, the above-mentioned first limiting plate 111 is provided with a first limiting hole 1110, and the first limiting hole 1110 runs through the first limiting plate 111 and the first The sleeve 1111 and the second limiting plate 112 are provided with a second limiting hole 1120 . The movable part 123 includes a first cylinder 1231 and a second cylinder 1232, the second cylinder 1232 is connected between the first cylinder 1231 and the second sleeve 1233, and the outer diameter of the first cylinder 1231 is smaller than that of the second cylinder 1232 and the inner diameter of the second limiting hole 1120, the outer diameter of the second cylinder 1232 is greater than the inner diameter of the second limiting hole 1120 and the inner diameter of the first limiting hole 1110, the outer diameter of the cable 121 is smaller than the first The inner diameter of...

Embodiment 2

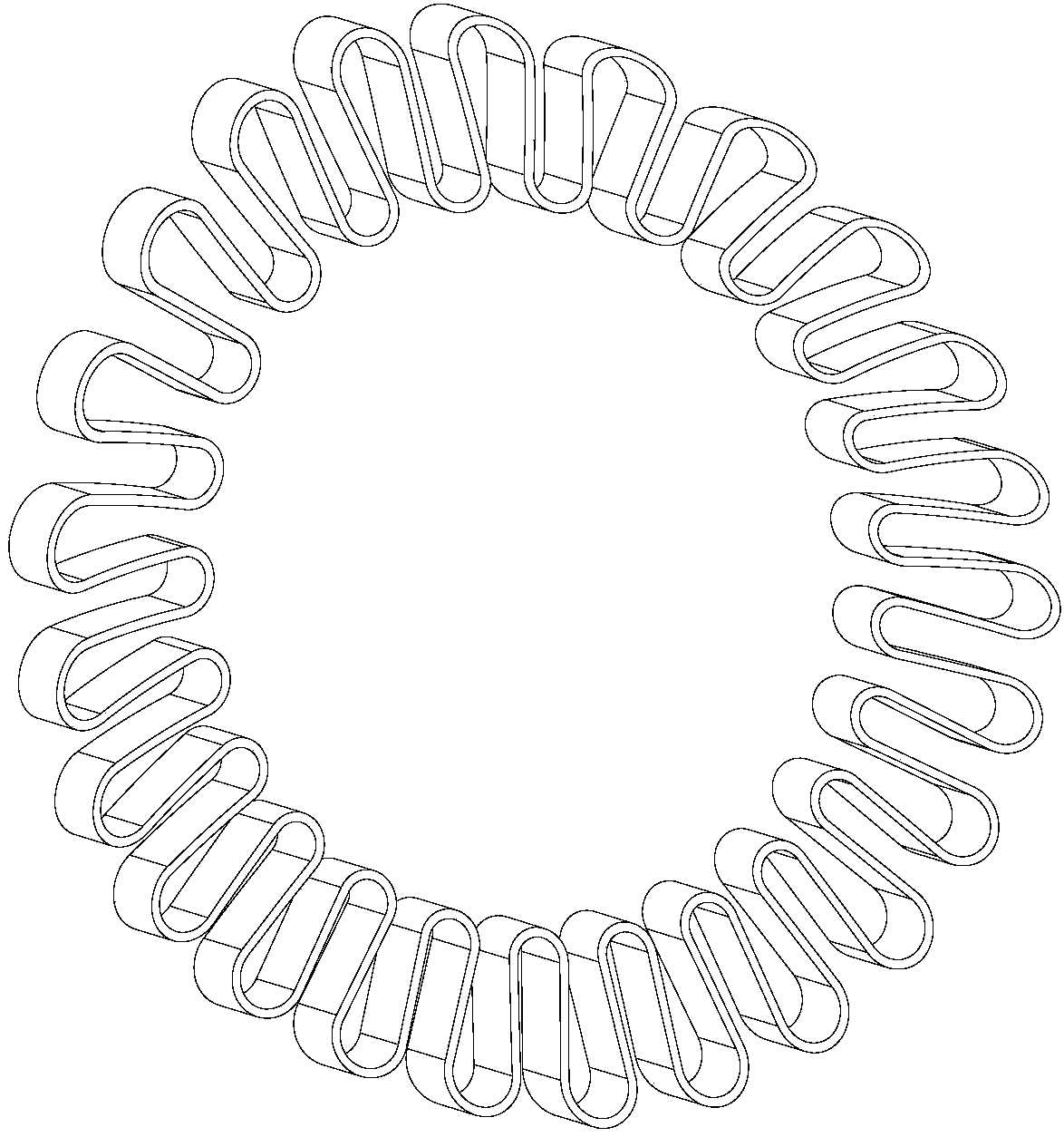

[0042] The technical characteristics of the active plug structure in this embodiment are basically the same as those in Embodiment 1, the difference is: please refer to Figure 4 and Figure 6 The above-mentioned movable part 123 includes a socket part 1234 and two movable parts 1235, and the above-mentioned first installation seat 11 corresponding to the two movable parts 1235 includes two first limiting plates 111, two second limiting plates 112, two connecting bodies 113 and two Reset part 114, see Figure 5 , the sleeve part 1234 covers the connection between the cable 121 and the connector 122, and the two movable parts 1235 are respectively connected to the opposite sides of the sleeve part 1234, and the movable part 1235 can be moved to stop the second limiting plate 112 and the Between the first limiting plates 111 , the second sleeve 1233 protrudes from the movable portion 1235 . When the movable socket structure of this embodiment is working, the second limiting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com